Feeling lost in a sea of interview questions? Landed that dream interview for Mold Polisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold Polisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

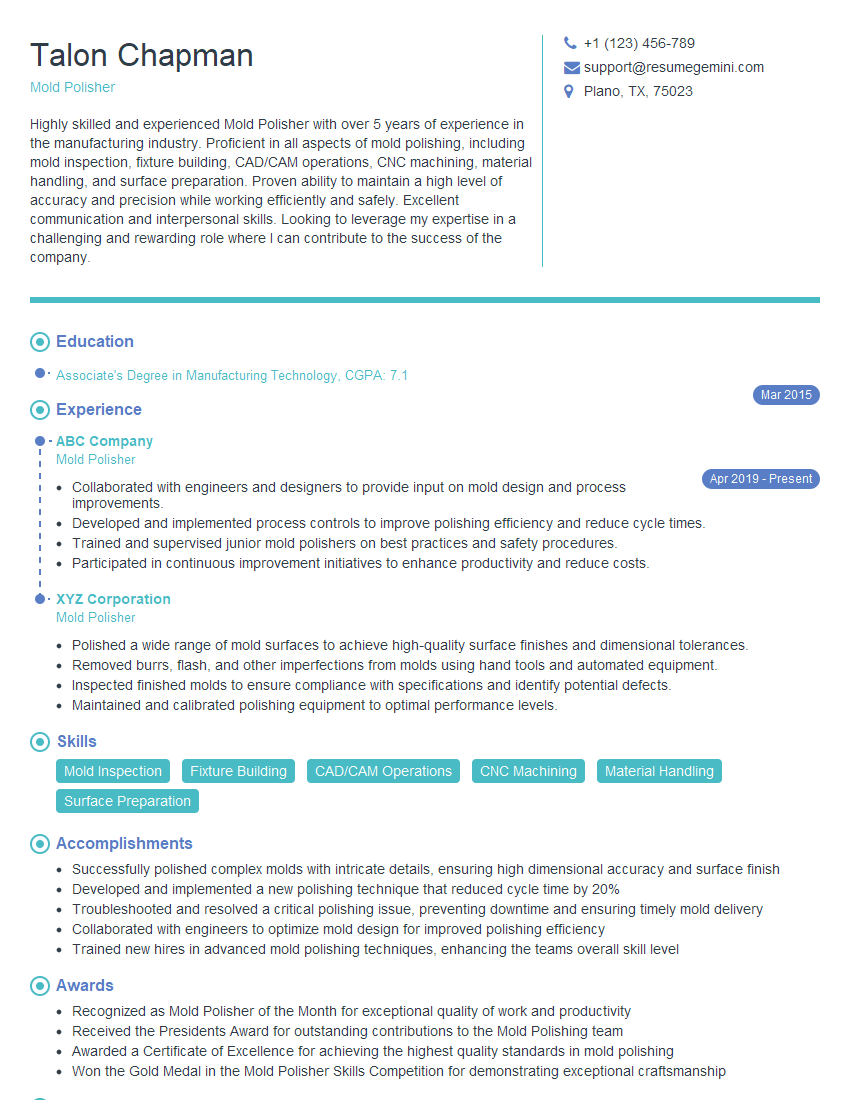

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Polisher

1. What are the different types of polishing wheels used for mold polishing?

There are various types of polishing wheels used for mold polishing, each designed for specific applications and materials. Some common types include:

- Sisal wheels: Used for initial cutting and shaping of molds, providing a good balance of aggressiveness and control.

- Buffing wheels: Soft, flexible wheels used for fine polishing and finishing, creating a smooth and shiny surface.

- Cotton wheels: Versatile wheels that can be used for both cutting and polishing, offering a range of abrasiveness depending on the grit.

- Foam wheels: Used for delicate polishing of intricate surfaces, providing a gentle touch that minimizes damage.

- Sandpaper wheels: Used for sanding and removing surface imperfections, available in various grits for different levels of aggressiveness.

2. How do you determine the correct grit size for mold polishing?

The correct grit size for mold polishing depends on the desired surface finish and the material of the mold. Here’s how to determine the appropriate grit size:

Coarse Grit (80-120):

- Used for initial cutting and shaping of molds, removing excess material and imperfections.

