Are you gearing up for a career in Mold Injector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mold Injector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

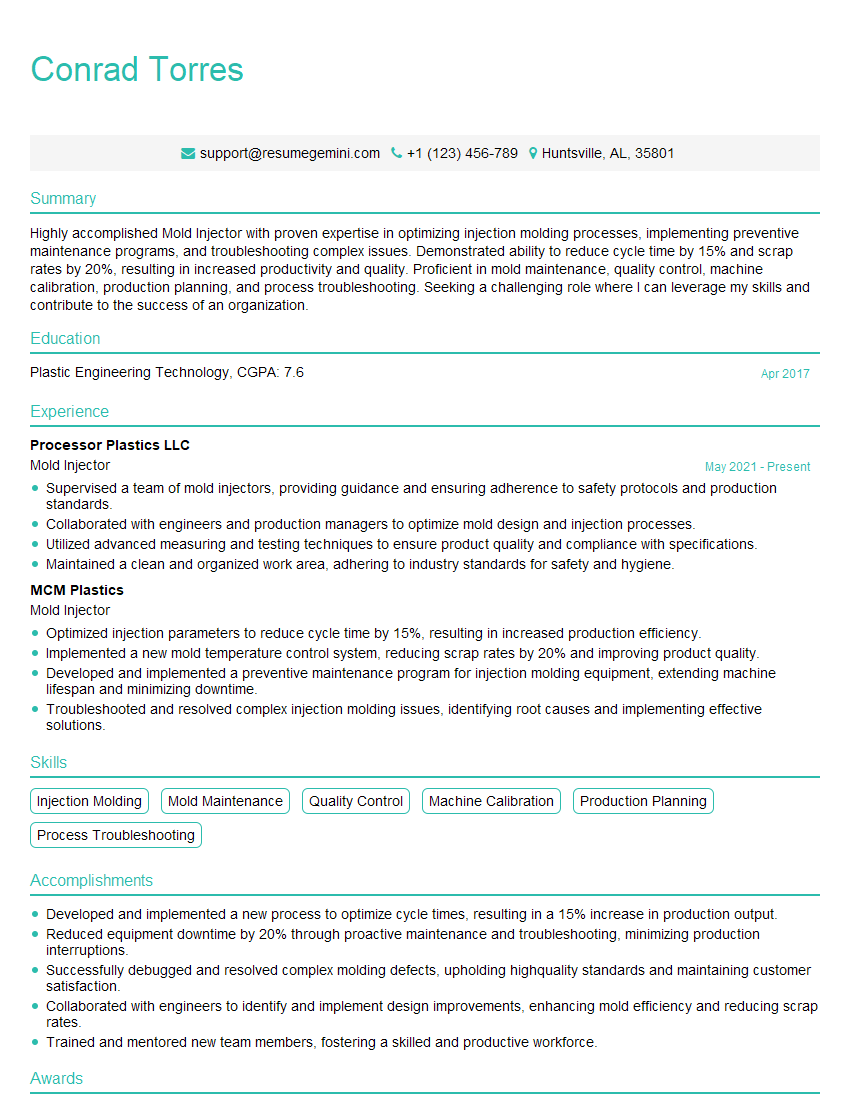

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Injector

1. Describe the injection molding process and the role of a Mold Injector.

The injection molding process is a manufacturing technique used to produce plastic parts. It involves injecting molten plastic into a mold cavity, where it cools and solidifies to form the desired shape. The Mold Injector is responsible for operating the injection molding machine and ensuring that the plastic is injected into the mold correctly.

2. What are the different types of injection molding machines?

Hydraulic Injection Molding Machines

- Hydraulic power is used to move the mold.

- Used in low-volume production.

Electric Injection Molding Machines

- Electric motors are used to move the mold.

- More precise and energy-efficient.

Hybrid Injection Molding Machines

- Combine hydraulic and electric power.

- Offer a balance of precision and efficiency.

3. What are the key factors to consider when selecting an injection molding machine?

- Clamping force: Determines the size of parts that can be produced.

- Injection pressure: Affects the quality and precision of parts.

- Cycle time: Determines the production rate.

- Material compatibility: Ensures the machine can handle the materials used.

4. What are the common defects that can occur in injection molding?

- Short shots: Incomplete filling of the mold.

