Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Blower position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

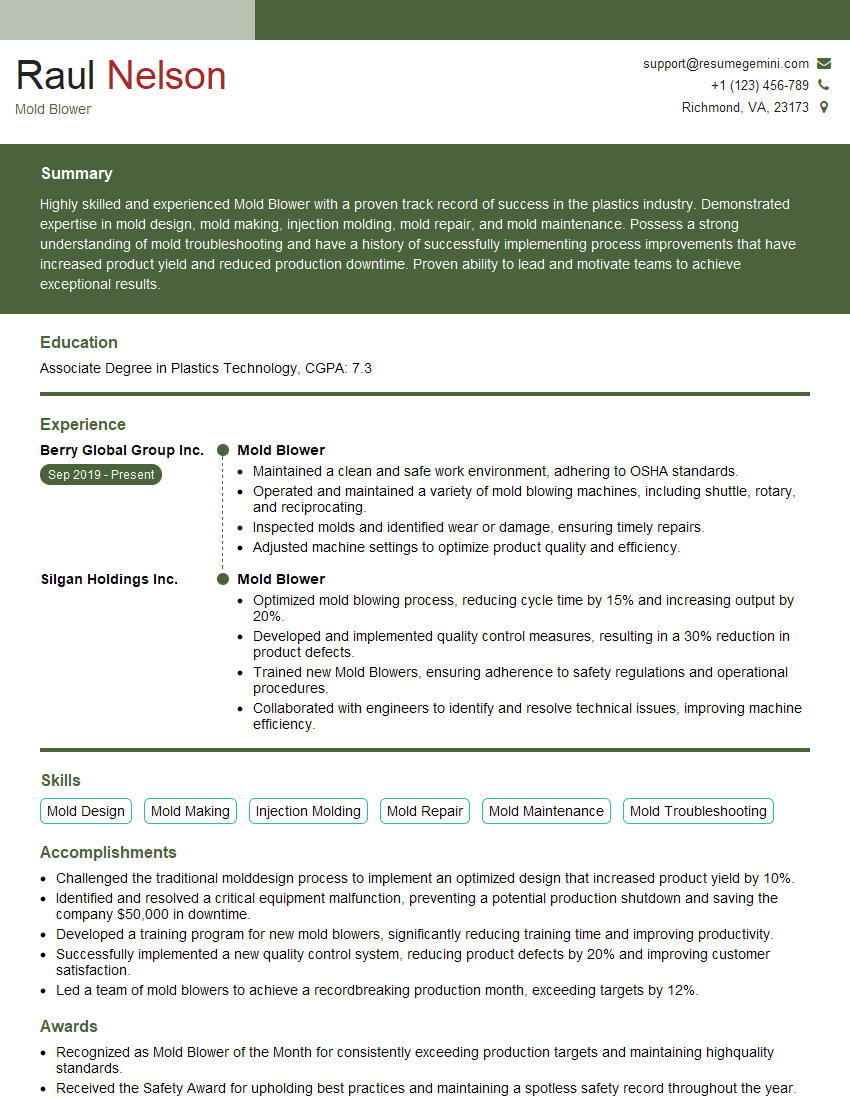

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Blower

1. What is the process of mold blowing? Describe the steps involved.

Mold blowing is a manufacturing process used to create hollow plastic products. It involves the following steps:

- A mold is created with the desired shape of the product.

- Molten plastic is injected into the mold.

- The mold is closed and the plastic is forced into the shape of the mold.

- The mold is cooled and the plastic product is ejected.

2. What are the different types of molds used in mold blowing?

Injection molds

- Used to create products with complex shapes and details.

- Made from metal or plastic.

- Require high-pressure injection molding machines.

Blowing molds

- Used to create products with simple shapes and large volumes.

- Made from metal or plastic.

- Require lower-pressure blowing molding machines.

3. What are the key factors that affect the quality of mold blown products?

The following factors affect the quality of mold blown products:

- The design of the mold

- The type of plastic used

- The injection or blowing pressure

- The mold temperature

- The cooling time

4. What are the common defects that can occur during mold blowing?

The following are some common defects that can occur during mold blowing:

- Flash

- Sink marks

- Warping

- Bubbles

- Cracks

5. How do you troubleshoot mold blowing defects?

To troubleshoot mold blowing defects, you need to:

- Identify the defect

- Determine the cause of the defect

- Take corrective action

6. What are the safety precautions that must be observed when operating mold blowing machines?

The following safety precautions must be observed when operating mold blowing machines:

- Wear appropriate safety gear

- Keep the work area clean and free of debris

- Follow the manufacturer’s instructions for operating the machine

- Never reach into the mold while the machine is operating

- Shut off the machine and disconnect the power before performing any maintenance

7. How do you maintain mold blowing machines?

To maintain mold blowing machines, you need to:

- Clean the machine regularly

- Inspect the machine for wear and tear

- Lubricate the machine as needed

- Calibrate the machine according to the manufacturer’s instructions

8. What are the automation technologies used in mold blowing?

The following automation technologies are used in mold blowing:

- Automatic mold changing

- Automatic part ejection

- Automatic quality control

9. What are the advantages of using mold blowing to manufacture plastic products?

The following are some of the advantages of using mold blowing to manufacture plastic products:

- Can produce products with complex shapes and details

- Can produce products with large volumes

- Is a relatively fast and efficient process

- Produces products with high quality and consistency

10. What are the challenges of mold blowing?

The following are some of the challenges of mold blowing:

- High initial investment cost

- Requires skilled labor

- Can be difficult to produce products with tight tolerances

- Can be difficult to produce products with large amounts of detail

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Blowers are accountable for shaping, blowing, and adjusting molds used in glass manufacturing. They ensure the production of high-quality glass products while maintaining safety and efficiency standards.

1. Mold Preparation and Maintenance

Mold Blowers prepare and maintain molds by cleaning, inspecting, and repairing them. They ensure that molds meet quality standards and are ready for production.

2. Glass Blowing

Mold Blowers operate machines that blow molten glass into molds to create glass products such as bottles, jars, and containers. They adjust temperature and pressure settings to ensure the production of quality products.

3. Mold Adjustment and Repair

Mold Blowers continuously monitor molds and make necessary adjustments to ensure they meet quality standards. They identify and repair defects in molds to maintain production efficiency.

4. Quality Control

Mold Blowers conduct quality control checks on the glass products produced. They inspect products for defects and ensure they meet the required specifications.

Interview Tips

Interview preparation is crucial for success. Here are some tips to help you ace your Mold Blower interview:

1. Research the Company and Job Description

Familiarize yourself with the company’s history, values, and operations. Thoroughly review the job description to understand the specific responsibilities and requirements of the role.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Practice answering questions related to your glass blowing skills, mold preparation experience, and quality control procedures.

3. Highlight Your Experience and Skills

During the interview, emphasize your relevant experience in mold preparation, glass blowing, and mold adjustment. Quantify your accomplishments and provide specific examples to demonstrate your skills.

4. Ask Insightful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Ask about the company’s growth plans, safety procedures, and opportunities for professional development.

5. Follow Up

After the interview, send a thank-you note to the interviewer. Reiterate your interest in the position and highlight how your skills and experience align with the company’s needs.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mold Blower, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mold Blower positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.