Feeling lost in a sea of interview questions? Landed that dream interview for Mold Filler and Drainer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold Filler and Drainer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

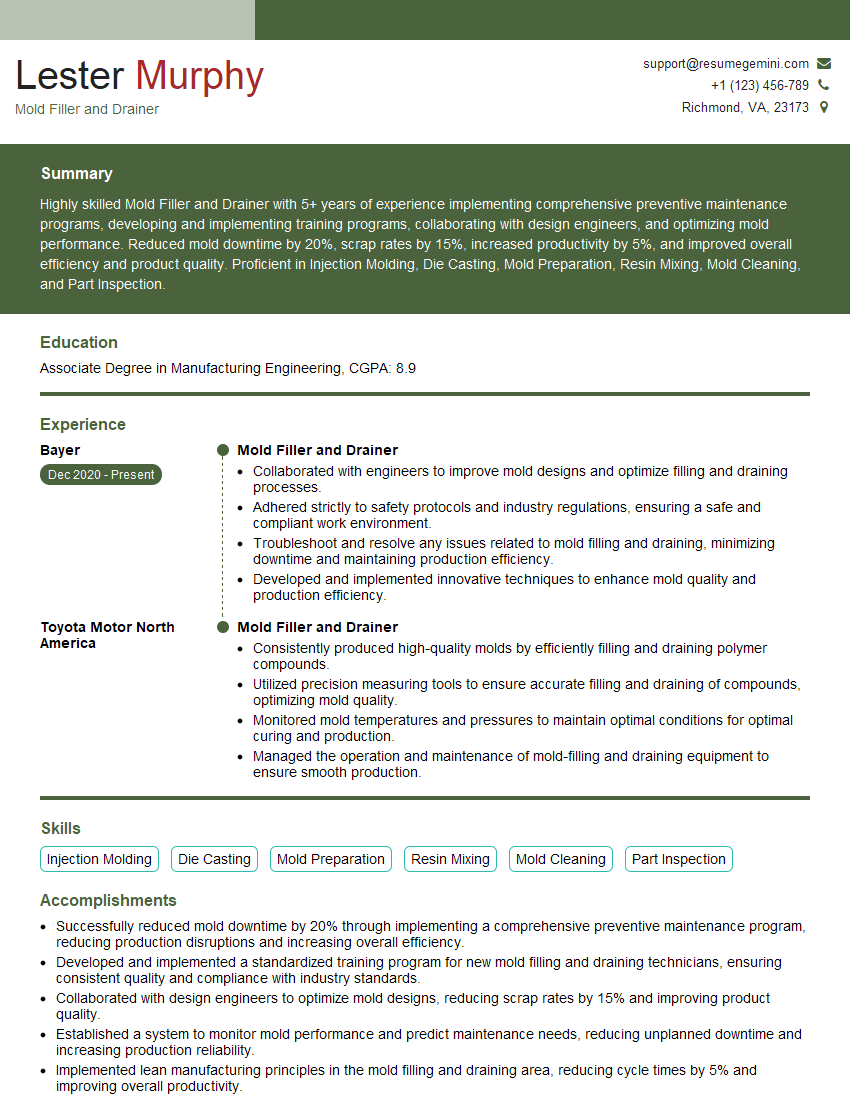

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Filler and Drainer

1. How do you ensure the accuracy of filling and draining operations?

To ensure accuracy, I follow these steps:

- Calibrate Equipment Regularly: I regularly calibrate the filling and draining equipment according to the manufacturer’s specifications.

- Verify Measurements: Before filling or draining, I double-check all measurements using appropriate measuring devices or scales.

- Follow Standard Procedures: I strictly adhere to established filling and draining procedures that outline the precise steps and parameters.

2. Describe the safety precautions you take when handling hazardous materials during filling and draining processes.

To ensure safety when handling hazardous materials, I take the following precautions:

Proper Personal Protective Equipment (PPE):

- Wear appropriate gloves, goggles, and respirators to protect myself from contact, inhalation, and splash hazards.

