Are you gearing up for an interview for a Mold Designer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mold Designer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

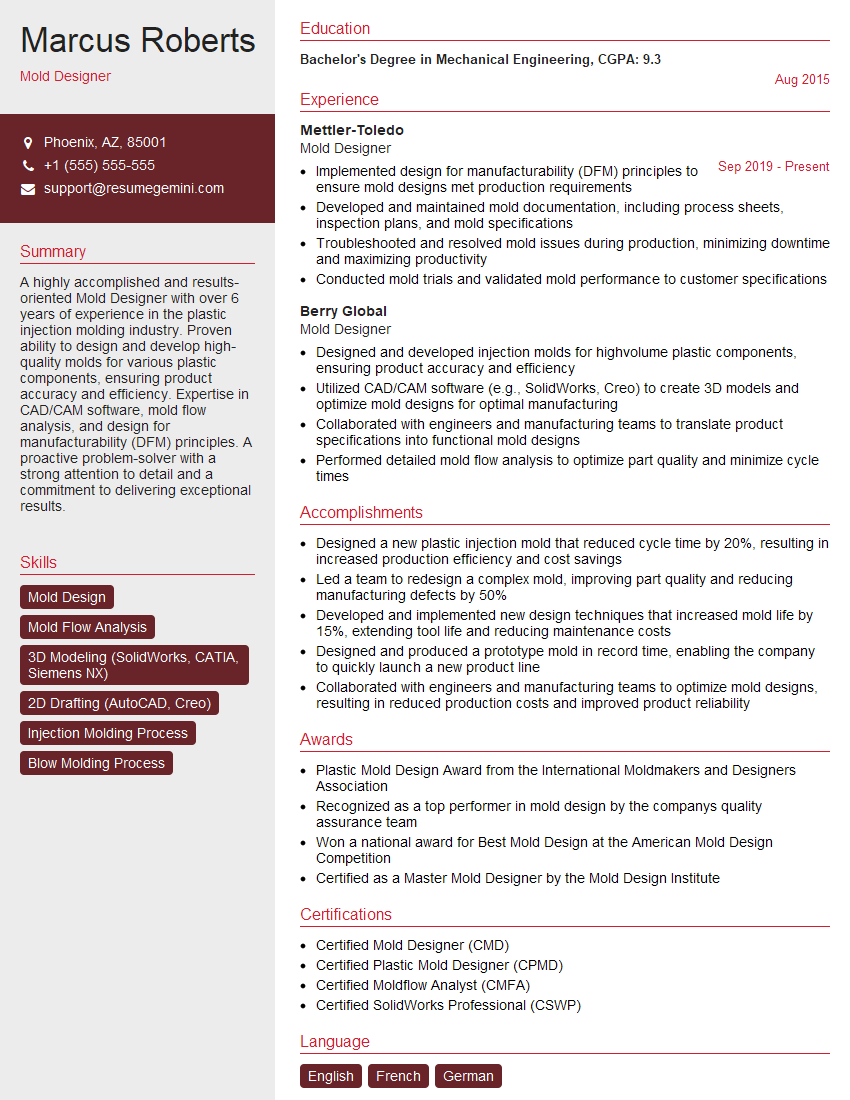

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Designer

1. What are the key factors you consider when designing a mold?

When designing a mold, I consider several key factors to ensure its functionality and efficiency:

- Part geometry: Analyzing the part’s shape, dimensions, and tolerances to determine the mold’s overall structure and cavity design.

- Material properties: Considering the material’s flow characteristics, shrinkage rates, and thermal properties to optimize the mold’s design for the specific material being molded.

- Production requirements: Understanding the desired production volume, cycle time, and quality standards to ensure the mold meets the operational targets.

- Molding process: Selecting the appropriate molding process (e.g., injection molding, blow molding, casting) and considering its specific requirements for mold design.

- Cost and manufacturability: Balancing the mold’s functionality and performance with cost considerations and ease of manufacturing.

2. Explain the different types of gating systems and when to use each type.

Types of Gating Systems

- Sprue gate: A simple and commonly used gate that connects the runner to the cavity.

