Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Dresser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

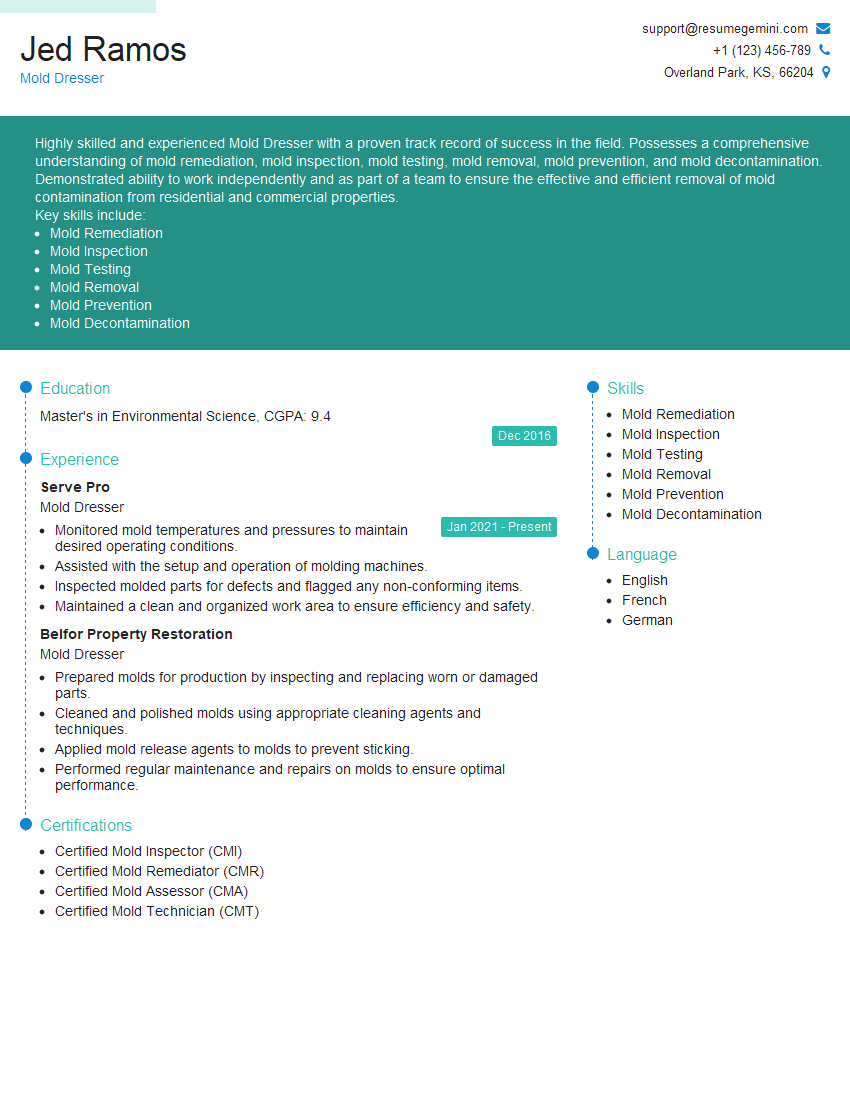

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Dresser

1. Explain the process of mold dressing?

Mold dressing involves preparing the mold surface for casting by applying a release agent and other coatings. The process typically includes the following steps:

- Cleaning the mold: Removing any dirt, debris, or previous coatings from the mold surface.

- Applying a release agent: Applying a chemical agent to the mold surface to prevent the cast material from sticking.

- Applying coatings: Applying additional coatings, such as primers or sealers, to enhance the surface finish of the cast.

- Curing: Allowing the coatings to dry and cure before using the mold for casting.

2. What types of release agents are commonly used in mold dressing?

There are different types of release agents used in mold dressing, including:

- Wax-based release agents: These agents create a physical barrier between the mold and the cast material.

- Silicone-based release agents: These agents form a thin, hydrophobic layer on the mold surface.

- Fluorinated release agents: These agents provide excellent release properties and are often used for high-temperature applications.

