Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Insert Changer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

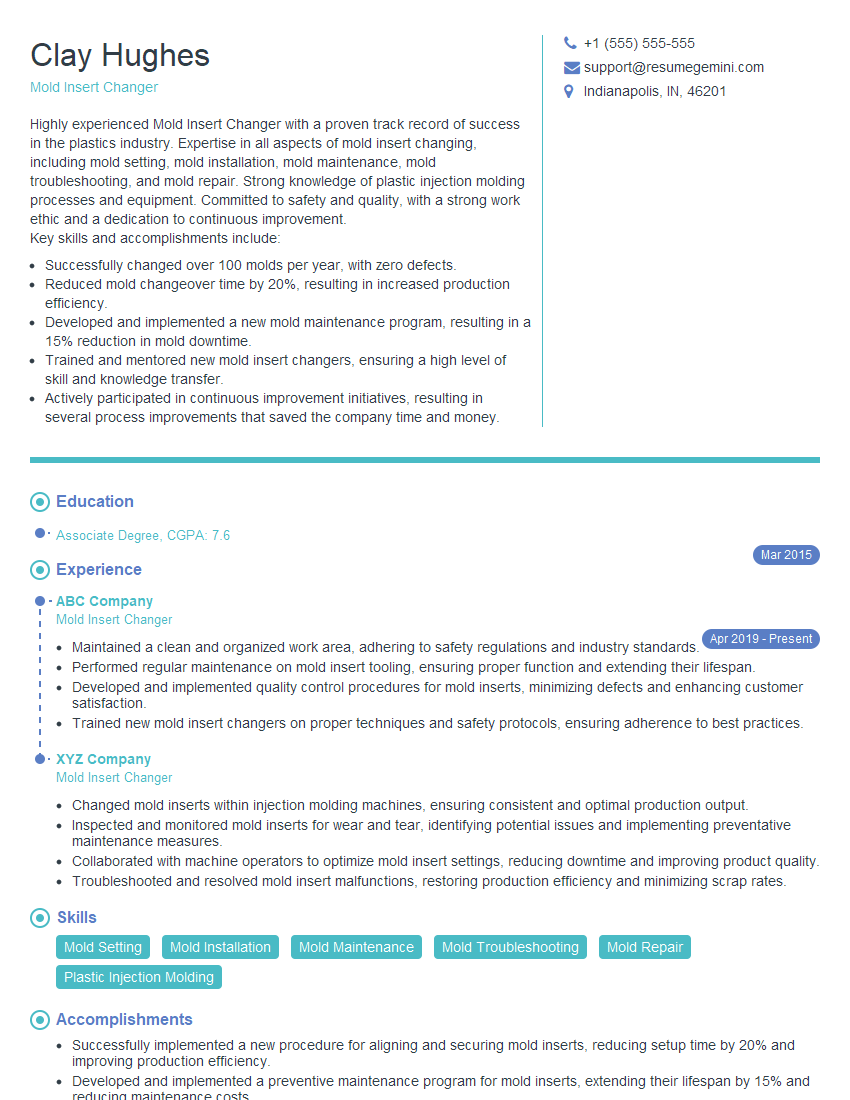

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Insert Changer

1. Describe the process of changing a mold insert in a machine.

The process of changing a mold insert in a machine involves several steps to ensure proper installation and operation:

- Safety Precautions: Wear appropriate personal protective equipment (PPE) and follow safety protocols.

- Machine Preparation: Ensure that the machine is properly isolated from power and other utilities, and that the movable components are locked out or restrained.

- Insert Removal: Using appropriate tools, carefully remove the existing mold insert from the machine.

- Insert Inspection: Inspect the removed insert for any damage or wear. Report any issues to the supervisor.

- New Insert Preparation: Inspect the new mold insert, ensuring that it is the correct one and that it is in good condition.

- Insert Installation: Carefully align and position the new mold insert into the machine, using proper tools and techniques.

- Secure Insert: Tighten bolts or clamps to secure the mold insert firmly in place.

- Machine Setup: Adjust machine settings and parameters to accommodate the new mold insert, including alignment, temperature, and pressure.

- Testing: Perform a test run to verify the proper operation of the machine with the new mold insert.

2. What are the different types of mold inserts and their applications?

Hot Runner Inserts

- Maintain temperature control of molten plastic, allowing for faster cycle times and reduced waste.

- Used in complex molding applications with multiple gates and high-precision parts.

Core Inserts

- Create internal features and cavities in molded parts.

- Can be used for forming holes, threads, and other geometric shapes.

Cavity Inserts

- Form the external shape of molded parts.

- Must be precisely machined to ensure dimensional accuracy and surface finish.

Slide Inserts

- Provide movable features within the mold, allowing for undercuts or complex geometries.

- Controlled by hydraulic or pneumatic systems to achieve specific part shapes.

3. What are the common materials used for mold inserts and their properties?

- Tool Steels: Hardened steels with high wear resistance and dimensional stability (e.g., H13, D2).

- Stainless Steels: Corrosion-resistant and easy to maintain (e.g., 303, 420).

- Beryllium Copper: High thermal conductivity and electrical conductivity, suitable for hot runner systems.

- Aluminum Alloys: Lightweight and corrosion-resistant, used in low-pressure casting.

- Carbide: Extremely hard and wear-resistant, used for inserts with intricate geometries.

4. What factors affect the life expectancy of mold inserts?

- Material properties and wear resistance.

- Mold design and geometry (e.g., sharp corners, high-pressure areas).

- Injection molding process parameters (e.g., temperature, pressure, cycle time).

- Maintenance and lubrication practices.

- External factors such as environmental conditions and chemical exposure.

5. Describe the safety protocols for working with mold inserts.

- Wear appropriate PPE, including gloves, safety glasses, and protective clothing.

- Follow proper lockout/tagout procedures to prevent accidental machine activation.

- Use sharp tools with caution and always cut away from the body.

- Be aware of potential pinch points and moving parts.

- Handle mold inserts with care to avoid damage or injury.

6. How do you troubleshoot common problems with mold inserts?

- Plastic Sticking to Inserts: Check surface finish, temperature settings, and lubrication.

- Insert Wear: Inspect for excessive wear or damage, consider using more wear-resistant materials or optimizing process parameters.

- Alignment Issues: Verify proper mold setup and insert positioning, adjust alignment as necessary.

- Flash Formation: Examine cavity and core inserts for signs of wear or misalignment, adjust clamping force or modify mold design.

- Cracked or Damaged Inserts: Immediately stop operation and inspect inserts. Determine the cause and replace or repair damaged components.

7. What are the key performance indicators (KPIs) for mold insert changers?

- Changeover time (time taken to replace an insert).

- Insert life expectancy (number of cycles before insert replacement).

- Machine uptime (percentage of time machine is operational).

- Mold insert quality (freedom from defects and dimensional accuracy).

- Production output (number of parts produced per shift or day).

8. How can you improve the efficiency of mold insert changing operations?

- Standardize Processes: Establish clear procedures and checklists to ensure consistent execution.

- Optimize Tooling: Use specialized tools and equipment designed for efficient insert changing.

- Preventive Maintenance: Regularly inspect and maintain mold inserts and machines to prevent failures.

- Training: Provide comprehensive training to employees on insert changing techniques and safety protocols.

- Collaboration: Work closely with mold designers and engineers to optimize insert design and performance.

9. What are the latest technologies or advancements in mold insert changing?

- Automated Insert Changers: Robotic systems that can automatically remove and install mold inserts.

- Virtual Reality (VR) Training: Immersive simulations that train employees on insert changing procedures.

- Sensors and IoT: Monitor insert performance and predict maintenance needs.

- Additive Manufacturing (3D Printing): Create custom mold inserts with complex geometries.

- Advanced Materials: Development of new materials with improved wear resistance and thermal conductivity.

10. What is your approach to continuous improvement and innovation in mold insert changing operations?

- Regularly evaluate current practices and identify areas for improvement.

- Research and explore new technologies and advancements.

- Implement pilot programs to test and validate improvements.

- Seek feedback from employees and stakeholders.

- Continuously monitor results and adjust the improvement process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Insert Changer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Insert Changer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold insert changers are responsible for the safe and efficient changeover of molds in a manufacturing environment. Their key responsibilities include:1. Mold Changeovers

Mold insert changers are responsible for the safe and efficient changeover of molds in a manufacturing environment. This involves:

- Preparing the machine for mold changeover

- Removing the existing mold

- Installing the new mold

- Aligning and leveling the mold

- Tightening and securing the mold

- Connecting the mold to the machine’s hydraulic and electrical systems

- Testing the mold to ensure it is functioning properly

2. Mold Maintenance

Mold insert changers are also responsible for the maintenance of molds. This involves:

- Cleaning and inspecting molds

- Lubricating molds

- Replacing worn or damaged mold components

- Storing molds in a safe and dry environment

3. Quality Control

Mold insert changers are responsible for monitoring the quality of the products being produced. This involves:

- Inspecting products for defects

- Rejecting defective products

- Reporting quality issues to the supervisor

4. Safety

Mold insert changers are responsible for working in a safe manner. This involves:

- Following all safety procedures

- Wearing appropriate safety gear

- Using proper lifting techniques

- Reporting any safety hazards to the supervisor

Interview Tips

To ace your interview for a mold insert changer position, it is important to be prepared to answer questions about your experience and qualifications. Here are some interview tips to help you prepare:1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight your experience and qualifications

In your interview, be sure to highlight your experience and qualifications that are relevant to the position you are applying for. For example, if you have experience in mold changeovers, be sure to mention this in your answer to the question “Tell me about your experience”.

4. Dress professionally and arrive on time

First impressions matter, so be sure to dress professionally and arrive on time for your interview. This will show the interviewer that you are taking the interview seriously and that you are a reliable candidate.

5. Be confident and enthusiastic

Confidence and enthusiasm are two important traits that interviewers look for in candidates. Be sure to project a positive attitude and demonstrate your passion for the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Insert Changer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!