Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Cutting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

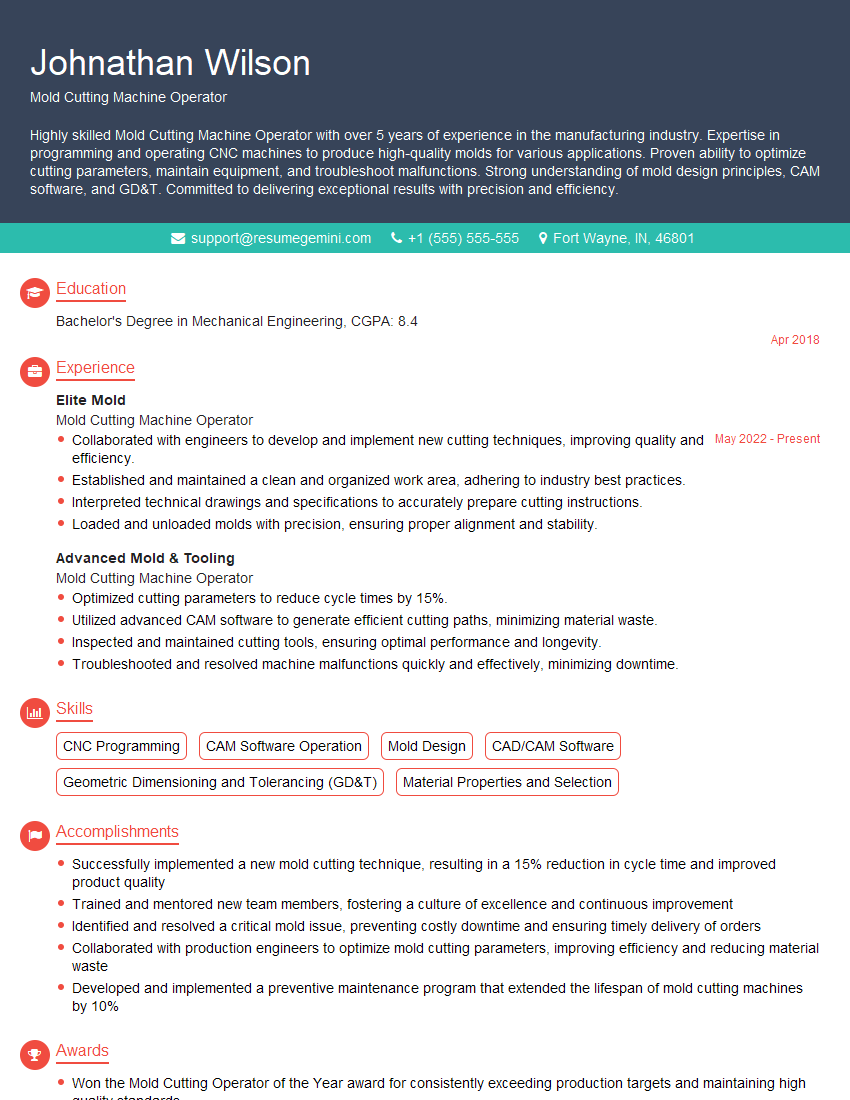

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Cutting Machine Operator

1. Explain the process of setting up a mold cutting machine?

Sample Answer:

- Secure the mold on the machine bed and align it with the cutting head.

- Select the appropriate cutting tool and insert it into the tool holder.

- Set the cutting parameters, such as speed, feed rate, and depth of cut.

2. Describe the different types of mold cutting machines and their capabilities?

of the Answer: CNC Mold Cutting Machines:

- Computer-controlled for precise cutting.

- Capable of cutting complex shapes and contours.

Subheading of the Answer: Manual Mold Cutting Machines:

- Requires skilled operators.

- Limited to straight cuts and simple shapes.

3. How do you ensure precision in mold cutting?

Sample Answer:

- Calibrating the machine and cutting tools regularly.

- Using high-quality mold materials and cutting tools.

- Following the manufacturer’s guidelines for cutting parameters.

4. Describe the different types of mold materials and their properties?

Sample Answer:

- Steel: Durable, high strength, and good thermal conductivity.

- Aluminum: Lightweight, rust-resistant, and easy to machine.

