Are you gearing up for a career in Mold Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mold Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

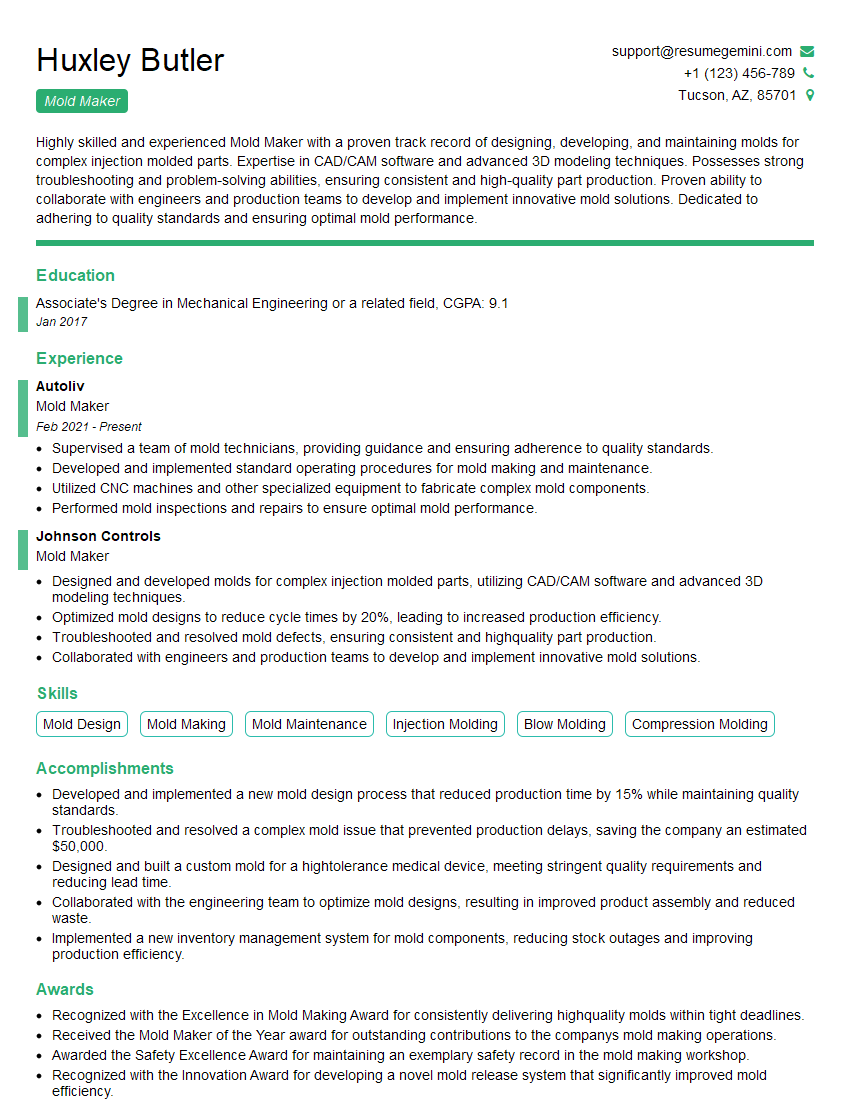

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Maker

1. Tell us about the types of molds you have worked with?

In my previous role, I was responsible for designing and creating molds for various applications, including automotive parts, medical devices, and consumer products. I have experience working with a wide range of mold types, including:

- Injection molds

- Compression molds

- Transfer Molds

- Blow Molds

- Rotational Molds

2. What is the most complex mold you have ever designed?

Design process of Complex Mold

- Identifying the product requirements and specifications.

- Creating a 3D model of the product and mold.

- Selecting the appropriate materials and manufacturing processes.

- Designing the mold to meet the required tolerances and quality standards.

Challenges Faced and Solutions Implemented

- Complex geometry and tight tolerances.

- Material selection and heat treatment.

- Mold cooling and ejection systems.