- Edge gate: A gate that enters the cavity at the parting line, reducing shear stress and improving flow.

- Fan gate: A gate with multiple smaller channels that spread the melt flow evenly across the cavity.

- Pin gate: A gate that uses a pin to create a small, restricted flow path, resulting in lower shear stress.

Factors to Consider for Selecting a Gating System

- Part geometry: The shape and size of the part can influence the choice of gating system to ensure proper flow and filling.

- Material properties: Materials with high viscosity or shear sensitivity may require specific gating systems to minimize defects.

- Mold design: The location and orientation of the gating system must be compatible with the mold’s overall design.

- Production requirements: Cycle time and part quality requirements can impact the selection of a gating system that optimizes flow and minimizes cycle time.

3. What software do you use for mold design and simulation?

I am proficient in using industry-standard software for mold design and simulation:

- Computer-aided design (CAD) software: PTC Creo, SolidWorks, Autodesk Inventor

- Computer-aided engineering (CAE) software: Moldex3D, Autodesk Moldflow, Simflow

4. How do you ensure the quality of your mold designs?

I follow a rigorous process to ensure the quality of my mold designs:

- Thorough planning: Carefully reviewing customer requirements, part geometry, and production specifications.

- Detailed design: Creating detailed CAD models and considering all aspects of the mold, including gating, cooling, and ejection systems.

- Finite element analysis (FEA): Conducting FEA simulations to analyze the mold’s structural integrity, flow patterns, and potential defects.

- Design review: Collaborating with engineers and other team members to review and optimize the design.

- Prototyping and testing: Building and testing prototypes to verify the mold’s functionality and make necessary adjustments.

5. What is the importance of cooling channels in mold design?

Cooling channels play a crucial role in mold design as they:

- Control part temperature: Remove excess heat from the molded part, ensuring proper solidification and reducing the risk of defects.

- Shorten cycle time: Allow faster cooling of the part, leading to reduced production time.

- Prevent warpage: Uniform cooling helps minimize thermal stresses and prevent part warpage.

- Improve part quality: Efficient cooling promotes uniform crystallization and enhances the mechanical properties of the molded part.

6. Describe the process of ejecting a part from a mold.

The part ejection process involves:

- Ejector pin design: Selecting the appropriate type, size, and location of ejector pins to ensure proper part ejection.

- Ejection plate: Designing an ejection plate that moves the ejector pins to push the part out of the mold.

- Ejection sequence: Determining the sequence of ejector pin activation to minimize part deformation and potential damage.

- Ejection force calculation: Calculating the force required to eject the part, considering factors such as part weight and surface area.

- Ejection system maintenance: Regularly inspecting and maintaining the ejection system to ensure its reliability and prevent part ejection issues.

7. How do you optimize a mold design for low-volume production?

For low-volume production, mold design optimization involves:

- Simplification: Using simpler mold designs with fewer components to reduce manufacturing costs.

- Multi-cavity molds: Creating molds with multiple cavities to produce multiple parts simultaneously, increasing efficiency.

- Standardized components: Utilizing standard mold components to reduce design time and manufacturing complexity.

- Rapid tooling: Employing rapid prototyping or additive manufacturing techniques to reduce the lead time for mold fabrication.

- Cost-effective materials: Selecting mold materials that are cost-efficient without compromising part quality.

8. What are your experiences with designing molds for different materials?

I have experience designing molds for various materials, including:

- Plastics: Polypropylene, polyethylene, polycarbonate, ABS

- Metals: Aluminum, steel, brass

- Composites: Fiberglass, carbon fiber

- Elastomers: Silicone, rubber

9. How do you stay updated with the latest trends and advancements in mold design?

I stay updated with industry trends and advancements by:

- Attending conferences and workshops: Participating in industry events to learn about new technologies and best practices.

- Reading technical journals and publications: Reviewing industry publications to stay informed about research and developments in mold design.

- Networking with professionals: Connecting with other mold designers, engineers, and industry experts to exchange knowledge and ideas.