- Plastic: Inexpensive, lightweight, and resistant to corrosion.

5. How do you troubleshoot common problems encountered in mold cutting?

Sample Answer:

- Chatter: Adjust cutting parameters, check tool sharpness, or secure workpiece.

- Poor surface finish: Use finer cutting tools, adjust feed rate, or increase spindle speed.

- Tool breakage: Check tool wear, adjust cutting parameters, or use a different tool material.

6. What are the safety precautions that must be taken when operating a mold cutting machine?

Sample Answer:

- Wear appropriate safety gear, including goggles, gloves, and hearing protection.

- Secure the workpiece properly before cutting.

- Keep the work area clean and free of debris.

7. How do you calculate the cutting speed and feed rate for different mold materials?

Sample Answer:

- Refer to manufacturer’s recommendations or industry standards.

- Consider factors such as tool material, workpiece material, and desired surface finish.

- Use formulas or online calculators to determine optimal cutting parameters.

8. Explain the different methods of mold cutting, such as conventional cutting and high-speed cutting?

Subheading of the Answer: Conventional Cutting:

- Uses slower cutting speeds and lower feed rates.

- Suitable for harder materials and complex shapes.

Subheading of the Answer: High-Speed Cutting:

- Uses higher cutting speeds and faster feed rates.

- Minimizes heat generation and improves surface finish.

9. How do you maintain and calibrate a mold cutting machine?

Sample Answer:

- Regularly clean and lubricate the machine.

- Inspect and replace cutting tools as needed.

- Calibrate the machine according to manufacturer’s specifications.

10. Describe your experience in programming and operating CNC mold cutting machines?

Sample Answer:

- Proficient in programming and operating various CNC mold cutting machines.

- Developed and implemented cutting programs for complex mold designs.

- Optimized cutting parameters for different mold materials and shapes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Cutting Machine Operators are responsible for the safe and efficient operation of mold cutting machines. They use these machines to cut molds, which are used to create a variety of products, including plastic parts, metal castings, and rubber gaskets.

1. Set up and operate mold cutting machines

Mold Cutting Machine Operators must be able to set up and operate mold cutting machines safely and efficiently. This includes loading the machine with the correct mold and setting the machine’s controls.

- Load the machine with the correct mold

- Set the machine’s controls

- Start the machine and monitor its operation

- Stop the machine and unload the mold when the cutting process is complete

2. Inspect molds and cut parts

Mold Cutting Machine Operators must be able to inspect molds and cut parts for defects. They must also be able to make adjustments to the machine’s settings to ensure that the parts are cut to the correct specifications.

- Inspect molds for defects

- Inspect cut parts for defects

- Make adjustments to the machine’s settings

3. Maintain mold cutting machines

Mold Cutting Machine Operators must be able to maintain mold cutting machines. This includes cleaning the machine, lubricating its moving parts, and replacing worn-out parts.

- Clean the machine

- Lubricate the machine’s moving parts

- Replace worn-out parts

4. Follow safety procedures

Mold Cutting Machine Operators must be able to follow safety procedures. This includes wearing the proper safety gear and following the machine’s operating instructions.

- Wear the proper safety gear

- Follow the machine’s operating instructions

- Report any safety hazards to a supervisor

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to help yourself ace the interview and land the job you want.

1. Research the company and the position

Before you go on an interview, it’s important to do your research. This includes learning about the company, the position you’re applying for, and the industry. You should also be able to articulate why you’re interested in the position and why you’re the best person for the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

- Practice answering common interview questions

2. Dress professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for. You should also make sure your shoes are clean and polished.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Polish your shoes

3. Be on time

Punctuality is important, so make sure you arrive for your interview on time. If you’re running late, call the interviewer to let them know. It’s also a good idea to arrive early so you have time to relax and prepare for your interview.

- Plan your route ahead of time

- Give yourself extra time to get there

- Call the interviewer if you’re running late

4. Be confident and enthusiastic

Confidence is key in an interview. Make sure you make eye contact with the interviewer, speak clearly and concisely, and project a positive attitude. Enthusiasm is also important, so show the interviewer that you’re excited about the opportunity to work for the company.

- Make eye contact

- Speak clearly and concisely

- Project a positive attitude

- Show enthusiasm

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold Cutting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.