3. What are the key factors to consider when designing a mold?

When designing a mold, I consider several key factors to ensure optimal performance and product quality. These factors include:

- The type of material being molded

- The desired product geometry and dimensions

- The required production volume and cycle time

- The available manufacturing equipment

- The budget and timeline constraints

4. How do you ensure the quality of your molds?

I follow a comprehensive quality assurance process to ensure the quality and precision of my molds. This process includes:

- Using high-quality materials and components

- Employing advanced design and manufacturing techniques

- Conducting rigorous testing and inspection procedures

- Continuously monitoring and improving my processes

5. What is your experience with mold maintenance and repair?

I have extensive experience in mold maintenance and repair. I am proficient in:

- Identifying and troubleshooting mold problems

- Performing routine maintenance tasks, such as cleaning, lubrication, and adjustments

- Repairing damaged molds, including welding, grinding, and resurfacing

- Improving mold performance through modifications and upgrades

6. What are your strengths and weaknesses as a mold maker?

Strengths as Mold Maker

- Strong understanding of mold design and manufacturing principles

- Skilled in using CAD/CAM software and CNC equipment

- Proven ability to design and build high-quality molds

- Excellent problem-solving and analytical skills

- Detail-oriented and quality-conscious

Weaknesses as Mold Maker

- Limited experience with certain types of molds, such as multi-cavity molds

- Working in a fast-paced environment can sometimes lead to stress

- Continuously seeking opportunities for professional development and training to address these weaknesses.

7. What are the latest trends in mold making technology?

I stay up-to-date with the latest trends in mold making technology, including:

- Advanced materials and coatings

- Additive manufacturing techniques

- Automation and robotics

- Data analytics and predictive maintenance

- Sustainable mold making practices

8. What is your approach to working with customers?

I believe in building strong relationships with customers. My approach is to:

- Actively listen to their needs and requirements

- Provide clear and concise communication

- Offer value-added suggestions and solutions

- Exceed expectations and deliver high-quality products

9. How do you stay updated with the latest industry trends and best practices?

I stay updated with the latest industry trends and best practices by:

- Attending industry conferences and exhibitions

- Reading trade publications and technical journals

- Participating in online forums and communities

- Networking with other mold makers and professionals

- Conducting research and development projects

10. What sets you apart from other mold makers?

I am confident that my combination of technical expertise, experience, and commitment to quality sets me apart from other mold makers. I am:

- Highly skilled and experienced in all aspects of mold design and manufacturing

- Passionate about my work and dedicated to delivering exceptional results

- A team player with a strong work ethic and a positive attitude

- Have a strong understanding of the industry and market trends

- Eager to learn and grow, and continuously invest in my professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Makers are responsible for designing, constructing, and repairing molds used in manufacturing processes. They work with a variety of materials, including metal, plastic, and rubber, and use a variety of tools and equipment.

1. Design and Draft Molds

Mold Makers begin by designing molds based on the specifications of the product to be manufactured. They use computer-aided design (CAD) software to create 3D models of the molds, and then generate drawings and instructions for their construction.

2. Build and Assemble Molds

Once the mold design is complete, Mold Makers build and assemble the molds using a variety of materials and techniques. They may use metalworking tools to create mold components, and then assemble the components using welding, bonding, or other methods.

3. Test and Inspect Molds

Before molds are put into production, Mold Makers must test and inspect them to ensure that they are functioning properly. They may use a variety of testing methods, including visual inspection, dimensional measurement, and pressure testing.

4. Repair and Maintain Molds

Molds can become damaged or worn over time, so Mold Makers must be able to repair and maintain them. They may use welding, grinding, or other techniques to repair damaged molds, and they may replace worn components as needed.

Interview Tips

Preparing for a Mold Maker interview can be daunting, but by following these tips you can increase your chances of success:

1. Research the Company and Position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you to understand the company’s culture and values, and it will also give you a better idea of what the job entails.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Talk About Your Skills and Experience

The interviewer will want to know about your skills and experience as a Mold Maker. Be prepared to talk about your education, training, and work history. Highlight your relevant skills and experience, and be sure to provide specific examples of your work.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions you have about the position or the company. This shows that you’re interested in the opportunity and that you’re eager to learn more.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.