- Use spill kits and containment measures to prevent spills and control any potential leaks.

Safe Handling Techniques:

- Follow designated handling procedures, such as lifting techniques and proper waste disposal.

- Avoid skin contact with hazardous materials and thoroughly wash my hands and clothing after handling.

Emergency Preparedness:

- Familiarize myself with the Material Safety Data Sheet (MSDS) for each hazardous material.

- Know the location of safety showers and eye wash stations in case of an incident.

3. How do you handle unexpected spills or leaks during filling and draining operations?

When encountering spills or leaks during filling or draining operations, I prioritize safety and follow these steps:

- Contain the Spill: Use spill kits, absorbent materials, or other appropriate measures to contain and control the spill.

- Isolate the Area: Restrict access to the affected area to prevent further accidents or contamination.

- Notify Supervisor: Inform the supervisor immediately to report the incident and seek guidance on further actions.

- Clean Up Safely: Follow proper cleanup procedures, using appropriate cleaning agents and personal protective equipment.

- Document the Incident: Record the incident details, including the type of material spilled, quantity, location, and cleanup measures taken.

4. Explain how you maintain and troubleshoot filling and draining equipment to ensure optimal performance.

To maintain and troubleshoot filling and draining equipment, I perform the following tasks:

- Regular Maintenance: Conduct routine inspections, cleaning, and lubrication of equipment according to manufacturer’s guidelines.

- Troubleshooting: Diagnose and resolve equipment malfunctions by identifying the root cause and applying appropriate repair techniques.

- Preventive Maintenance: Anticipate potential issues by identifying wear and tear, loose connections, or other signs of deterioration.

- Equipment Calibration: Ensure accuracy and precision by calibrating equipment as per established specifications.

- Training: Stay updated on new equipment technologies and best practices through manufacturer training or industry resources.

5. How do you ensure the cleanliness and hygiene of filling and draining equipment to prevent contamination?

To maintain cleanliness and hygiene of filling and draining equipment, I follow these practices:

- Regular Cleaning: Thoroughly clean all equipment after each use with appropriate detergents and disinfectants.

- Sanitization: Use approved sanitizing agents to eliminate any microorganisms that could contaminate the product.

- Inspection: Inspect equipment for cleanliness before and after each operation to ensure it meets hygiene standards.

- Preventive Measures: Implement preventive measures, such as using covers or seals, to protect equipment from dust and other contaminants.

6. How do you optimize filling and draining processes to increase efficiency and productivity?

To optimize filling and draining processes, I focus on these areas:

- Process Analysis: Identify bottlenecks and areas for improvement through process mapping and time studies.

- Equipment Upgrades: Explore new equipment technologies that can enhance speed, accuracy, and reliability.

- Workflow Optimization: Streamline workflow by reducing unnecessary steps, improving communication, and eliminating duplicate tasks.

- Training: Provide training to operators to ensure proper equipment operation and efficient work practices.

7. What is your experience in operating and maintaining automated filling and draining systems?

In my previous role, I was responsible for the operation and maintenance of a fully automated filling and draining system, including the following tasks:

- System Monitoring: Monitored and adjusted system parameters, ensuring smooth operation and product quality.

- Troubleshooting: Diagnosed and resolved system malfunctions using diagnostic tools and manufacturer’s guidelines.

- Preventive Maintenance: Conducted regular maintenance and calibration to prevent breakdowns and ensure system longevity.

- Process Optimization: Collaborated with engineers to identify areas for improvement and enhance the overall efficiency of the system.

8. How do you stay updated with the latest advancements in filling and draining technologies?

To stay updated with the latest advancements in filling and draining technologies, I engage in the following activities:

- Industry Conferences: Attend industry conferences and trade shows to learn about new technologies and best practices.

