Are you gearing up for a career in Mold Making Plastics Sheets Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mold Making Plastics Sheets Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

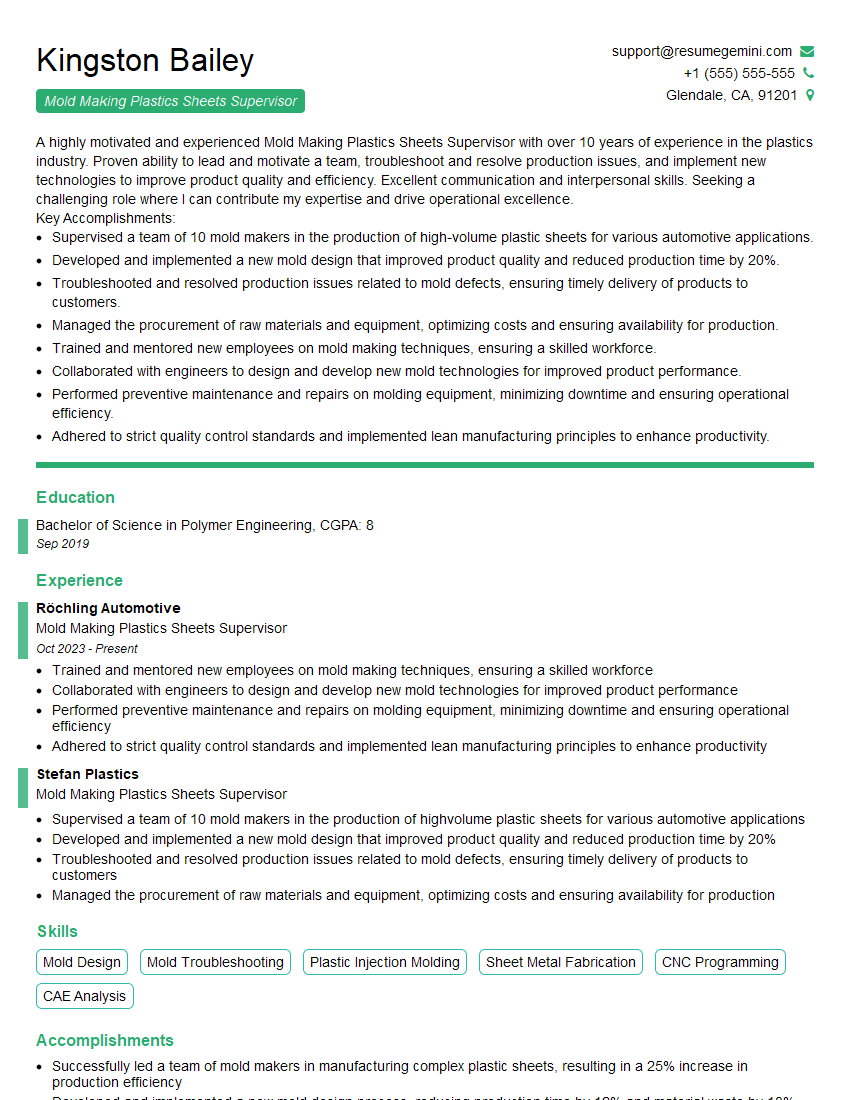

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Making Plastics Sheets Supervisor

1. What are the key factors to consider when selecting materials for mold making plastics sheets?

- Mechanical properties: strength, rigidity, toughness, dimensional stability

- Thermal properties: melting point, thermal conductivity, coefficient of thermal expansion

- Processing properties: flowability, cure time, shrinkage

- Cost and availability

2. Describe the steps involved in the mold making process for plastics sheets.

Mold Design

- Determine part geometry and tolerances

- Choose mold material and configuration

- Design gating, cooling, and ejection systems

Mold Production

- Machine mold components (cavity, core, inserts)

- Assemble and align mold components

- Finish and polish mold surfaces

3. What are the common defects that can occur during the molding process and how can they be prevented?

- Short shots: caused by insufficient material flow; can be prevented by optimizing gate design, increasing injection pressure, or reducing cycle time

- Flash: excess material around part edges; can be prevented by using proper mold clamping force, adjusting injection pressure, or improving mold sealing