The choice of release agent depends on factors such as:

- The type of casting material being used

- The mold material

- The desired surface finish

3. How do you determine the appropriate thickness of coatings to apply during mold dressing?

The thickness of coatings applied during mold dressing depends on several factors:

- The type of coating being used: Different coatings have different recommended application thicknesses.

- The desired surface finish: Thicker coatings can provide a smoother finish, while thinner coatings may be sufficient for certain applications.

- The mold material: Some mold materials may require thicker coatings to ensure proper release.

It is important to follow the manufacturer’s instructions for the specific coatings being used and to adjust the thickness as needed based on experience and the desired results.

4. What are some common defects that can occur during mold dressing and how can they be prevented?

Some common defects that can occur during mold dressing include:

- Sticking: This occurs when the cast material adheres to the mold surface, resulting in a poor-quality cast.

- Blisters: These are air bubbles trapped in the cast material, which can weaken the cast.

- Cracks: These can occur due to improper curing of the coatings or excessive force applied during casting.

To prevent these defects:

- Ensure that the mold surface is clean and free of any contaminants.

- Apply the release agent and coatings evenly and according to the manufacturer’s instructions.

- Allow the coatings to cure properly before using the mold for casting.

- Use the correct casting technique and avoid applying excessive force.

5. How do you maintain and store molds after dressing?

Proper maintenance and storage of molds after dressing are crucial to ensure their longevity and performance:

- Cleaning: After each use, clean the mold thoroughly to remove any residual casting material or coatings.

- Inspection: Regularly inspect the mold for any damage or defects, such as cracks or wear on the mold surface.

- Re-dressing: If the mold surface shows signs of wear or damage, re-dress the mold by applying a new release agent and coatings.

- Storage: Store molds in a clean, dry place away from direct sunlight or extreme temperatures.

6. What are the safety precautions that should be taken when working with mold dressing materials?

Mold dressing materials, such as release agents and coatings, can contain hazardous chemicals:

- Wear appropriate personal protective equipment (PPE): This includes gloves, eye protection, and a respirator if necessary.

- Ensure proper ventilation: Work in a well-ventilated area or use a fume hood.

- Avoid skin contact: Wear gloves and avoid touching the mold dressing materials with bare hands.

- Follow manufacturer’s instructions: Carefully read and follow the instructions provided by the manufacturer of the mold dressing materials.

7. How do you troubleshoot common problems that may arise during mold dressing?

Troubleshooting common problems in mold dressing requires a systematic approach:

- Sticking: Check if the mold surface is clean and free of contaminants, and if the release agent has been applied evenly and according to the manufacturer’s instructions.

- Blisters: Ensure that the mold and coatings are dry before casting, and adjust the casting technique to avoid trapping air bubbles.

- Cracks: Inspect the mold for any damage or defects, and ensure that the coatings have been applied correctly and allowed to cure properly.

8. What are the latest advancements or innovations in mold dressing techniques?

The field of mold dressing is constantly evolving, with new techniques and materials being developed:

- Advanced release agents: New release agents with improved release properties, such as nano-based release agents, are being developed to enhance casting efficiency.

- Automated mold dressing systems: Automated systems can improve the consistency and efficiency of mold dressing, reducing the risk of human error.

- Environmentally friendly mold dressing materials: Sustainable and environmentally friendly mold dressing materials are being developed to minimize the environmental impact of the process.

9. How do you stay updated with the latest developments and best practices in mold dressing?

Keeping up with the latest developments and best practices in mold dressing is essential for continuous improvement:

- Attend industry events and conferences: These events provide opportunities to learn about new technologies and network with experts.

- Read technical publications and journals: Industry publications and journals provide valuable information on advancements and best practices.

- Connect with manufacturers and suppliers: Manufacturers and suppliers can provide information on the latest products and techniques.

10. What is your approach to ensuring the quality of mold dressing operations?

Quality assurance in mold dressing involves implementing systematic procedures and monitoring processes:

- Establishing quality standards: Define clear quality standards for the mold dressing process and cast products.

- Regular inspections: Conduct regular inspections of molds, equipment, and materials to ensure they meet quality standards.

- Documentation: Maintain detailed records of mold dressing operations, including materials used, techniques employed, and any quality issues encountered.