- Flash: Excess material that escapes the mold.

- Sink marks: Depressions in the part caused by uneven cooling.

- Warpage: Distortion of the part after molding.

5. How do you troubleshoot injection molding defects?

- Inspect the mold for any damage or contamination.

- Check the injection pressure and temperature.

- Adjust the mold temperature or cooling time.

- Experiment with different materials or additives.

6. What are the safety precautions to observe when operating an injection molding machine?

- Wear appropriate protective gear.

- Keep the work area clean and free of hazards.

- Follow lockout/tagout procedures.

- Be aware of potential hazards such as hot surfaces and molten plastic.

7. What are the maintenance procedures for an injection molding machine?

- Regularly clean and lubricate the machine.

- Inspect and replace worn or damaged parts.

- Perform preventive maintenance tasks as recommended by the manufacturer.

- Calibrate the machine regularly to ensure accuracy.

8. What are the emerging trends in injection molding technology?

- Automation and robotics:

- Additive manufacturing:

- Sustainable practices:

9. How do you stay updated with the latest advancements in injection molding?

- Attend industry conferences and exhibitions.

- Read trade magazines and technical journals.

- Participate in online forums and discussions.

- Seek training and certification opportunities.

10. Can you describe a challenging injection molding project you have worked on and how you overcame the challenges?

In my previous role, I was involved in a project to produce a complex medical device with tight tolerances and high-quality requirements. One of the challenges we faced was achieving the required surface finish. We experimented with different materials, injection pressures, and mold temperatures until we found the optimal combination that met the specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Injector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Injector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Injectors play a critical role in the manufacturing process, and their responsibilities are essential for maintaining production efficiency and product quality.

1. Mold Setup and Operation

Mold Injectors set up and operate injection molding machines to produce plastic or rubber parts. They ensure that the molds are properly installed and that the injection molding parameters, such as temperature, pressure, and cycle time, are optimized for the specific material and product being produced.

- Adjusting molding parameters to optimize production efficiency and product quality

- Identifying and resolving mold malfunctions, such as blocked nozzles or leaks

- Ensuring that molds are properly maintained and cleaned to prevent contamination and extend their lifespan

2. Quality Control

Mold Injectors conduct quality control checks on the molded parts to ensure that they meet the required specifications, including dimensional accuracy, surface finish, and mechanical properties.

- Performing visual inspections and using measuring instruments to assess part quality

- Identifying and rejecting non-conforming parts, such as those with defects or imperfections

- Maintaining documentation and records of quality control checks

3. Safety and Maintenance

Mold Injectors prioritize safety in the workplace and maintain a clean and organized work area to prevent accidents or injuries.

- Following safety protocols and wearing proper protective gear

- Performing routine maintenance on injection molding machines and molds to ensure optimal performance

- Maintaining a clean and organized work area to minimize risks and improve efficiency

4. Troubleshooting and Problem-Solving

Mold Injectors possess the ability to troubleshoot and resolve problems that may arise during the injection molding process.

- Identifying the root cause of production issues, such as part defects, machine breakdowns, or material inconsistencies

- Implementing corrective actions to resolve problems and minimize downtime

- Documenting and communicating problem-solving solutions to improve future operations

Interview Tips

To ace the interview for a Mold Injector position, it is important to prepare thoroughly and highlight your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to learn about the company, its products, and the specific responsibilities of the Mold Injector role. This will demonstrate your interest in the position and show that you have a basic understanding of the industry and the company’s operations.

2. Highlight Your Relevant Skills and Experience

During the interview, emphasize your key skills and experience that directly relate to the job requirements. For example, showcase your expertise in mold setup and operation, quality control procedures, and troubleshooting. Quantify your achievements whenever possible to provide tangible evidence of your abilities.

3. Prepare Examples of Problem-Solving and Decision-Making

Interviewers often ask candidates to provide examples of how they have handled challenges or made decisions in previous roles. Prepare a few specific examples that demonstrate your problem-solving abilities, critical thinking skills, and decision-making capabilities. These examples should highlight your ability to identify issues, evaluate options, and implement effective solutions.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows the interviewer that you are engaged and interested in the position. This is an excellent opportunity to clarify any details about the role, the company culture, or the industry. Asking intelligent questions also demonstrates your eagerness to learn and your commitment to professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Injector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!