- Weld lines: visible lines where two flow fronts meet; can be prevented by optimizing gate location, using higher injection speeds, or increasing mold temperature

4. How do you control the quality of molded plastics sheets?

- Establish quality standards for part dimensions, surface finish, and mechanical properties

- Monitor process parameters (injection pressure, temperature, cycle time) and make adjustments as needed

- Perform regular inspections and testing on molded parts

- Identify and address root causes of any quality issues

5. What are the latest advancements in mold making technology for plastics sheets?

- Additive manufacturing (3D printing) for mold production

- Advanced materials (e.g., high-performance polymers, metal-filled composites) for improved mold performance

- Sensors and automation for process monitoring and control

- Simulation software for optimizing mold design and predicting mold performance

6. What is the role of the Mold Making Plastics Sheets Supervisor in ensuring safety in the workplace?

- Establish and enforce safety procedures and training

- Identify and assess potential hazards

- Provide personal protective equipment (PPE)

- Monitor compliance with safety regulations

- Respond to accidents and emergencies

7. How do you manage a team of mold makers and ensure productivity?

- Set clear goals and expectations

- Provide regular feedback and training

- Empower team members and delegate tasks

- Foster a collaborative and supportive environment

- Use performance metrics to track progress and identify areas for improvement

8. What strategies do you employ to optimize mold making processes for efficiency?

- Analyze production data and identify bottlenecks

- Implement lean manufacturing principles

- Automate repetitive tasks

- Improve mold design for easier maintenance and repair

9. How do you stay up-to-date on the latest industry trends and best practices in mold making?

- Attend industry conferences and webinars

- Read trade publications and technical journals

- Network with other professionals in the field

- Seek opportunities for professional development and certification

10. Describe a situation where you had to solve a complex problem in mold making and how your approach led to a successful outcome.

Provide a detailed account of the problem, your analysis, the solutions explored, and the final outcome.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Making Plastics Sheets Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Making Plastics Sheets Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Making Plastics Sheets Supervisors oversee the production of plastic sheets, ensuring that they meet quality standards and are produced efficiently. Their responsibilities include:

1. Planning and Scheduling

Supervisors plan and schedule production runs, ensuring that materials are available and that staff is adequately trained.

- Develop production schedules based on customer orders and company requirements.

- Estimate material needs and ensure that raw materials are available when needed.

- Assign tasks and responsibilities to staff, and provide training as needed.

2. Quality Control

Supervisors monitor the quality of plastic sheets, ensuring that they meet specifications and customer requirements.

- Inspect plastic sheets for defects and ensure that they meet quality standards.

- Troubleshoot and resolve production problems that affect quality.

- Implement quality control measures to improve production processes.

3. Production Management

Supervisors oversee the production process, ensuring that it runs smoothly and efficiently.

- Monitor production progress and identify areas for improvement.

- Troubleshoot and resolve production problems, such as equipment malfunctions or quality issues.

- Implement process improvements to increase efficiency and reduce costs.

4. Safety Management

Supervisors ensure that the production process is safe for staff and complies with safety regulations.

- Implement and enforce safety policies and procedures.

- Train staff on safety procedures and ensure that they are followed.

- Inspect equipment and work areas to identify and eliminate potential hazards.

Interview Tips

To prepare for your interview for a Mold Making Plastics Sheets Supervisor position, follow these tips:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the specific requirements of the role.

- Visit the company’s website and review their mission statement, values, and recent news articles.

- Read the job description carefully and highlight the key responsibilities and qualifications.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about your experience in mold making” or “What are your strengths and weaknesses?” Prepare your answers to these questions in advance, and practice delivering them clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Tailor your answers to the specific requirements of the position and the company.

3. Be Professional and Enthusiastic

First impressions matter, so dress professionally and arrive for your interview on time. Be polite and respectful to everyone you meet, and maintain a positive attitude throughout the interview.

- Prepare a brief elevator pitch that you can use to introduce yourself and highlight your qualifications.

- Ask thoughtful questions about the position and the company to show your interest and engagement.

4. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer, thanking them for their time and reiterating your interest in the position. You can also use this opportunity to provide any additional information that you may have forgotten to mention during the interview.

- Send your thank-you note within 24 hours of the interview.

- Proofread your note carefully before sending it.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Making Plastics Sheets Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.