Feeling lost in a sea of interview questions? Landed that dream interview for Mold Maker Apprentice but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold Maker Apprentice interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

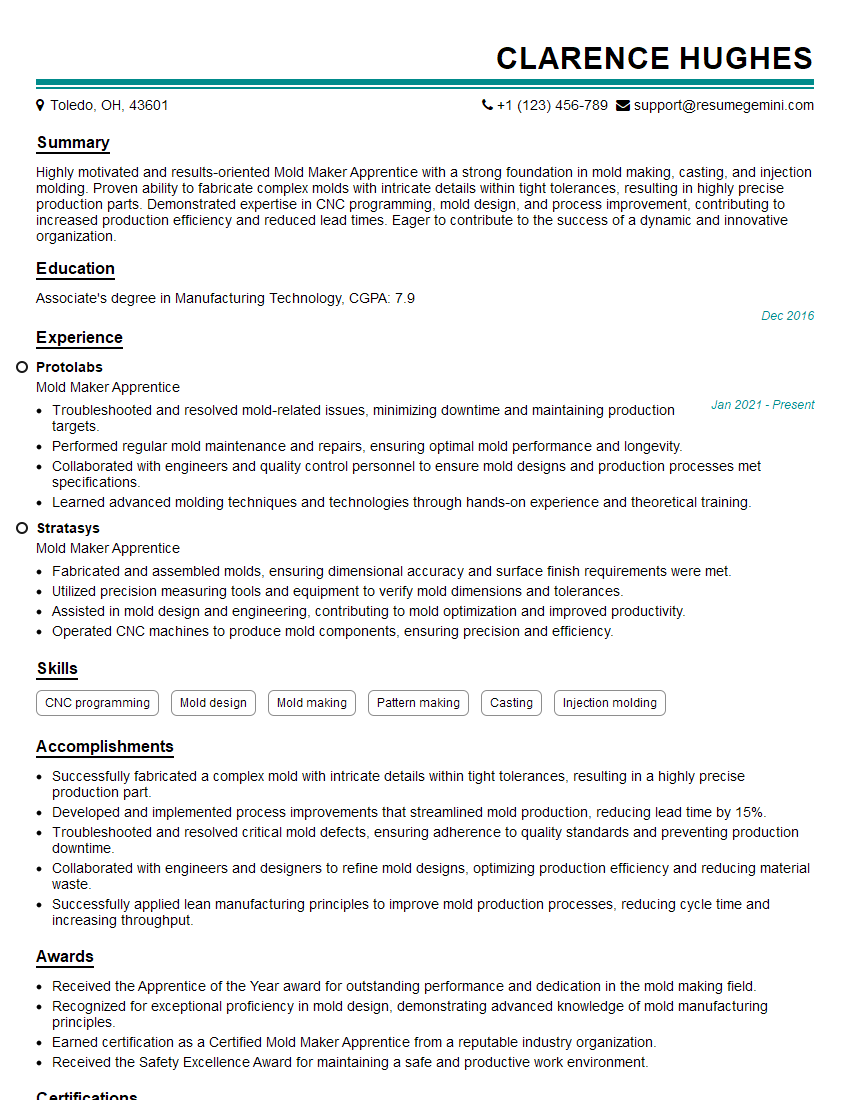

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Maker Apprentice

1. What are the different types of mold materials used in injection molding?

- Steel

- Aluminum

- Beryllium copper

- Plastic

- Ceramic

2. What is the process of mold design?

Steps of Mold Designing

- Part design

- Mold layout

- Cooling system design

- Ejection system design

- Gating system design

- Mold validation

Factors to Consider in Mold Designing

- Part geometry

- Material properties

- Molding process

- Production volume

3. What are the different types of mold making processes?

- Conventional machining

- CNC machining

- Electrical discharge machining (EDM)

- Wire EDM

- Laser cutting

4. What is the difference between a gated system and a sprue system?

- A gated system is a network of channels that carry molten plastic from the sprue to the mold cavity.

- A sprue system is a single channel that carries molten plastic from the nozzle of the injection molding machine to the gated system.

5. What are the different types of mold finishes?

- Smooth finish

- Textured finish

- Polished finish

- Chrome plated finish

- Nickel plated finish

6. What are the common defects that can occur in injection molded parts?

- Flash

- Sinks

- Voids

- Warping

- Discoloration

7. What are the different types of mold maintenance?

- Preventive maintenance

- Corrective maintenance

- Predictive maintenance

8. What are the safety precautions that should be taken when working with molds?

- Wear appropriate safety gear, including gloves, safety glasses, and ear protection

- Keep the work area clean and free of debris

- Inspect molds regularly for damage

- Never attempt to repair a mold without the proper training

- Be aware of the potential for hazardous materials, such as chemicals and solvents

9. What are the different career paths for mold makers?

- Mold maker

- Mold designer

- Mold engineer

- Mold sales representative

- Mold maintenance technician

10. What are the qualities of a successful mold maker?

- Attention to detail

- Strong mechanical skills

- Knowledge of mold design and manufacturing

- Ability to work independently and as part of a team

- Dedication to quality and safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Maker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Maker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Maker Apprentices assist experienced mold makers in a variety of tasks related to the design, production, and maintenance of molds used in manufacturing processes.

1. Assisting in Mold Design

Apprentices may provide input on mold design concepts and assist in the creation of technical drawings and specifications.

- Gathering requirements from engineers and designers

- Creating 2D and 3D models using CAD software

2. Mold Production

Apprentices work alongside mold makers to fabricate and assemble molds using various materials and techniques.

- Operating CNC machines and other equipment to shape and cut mold components

- Fitting and assembling mold parts to ensure accuracy and functionality

3. Mold Maintenance

Apprentices help maintain and repair molds to extend their lifespan and prevent production downtime.

- Inspecting molds for wear and tear

- Cleaning, lubricating, and adjusting molds as needed

4. Quality Control

Apprentices participate in quality control procedures to ensure that molds meet specifications and produce high-quality parts.

- Inspecting finished molds and parts for defects

- Identifying and addressing any issues that may impact mold performance

Interview Tips

Preparing thoroughly for a Mold Maker Apprentice interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, research the company’s history, products, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and read industry publications

- Network with professionals in the field to gain insights

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering them aloud to improve your confidence and delivery.

- Describe your experiences in mold design or production

- Explain why you are interested in a Mold Maker Apprenticeship

3. Show Your Passion

Interviewers want to know that you are genuinely passionate about the craft of mold making. Highlight your interest in design, precision, and problem-solving.

- Share examples of your personal projects or hobbies that demonstrate your skills

- Express your enthusiasm for learning and growing in the field

4. Emphasize Your Learning Mindset

Apprenticeship programs are structured for learning and development. Demonstrate your eagerness to acquire new knowledge and skills.

- Highlight your ability to follow instructions and ask clarifying questions

- Express your willingness to work in a team environment and learn from experienced mold makers

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and company.

- Ask about the apprenticeship program’s structure and training opportunities

- Inquire about the company’s goals and growth plans

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold Maker Apprentice role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.