- Continuous improvement: Regularly review and improve mold dressing processes to enhance efficiency and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Dresser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Dresser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Dressers are highly skilled professionals responsible for preparing and maintaining molds for various manufacturing processes, particularly in the automotive, plastic, and metalworking industries. Their primary objective is to ensure the molds operate effectively and produce high-quality products.

1. Mold Preparation and Maintenance

Preparing new molds involves cleaning, inspecting, and applying protective coatings to ensure they are in optimal condition for use. Maintaining existing molds requires thorough cleaning, repairing any defects, and replacing worn or damaged components.

- Inspect new molds for any defects or damage before use.

- Clean molds thoroughly to remove any debris, contaminants, or rust.

- Apply protective coatings to molds to prevent corrosion and extend their lifespan.

- Repair minor mold defects, such as scratches or dents, to ensure optimal performance.

- Replace worn or damaged mold components, such as pins, bushings, or slides.

2. Mold Alignment and Setup

Mold Dressers play a crucial role in aligning and setting up molds on various manufacturing equipment. They ensure proper alignment between the mold and the machine, ensuring precise and efficient production.

- Align molds correctly on molding machines, using precision measuring tools and techniques.

- Secure molds firmly in place to prevent movement during operation.

- Adjust mold settings, such as temperature and pressure, to optimize production efficiency.

- Monitor mold performance during production to identify and address any issues promptly.

- Troubleshoot and resolve mold-related problems, such as misalignment, flashing, or excessive wear.

3. Mold Documentation and Record-Keeping

Accurate documentation of mold maintenance and repairs is essential for quality control and historical tracking purposes. Mold Dressers maintain detailed records of all work performed on molds, including repairs, replacements, and adjustments.

- Document all mold maintenance and repair activities, including dates, materials used, and actions taken.

- Maintain inventory of mold components, including spare parts and consumables.

- Prepare reports on mold performance and identify areas for improvement.

- Collaborate with engineers and other technicians to optimize mold design and production processes.

- Stay updated on industry best practices and advancements related to mold dressing techniques.

4. Safety Compliance and Training

Mold Dressers must adhere to strict safety protocols to prevent accidents and injuries in the workplace. They receive regular training on safety procedures and proper use of tools and equipment.

- Follow all safety regulations and wear appropriate personal protective equipment (PPE).

- Operate machinery safely and use tools correctly to avoid hazards.

- Maintain a clean and organized work area to prevent tripping or other incidents.

- Report any safety concerns or potential hazards to supervisors immediately.

- Participate in regular safety training programs to stay informed of industry best practices.

Interview Tips

Preparing thoroughly for your interview is crucial to increasing your chances of success. Here are some tips and tricks to help you ace your Mold Dresser interview.

1. Research the Company and Position

Take the time to research the company you’re applying to, including their industry, products or services, and company culture. Understanding the company’s needs and values will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay informed about the latest trends and challenges.

- Look for any recent press releases or announcements from the company to demonstrate your interest.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in Mold Dresser interviews. By practicing your answers to these questions, you can become more confident and articulate during the actual interview.

- Tell me about your experience in mold dressing and repair.

- Describe a time when you had to troubleshoot a complex mold issue.

- What are your strengths and weaknesses as a Mold Dresser?

3. Highlight Your Relevant Skills and Experience

During the interview, emphasize your skills and experience that are most relevant to the job requirements. Use specific examples to demonstrate your abilities and how they have benefited previous employers.

- Highlight your expertise in mold preparation, alignment, and setup.

- Provide examples of how you have successfully repaired or maintained molds, resulting in improved production efficiency.

- Mention your knowledge of different types of molds and the materials used in their construction.

4. Show Your Passion and Dedication

Express your passion and dedication to the field of mold dressing. Share any specific interests or projects you have undertaken that demonstrate your commitment to the craft.

- Discuss your interest in mold design and innovation.

- Mention any industry seminars or conferences you have attended to enhance your knowledge.

- Share your willingness to go the extra mile to ensure the molds are performing at their best.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. It also gives you an opportunity to clarify any details about the role or the organization.

- Ask about the company’s future plans and growth opportunities.

- Inquire about the specific challenges or projects you may encounter in the role.

- Ask about the company’s commitment to safety and training.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold Dresser role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.