Are you gearing up for a career in Mold Closer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mold Closer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

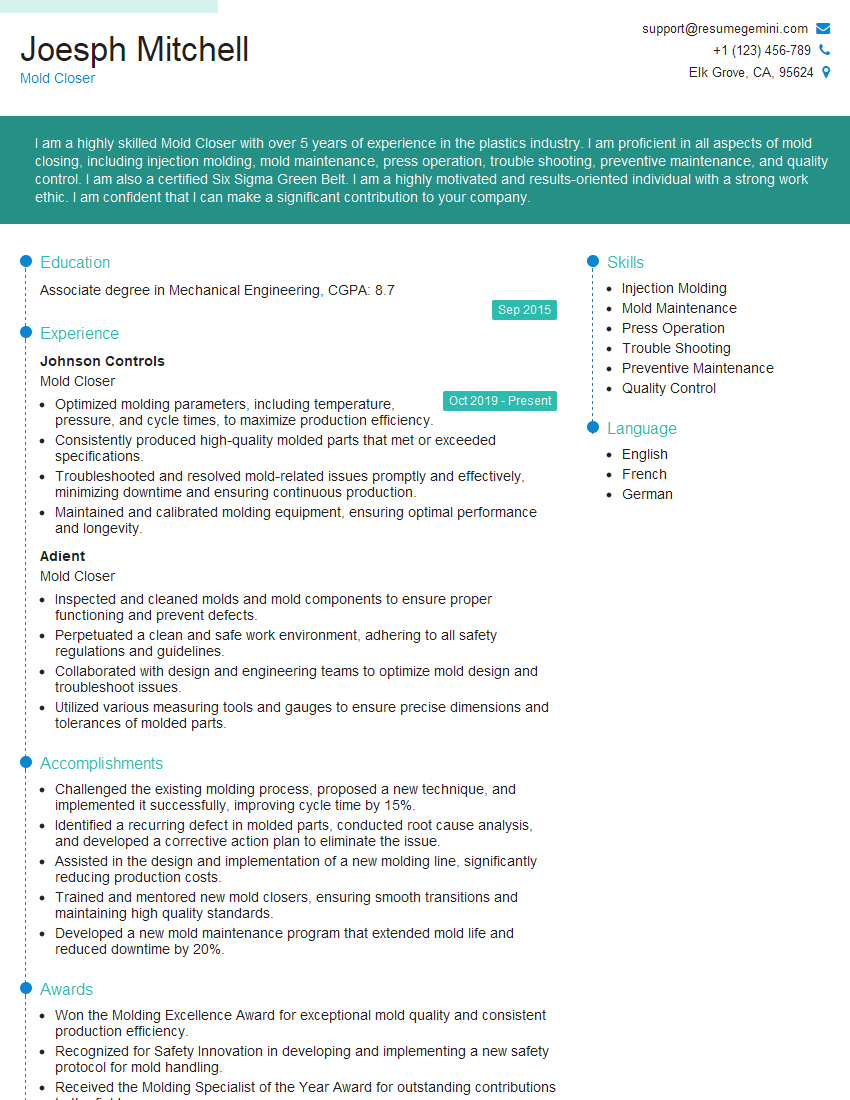

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Closer

1. What is the purpose of using mold release agents?

Mold release agents are essential for the successful molding process, as they prevent the molded part from sticking to the mold. They work by forming a thin film between the mold and the material being molded, which reduces friction and allows the part to be easily removed from the mold.

- Prevents sticking of the molded part to the mold

- Reduces friction

- Ensures easy removal of the part from the mold

- Improves the surface finish of the molded part

- Extends the life of the mold

2. What are the different types of mold release agents?

There are several types of mold release agents available, each with its own advantages and disadvantages. The most common types include:

Solvent-based release agents

- Volatile organic compounds (VOCs) present in the solvent can be harmful to health

- Environmental regulations and safety concerns limit their use

Water-based release agents

- Environmentally friendly and non-toxic

- Less effective than solvent-based release agents

Semi-permanent release agents

- Applied to the mold surface and can withstand multiple molding cycles

- High temperature resistance

- Can cause build-up on the mold surface

Internal release agents

- Added to the molding material itself

- Uniform release of the molded part from the mold

- Can affect the properties of the molded part

3. How do you determine the appropriate mold release agent for a particular application?

The choice of mold release agent depends on several factors, including:

- Type of material being molded

- Mold surface material

- Molding process and conditions

- Environmental and safety regulations

4. What are the common defects associated with the use of mold release agents?

Improper use of mold release agents can lead to several defects in the molded parts, such as:

