Are you gearing up for a career in Mold Maker Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mold Maker Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

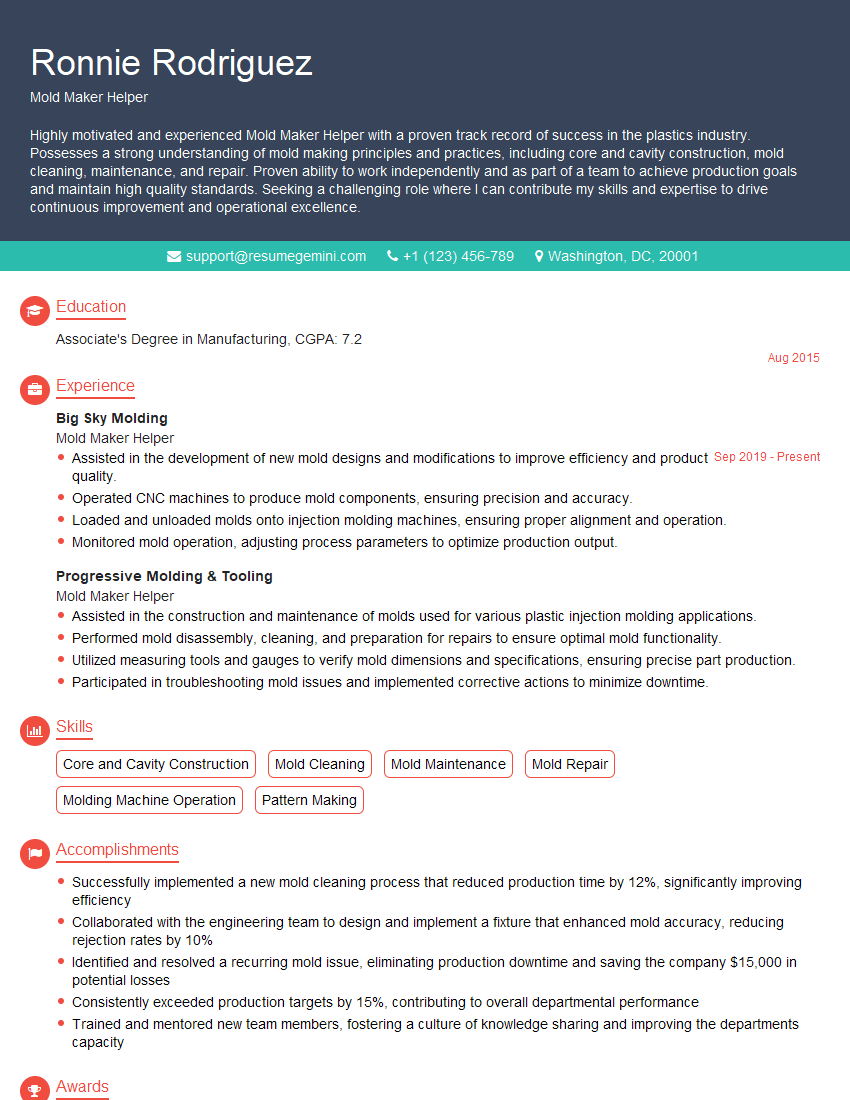

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Maker Helper

1. Explain different types of molding machines and setups?

Types of Molding Machines:

- Injection Molding Machines

- Blow Molding Machines

- Compression Molding Machines

- Transfer Molding Machines

Types of Mold Setups:

- Single Cavity Mold

- Multi-Cavity Mold

- Family Mold

- Progressive Mold

2. Describe the process of preparing a mold for production?

Mold Cleaning and Inspection

- Inspect mold for damage or wear

- Clean mold with appropriate solvents

- Apply mold release agent

Mold Assembly

- Insert mold inserts into mold base

- Tighten mold base and mold clamps

- Align mold halves and secure with mold alignment pins

Mold Testing

- Run trial shots to check mold functionality

- Adjust mold settings as needed

3. Explain the importance of mold maintenance and how it can impact the production process?

- Prevents Mold Failures: Regular maintenance helps detect and prevent potential mold failures, avoiding costly downtime.

- Optimizes Mold Performance: Proper maintenance ensures mold is operating at its best, resulting in high-quality parts and efficient production.

- Extends Mold Life: By addressing wear and tear early on, maintenance helps extend mold’s lifespan and reduce replacement costs.

- Reduces Production Defects: Well-maintained molds produce fewer defective parts, minimizing waste and improving product quality.

- Improves Safety: Regular mold maintenance ensures it operates safely, preventing accidents and workplace hazards.

4. Describe the different types of mold materials and their properties?

- Steel: Durable, strong, and resistant to wear; used for high-volume production

- Aluminum: Lightweight, corrosion-resistant, and good thermal conductivity; suitable for low-volume production

- Beryllium Copper: High strength, hardness, and thermal conductivity; used for precision molding

- Plastic: Cost-effective, lightweight, and easy to machine; suitable for prototyping and short runs

- Rubber: Flexible, resists wear and chemicals; used for molding complex shapes

5. How do you ensure dimensional accuracy and precision in mold making?

- Precise Measurements: Use precision measuring tools such as calipers, micrometers, and CMMs.