- Technical Literature: Read technical journals, articles, and case studies to enhance my knowledge and skills.

- Online Resources: Utilize online resources, such as manufacturer websites and industry blogs, to stay abreast of technological innovations.

- Equipment Training: Participate in training sessions and webinars offered by equipment manufacturers to gain hands-on experience with new technologies.

9. What is your understanding of GMP guidelines for filling and draining operations in the pharmaceutical industry?

GMP (Good Manufacturing Practices) guidelines are crucial in ensuring the safety and quality of pharmaceutical products. My understanding of GMP guidelines for filling and draining operations includes:

- Process Validation: Validate filling and draining processes to demonstrate compliance with GMP requirements.

- Equipment Qualification: Qualify equipment used in filling and draining operations to ensure it meets GMP specifications.

- Environmental Control: Maintain appropriate environmental conditions, such as temperature and humidity, to prevent product contamination.

- Personnel Training: Train personnel on GMP guidelines and proper filling and draining procedures.

- Documentation: Maintain accurate and complete documentation of all filling and draining operations, including batch records and quality control data.

10. How do you handle and resolve quality control issues related to filling and draining operations?

When quality control issues arise during filling and draining operations, I take the following steps:

- Identify the Issue: Determine the root cause of the quality control issue through investigation and data analysis.

- Implement Corrective Actions: Develop and implement corrective actions to address the issue and prevent its recurrence.

- Document the Findings: Document the investigation findings, corrective actions taken, and any necessary changes to standard operating procedures.

- Follow Up: Monitor the effectiveness of corrective actions and make further adjustments as needed to ensure the issue is fully resolved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Filler and Drainer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Filler and Drainer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Fillers and Drainers are responsible for maintaining the production line by preparing molds for casting and removing finished products. They ensure that molds are properly filled with molten metal and that finished castings are drained of excess metal. Their key responsibilities include:

1. Mold Preparation

inspecting molds for defects, cleaning and lubricating molds, and applying release agents to prevent castings from sticking.

2. Filling Molds

operating pouring equipment to fill molds with molten metal, controlling the flow of metal to ensure proper filling, and monitoring temperature to prevent premature solidification.

3. Draining Molds

draining excess molten metal from castings using a variety of techniques such as tilting, inverting, or using a vacuum system, and ensuring that castings are completely drained of excess metal.

4. Quality Control

inspecting castings for defects such as cracks, voids, or inclusions, and reporting any issues to supervisors, and maintaining records of casting production and quality.

5. Equipment Maintenance

cleaning and maintaining mold filling and draining equipment, including pouring ladles, funnels, and vacuum systems.

6. Safety

adhering to safety protocols, wearing appropriate protective gear, and operating equipment in a safe manner.

Interview Tips

Preparing for an interview for a Mold Filler and Drainer position requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s website and social media pages to understand their business and industry. Research the specific position you’re applying for and identify the key responsibilities and qualifications.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers beforehand. Practice delivering your responses clearly and concisely, highlighting your relevant skills and experience.

3. Demonstrate Your Technical Skills

Emphasize your knowledge of mold filling and draining techniques, as well as your experience in operating and maintaining equipment. Share specific examples of your work and how you have contributed to production efficiency.

4. Highlight Your Quality Control Procedures

Explain your understanding of quality control standards and your ability to inspect castings for defects. Provide examples of how you have identified and resolved quality issues.

5. Show Your Safety Consciousness

Emphasize your commitment to safety and your understanding of the potential hazards involved in the role. Describe your experience with safety protocols and your ability to work in a safe environment.

6. Be Enthusiastic and Engaged

Throughout the interview, maintain a positive and enthusiastic demeanor. Show your genuine interest in the role and the company, and ask thoughtful questions to demonstrate your engagement.

7. Follow Up

After the interview, send a thank-you note to the interviewer, reiterating your interest in the position and summarizing your key qualifications. Inquire about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Filler and Drainer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.