- Sticking of the part to the mold

- Surface imperfections (e.g., pitting, discoloration)

- Reduced part strength

- Environmental contamination

5. How do you maintain and clean molds used in molding processes?

Proper maintenance and cleaning of molds are crucial to ensure their longevity and the quality of the molded parts. The following steps are typically involved:

- Regular cleaning to remove any residual materials, mold release agents, or contaminants

- Inspection for any damage or wear

- Repair or replacement of damaged or worn components

- Application of a protective coating to prevent corrosion and extend mold life

6. What are the safety precautions that should be taken when working with mold release agents?

Mold release agents can be hazardous to health, so it is essential to follow proper safety precautions when working with them. These precautions include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators

- Ensuring proper ventilation in the workspace

- Following the manufacturer’s instructions for handling and storage

- Seeking medical attention in case of exposure to mold release agents

7. What are the latest advancements in mold release technology?

The mold release industry is constantly evolving, with new technologies emerging to improve efficiency and reduce environmental impact. Some of the latest advancements include:

- Water-based mold release agents with improved performance

- Nanotechnology-based mold release agents

- Environmentally friendly and sustainable mold release agents

8. How do you stay updated on the latest trends and developments in the field of mold closing?

To stay informed about the latest trends and developments in mold closing, I regularly engage in the following activities:

- Attending industry conferences and webinars

- Reading technical journals and articles

- Consulting with experts and suppliers in the field

- Participating in online forums and discussion groups

9. What sets you apart from other candidates for this role?

I am confident that I possess the skills and experience that make me an ideal candidate for this role. My expertise in mold closing, coupled with my strong attention to detail and commitment to quality, enables me to consistently deliver exceptional results.

- Proven ability to effectively close molds and ensure proper alignment

- In-depth knowledge of mold release agents and their applications

- Experience in maintaining and cleaning molds to extend their lifespan

- Strong understanding of safety precautions and industry best practices

- Excellent communication and teamwork skills

10. How do you handle situations when you encounter unexpected challenges or issues during mold closing?

When faced with unexpected challenges or issues during mold closing, I adopt a systematic and proactive approach to resolve them effectively.

- Identify the root cause of the issue

- Evaluate possible solutions and select the most appropriate one

- Implement the solution and monitor its effectiveness

- Document the issue and the steps taken to resolve it

- Communicate with relevant stakeholders to ensure transparency and accountability

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Closer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Closer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Closers are responsible for the safe and efficient operation of mold closing machines in a manufacturing environment. They ensure that molds are properly aligned and closed, and that the correct pressure is applied to create high-quality products. Key job responsibilities include:

1. Machine Operation

Mold Closers must be able to operate mold closing machines safely and efficiently. This includes:

- Setting up and adjusting the machine according to specifications

- Loading and unloading molds

- Applying pressure to close the molds

- Monitoring the machine during operation

- Troubleshooting and resolving any issues that may arise

2. Quality Control

Mold Closers play a vital role in ensuring the quality of manufactured products. They must be able to:

- Inspect molds for defects before use

- Identify and correct any problems that may arise during the molding process

- Maintain records of all inspections and corrective actions

3. Safety

Mold Closers must always prioritize safety in the workplace. They must be aware of all safety regulations and procedures, and follow them at all times. This includes:

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Working in a clean and organized environment

4. Teamwork

Mold Closers often work as part of a team. They must be able to communicate effectively with other team members, and work together to achieve common goals. This includes:

- Collaborating with engineers and other technical staff

- Sharing knowledge and expertise with colleagues

- Supporting other team members when needed

Interview Tips

Preparing for an interview can be daunting, but there are steps you can take to increase your chances of success.

1. Research the Company

Before your interview, take some time to research the company you are applying to. This will help you understand their culture, values, and the specific role you are interviewing for. You can find this information on the company’s website, social media pages, and other online sources.

2. Practice Your Answers

Once you have a good understanding of the company and the role, you can start practicing your answers to common interview questions. Some of the most common questions include:

- Tell me about yourself.

- Why are you interested in this role?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture. If you are unsure about what to wear, it is always better to err on the side of caution and dress more formally.

4. Be Punctual

Punctuality shows respect for the interviewer’s time. Be sure to arrive for your interview on time, or even a few minutes early. If you are running late, be sure to call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, confident, and enthusiastic, and you’ll be more likely to make a good impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Closer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!