- Tight Tolerances: Establish and adhere to strict tolerances for mold dimensions.

- Calibration: Regularly calibrate measuring tools to ensure accuracy.

- CNC Machining: Utilize CNC machining for precise and repeatable mold production.

- Quality Control: Implement a rigorous quality control system to inspect molds and verify accuracy.

6. Explain the role of shrinkage in mold making and how it affects the final product?

Shrinkage is the reduction in size of a product after it cools from its molten state.

- Causes: Differential cooling rates, material properties, and mold design

- Effects: Can lead to dimensional inaccuracies, warping, and voids in the final product

- Compensation: Mold makers compensate for shrinkage by designing molds with slightly larger dimensions

7. Describe the safety precautions that must be taken when working with molds?

- Proper Ventilation: Ensure adequate ventilation to remove dust and fumes.

- Eye Protection: Wear safety glasses or goggles to protect eyes from flying debris.

- Hand Protection: Wear gloves to protect hands from chemicals and sharp edges.

- Avoid Loose Clothing: Avoid loose clothing that could get caught in machinery.

- Follow Instructions: Strictly follow manufacturer’s instructions and safety protocols.

8. How do you troubleshoot common mold defects such as voids, flash, and sink marks?

- Voids: Caused by insufficient injection pressure or trapped air; address by increasing injection pressure or optimizing venting.

- Flash: Excess material overflowing mold cavity; fix by adjusting mold alignment or using thicker mold plates.

- Sink Marks: Localized depressions in product; caused by uneven cooling; correct by adjusting cooling channels or injection parameters.

9. Describe the different types of mold cooling systems and their advantages and disadvantages?

- Water Cooling: Efficient, cost-effective, and provides precise temperature control.

- Oil Cooling: Suitable for high-temperature applications, but more expensive and requires maintenance.

- Air Cooling: Simple and cost-effective, but less efficient than water or oil cooling.

10. How do you optimize mold setup parameters such as injection pressure, mold temperature, and cooling time to improve product quality and production efficiency?

- Injection Pressure: Adjust to ensure complete filling of cavity without excessive flash.

- Mold Temperature: Optimize for proper material flow and prevent defects like sink marks.

- Cooling Time: Control to achieve desired product properties and prevent warping or deformation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Maker Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Maker Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mold Maker Helper plays a pivotal role within the Manufacturing Industry, assisting Mold Makers in the fabrication, maintenance, and repair of molds used for casting various materials, including plastics, metals, and ceramics. Their responsibilities extend to a range of tasks, encompassing:

1. Assisting Mold Makers:

Aiding Mold Makers with mold cleanup, preparation, and assembly, including tasks like cleaning, lubricating, and aligning mold components.

- Maintaining a clean and organized work area.

- Following safety protocols and maintaining a safe work environment.

2. Mold Maintenance and Repair:

Performing basic mold maintenance and repair tasks under the guidance of Mold Makers, such as cleaning mold surfaces, replacing worn-out components, and lubricating moving parts.

- Inspecting molds for wear and tear, identifying potential issues.

- Measuring and recording mold dimensions to ensure accuracy.

3. Material Handling and Storage:

Managing raw materials and finished molds, including loading, unloading, and storing materials in designated areas.

- Operating forklifts and other equipment safely and efficiently.

- Maintaining an accurate inventory of materials.

4. Quality Control:

Assisting with quality control procedures, visually inspecting molds and finished products for defects and ensuring compliance with specifications.

- Understanding and adhering to quality standards.

- Reporting any deviations or issues to Mold Makers.

Interview Tips

To effectively prepare for an interview as a Mold Maker Helper, it is essential to possess a solid understanding of the role’s responsibilities and industry-specific knowledge. Additionally, adopting the following strategies can significantly enhance your chances of success:

1. Research the Company and Industry:

Thoroughly research the company you are applying to, including their history, products, and industry standing. Delve into the Mold Making industry, its trends, and advancements.

- Visit the company’s website and social media pages.

- Read industry publications and attend online webinars.

2. Practice Your Responses:

Anticipate common interview questions and prepare thoughtful, concise responses that highlight your skills and experience. Practice delivering your answers confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Seek feedback from a friend, family member, or career counselor on your responses.

3. Showcase Your Skills and Experience:

During the interview, emphasize your relevant skills, including your precision and attention to detail, ability to work in a team environment, and commitment to quality.

- Provide specific examples of your work experience that demonstrate these qualities.

- Quantify your accomplishments whenever possible.

4. Ask Insightful Questions:

Preparing insightful questions demonstrates your engagement and interest in the role and company. Ask questions about the company’s culture, career growth opportunities, and the specific responsibilities of the Mold Maker Helper position.

- Ask about the company’s approach to quality control.

- Inquire about training and development opportunities for employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Maker Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!