10. What are your strengths and weaknesses as a Mold Designer?

Strengths:

- Technical proficiency: Strong understanding of mold design principles, materials, and manufacturing processes.

- Problem-solving abilities: Excellent ability to identify and resolve design challenges, optimizing mold performance.

- Attention to detail: Meticulous in design and analysis, ensuring precision and accuracy.

- Communication skills: Effective communication with engineers, manufacturers, and clients to convey design intent and collaborate on project development.

Weaknesses:

- Experience with specific industry: Limited experience in designing molds for a particular industry (if applicable).

- Time management: Working on multiple projects simultaneously can occasionally lead to time management challenges.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Designers are highly skilled professionals who play a vital role in the manufacturing industry. They are responsible for designing and developing the molds used to produce a wide variety of products, from plastic toys to automotive parts. The key job responsibilities of a Mold Designer include:

1. Design and Develop Molds

Mold Designers use computer-aided design (CAD) software to create 3D models of molds. They must consider a variety of factors when designing a mold, including the type of product being produced, the materials being used, and the manufacturing process. Once a 3D model is complete, Mold Designers must create detailed drawings and specifications for the mold.

- Develop and design molds for various products, ensuring they meet the required specifications and quality standards.

- Analyze and interpret engineering drawings and specifications to determine mold design requirements.

2. Select Materials

Mold Designers must select the appropriate materials for the molds they design. The materials used must be able to withstand the heat and pressure of the manufacturing process. Mold Designers must also consider the cost and availability of the materials.

- Select and specify mold materials based on product requirements, manufacturing processes, and cost considerations.

- Evaluate material properties, such as strength, durability, and thermal resistance, to ensure optimal mold performance.

3. Supervise Mold Manufacturing

Mold Designers often supervise the manufacturing of the molds they design. They must ensure that the molds are manufactured according to their specifications. Mold Designers may also work with mold makers to troubleshoot any problems that arise during the manufacturing process.

- Provide technical guidance and support to mold makers during the manufacturing process.

- Inspect and approve molds prior to production to ensure they meet design specifications and quality standards.

4. Maintain Up-to-Date Knowledge

Mold Designers must keep up-to-date on the latest technologies and manufacturing processes. They must also be familiar with the latest materials and design techniques. Mold Designers can stay up-to-date by attending industry conferences and reading trade publications.

- Stay abreast of industry advancements in mold design, manufacturing techniques, and materials.

- Attend conferences, workshops, and seminars to enhance knowledge and skills.

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of making a positive impression and securing the position. Here are some tips to help you prepare for an interview as a Mold Designer.

1. Research the Company

Take the time to research the company you are interviewing with. This will help you understand the company’s culture, products, and services. You can research the company’s website, LinkedIn page, and Glassdoor reviews.

- Visit the company’s website to learn about its history, products, services, and culture.

- Read industry news and articles to stay informed about the company’s recent developments and market position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance. This will help you feel more confident and prepared during the interview.

- Prepare responses to questions about your experience, skills, and qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Be Prepared to Discuss Your Portfolio

As a Mold Designer, your portfolio is one of the most important things you can bring to an interview. Your portfolio should showcase your best work and demonstrate your skills and abilities. Be prepared to discuss your portfolio in detail and explain the design choices you made.

- Create a professional portfolio that showcases your best mold designs and projects.

- Be able to articulate the design concepts, technical specifications, and manufacturing processes involved in your projects.

4. Dress Professionally

First impressions matter. Dress professionally for your interview. This means wearing a suit or business casual attire. Make sure your clothes are clean and pressed.

- Choose attire that is appropriate for the company culture and industry.

- Pay attention to details such as polished shoes, a clean haircut, and minimal jewelry.

5. Be Confident and Enthusiastic

Confidence is key in an interview. Be confident in your abilities and your qualifications. Show the interviewer that you are excited about the opportunity to work for the company.

- Maintain eye contact, speak clearly and concisely, and demonstrate a positive attitude throughout the interview.

- Convey your passion for mold design and your eagerness to contribute to the company’s success.

Next Step:

Now that you’re armed with the knowledge of Mold Designer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold Designer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini