Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Laminator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

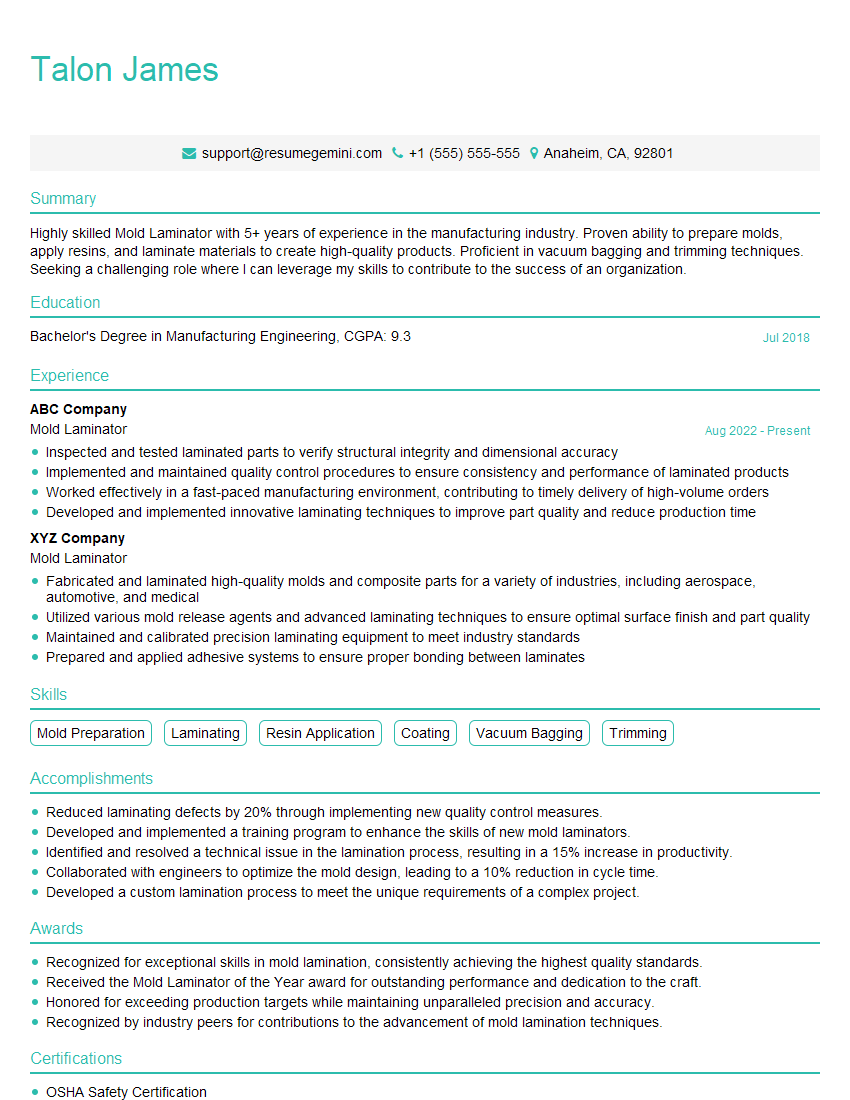

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Laminator

1. Describe the steps involved in the mold laminating process.

The mold laminating process involves several steps:

- Mold preparation: Cleaning, inspecting, and preparing the mold surface for lamination.

- Laminate preparation: Cutting and sizing the laminate material to fit the mold.

- Adhesive application: Applying an appropriate adhesive to the back of the laminate.

- Laminate placement: Carefully placing the laminate onto the mold, aligning it precisely.

- Vacuum bagging: Covering the laminate with a vacuum bag and applying vacuum to remove air and create pressure.

- Curing: Heating or exposing the laminated mold to initiate the adhesive bonding process.

- Demolding: Removing the cured laminate from the mold.

- Finishing: Trimming, sanding, or polishing the laminate surface as needed.

2. How do you ensure the proper alignment and positioning of the laminate on the mold?

To ensure proper alignment, I employ several techniques:

- Reference points: Using marks or features on the mold as reference points for laminate placement.

- Alignment tools: Utilizing alignment tools such as gauges, pins, or templates to guide the laminate.

- Vacuum hold: Employing a vacuum bagging system to create a tight adhesion between the mold and laminate, ensuring it remains in place.

- Visual inspection: Carefully inspecting the laminate alignment before and during the vacuum bagging process.

3. What types of adhesives are commonly used in mold laminating and how do you select the appropriate one?

Commonly used adhesives include:

- Epoxy adhesives: Strong, high-temperature resistant, and suitable for various substrates.

- Polyester adhesives: Fast-curing, cost-effective, and ideal for fiberglass and GRP laminates.

- Acrylic adhesives: Transparent, flexible, and provide good initial adhesion.

- Phenolic adhesives: Durable, heat-resistant, and suitable for metal and wood laminates.

I select the appropriate adhesive based on factors such as the substrate materials, bonding requirements, and environmental conditions.

4. How do you control the vacuum pressure during the vacuum bagging process and why is it important?

Vacuum pressure is crucial because it removes air pockets, ensures laminate adhesion, and reduces defects.

I control vacuum pressure using a vacuum pump and gauge:

- Initial vacuum: Apply a lower vacuum initially to avoid distorting the laminate.

- Progressive increase: Gradually increase the vacuum to the recommended level for the adhesive.

- Monitoring and adjustment: Monitor the vacuum gauge and adjust the pump settings as necessary to maintain the desired pressure.

5. What is the purpose of curing in mold laminating and how do you monitor the curing process?

Curing is the process of initiating the chemical reaction that bonds the laminate to the mold.

I monitor the curing process by:

- Temperature monitoring: Using thermocouples or temperature sensors to track the temperature of the mold or laminate.

- Time monitoring: Following the adhesive manufacturer’s recommended curing time and temperature.

- Visual inspection: Observing the laminate for signs of curing, such as hardening or color change.

6. Describe the common defects that can occur in mold laminating and how to prevent them.

Common defects include:

- Air pockets: Caused by inadequate vacuum pressure or improper laminate alignment.

- Delamination: Occurs when the adhesive fails to bond properly, often due to improper surface preparation.

- Warping: Excessive heat or vacuum pressure can cause the laminate to warp.

- Surface imperfections: Contamination, scratches, or poor finishing techniques.

Prevention measures include:

- Ensuring proper vacuum pressure and laminate alignment.

- Thoroughly cleaning and preparing the mold and laminate surfaces.

- Controlled heating and vacuum during curing.

- Careful handling and finishing techniques.

7. How do you maintain and calibrate the equipment used in mold laminating?

Equipment maintenance and calibration are crucial for accurate and consistent results.

I follow these practices:

- Regular cleaning: Cleaning vacuum pumps, gauges, and temperature sensors regularly.

- Calibration: Calibrating vacuum gauges and temperature sensors using traceable standards.

- Preventive maintenance: Performing routine inspections and maintenance on equipment to prevent breakdowns.

- Adherence to manufacturer’s guidelines: Following the equipment manufacturer’s instructions for maintenance and calibration.

8. What are the safety precautions that you observe during mold laminating?

Safety is paramount in mold laminating.

I adhere to precautions such as:

- Personal protective equipment: Wearing gloves, safety glasses, and a respirator when necessary.

- Proper ventilation: Ensuring adequate ventilation to avoid inhaling harmful fumes.

- Handling chemicals safely: Following proper procedures for handling adhesives and cleaning solvents.

- Equipment usage: Following safety guidelines for operating vacuum pumps, heating equipment, and other machinery.

- Emergency preparedness: Knowing emergency procedures and having safety equipment nearby.

9. How do you stay updated with the latest advancements and best practices in mold laminating?

Staying updated is essential for continuous improvement.

I engage in these activities:

- Industry publications: Reading trade magazines and technical journals.

- Conferences and workshops: Attending industry events to learn about new technologies and techniques.

- Online resources: Utilizing online forums, webinars, and manufacturer websites for information and networking.

- Mentorship and training: Seeking guidance from experienced professionals and participating in training programs.

10. Describe a complex mold laminating project that you have worked on and explain the challenges you faced.

In a recent project, I had to laminate a complex curved mold with multiple layers of different materials.

Challenges:

- Precise alignment: Aligning the multiple layers on the curved surface was challenging.

- Vacuum bagging: Creating a tight vacuum seal around the complex shape required careful placement of vacuum ports.

- Curing time and temperature: Optimizing the curing process to ensure proper bonding was crucial.

Solutions:

- Used reference points and alignment tools for precise positioning.

- Designed a custom vacuum bagging system for the complex shape.

- Monitored the temperature closely and adjusted the curing schedule accordingly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Laminators are responsible for creating molds and laminating them onto various surfaces. They work in a variety of industries, including manufacturing, construction, and automotive. Some of their key responsibilities include:

1. Mold Preparation

Preparing molds for lamination, including cleaning, sanding, and applying release agents.

2. Laminate Application

Applying laminate to molds using a variety of techniques, such as hand-laying, vacuum bagging, and autoclaves.

3. Finishing Process

Finishing laminated molds, including trimming, sanding, and polishing.

4. Quality and Safety Regulations

Ensuring that laminated molds meet quality and safety regulations.

Interview Tips

Preparing for a Mold Laminator interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before your interview, take the time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and goals, and tailor your answers accordingly.

2. Practice Your Answers

Once you’ve done your research, take some time to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

Some questions you may want to practice answering include:

3. Be Yourself

While it’s important to be prepared for your interview, it’s also important to be yourself. The interviewer wants to get to know you and your personality, so don’t try to be someone you’re not.

4. Ask Questions

At the end of your interview, take the opportunity to ask the interviewer questions. This shows that you’re interested in the position and that you’re taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Laminator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!