Medium Grit (180-220):

- Used for smoothing surfaces, removing scratches, and preparing for finer polishing.

Fine Grit (280-320):

- Used for final polishing, creating a smooth and shiny surface.

Ultra Fine Grit (500+):

- Used for ultra fine finishing, producing a mirror-like surface.

3. What are the common defects that can occur during mold polishing and how do you correct them?

Common defects that can occur during mold polishing include:

- Scratches: Caused by using too coarse a grit or applying too much pressure. Use finer grit and lighter pressure to remove scratches.

- Orange peel: A rough surface texture caused by excessive heat or improper polishing technique. Reduce heat buildup by using a water-based coolant and adjust polishing pressure and speed.

- Dipping: A depression or low spot in the polished surface. This can be corrected by using a finer grit and a slower polishing speed.

- Haze: A dull or milky appearance on the polished surface. This can be removed by using a fine grit polishing compound and a clean polishing wheel.

4. How do you ensure the dimensional accuracy of a mold after polishing?

To ensure the dimensional accuracy of a mold after polishing, the following steps can be taken:

- Use a coordinate measuring machine (CMM): A CMM can be used to measure the dimensions of the mold and compare them to the original design.

- Use a micrometer or calipers: These tools can be used to measure specific dimensions of the mold and ensure that they are within tolerance.

- Use a visual inspection: A visual inspection can be used to identify any obvious deviations from the desired shape or dimensions.

5. What safety precautions should be taken when mold polishing?

When mold polishing, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE) including eye protection, gloves, and a respirator.

- Ensure that the polishing machine is properly guarded and maintained.

- Use a water-based coolant to reduce heat buildup and prevent fires.

- Avoid breathing in dust and fumes from the polishing process.

- Keep the work area clean and free of debris.

6. What is the importance of using a clean and free polishing wheel?

Using a clean and free polishing wheel is important for several reasons:

- Prevents contamination: A dirty or contaminated polishing wheel can transfer impurities to the mold surface, affecting its quality and finish.

- Ensures consistency: A clean wheel ensures consistent polishing results and prevents the accumulation of polishing compounds that can alter the surface finish.

- Reduces defects: Dirt and debris on the polishing wheel can cause scratches or other defects on the mold surface.

7. How do you prepare a mold for polishing?

Preparing a mold for polishing involves several steps to ensure a successful polishing process:

- Cleaning: The mold should be thoroughly cleaned to remove any dirt, grease, or debris that could interfere with polishing.

- Inspection: The mold should be inspected for any defects or imperfections that need to be addressed prior to polishing.

- Masking: Any areas of the mold that should not be polished should be masked off to protect them from damage.

- Lubrication: A light lubricant can be applied to the mold surface to reduce friction during polishing.

8. What factors affect the surface finish of a polished mold?

Several factors can affect the surface finish of a polished mold, including:

- Grit size: The grit size of the polishing wheel determines the coarseness or fineness of the polish.

- Polishing pressure: The amount of pressure applied during polishing affects the depth of cut and the surface finish.

- Polishing speed: The speed of the polishing wheel influences the heat generated and the surface finish.

- Polishing compound: The type and application of the polishing compound can enhance the desired surface finish.

9. What are the different techniques used for mold polishing?

Various techniques are employed for mold polishing to achieve different surface finishes and requirements:

- Hand polishing: Using handheld polishing tools and abrasives to polish intricate or small areas.

- Machine polishing: Utilizing automated polishing machines for consistent and efficient polishing of larger surfaces.

- Vibratory polishing: Placing the mold in a vibrating bowl with abrasive media for mass finishing.

- Electrochemical polishing: Applying an electric current to remove material and achieve a smooth surface.

10. What quality control measures are implemented during mold polishing?

To ensure the quality of the polished mold, several quality control measures are typically implemented:

- Visual inspection: Examining the mold surface for any defects, scratches, or imperfections.

- Dimensional measurement: Verifying the dimensions of the polished mold using precision measuring tools.

- Surface roughness measurement: Quantifying the surface roughness of the polished mold using specialized instruments.

- Functional testing: Assessing the performance of the polished mold in its intended application.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Polishers are responsible for preparing and polishing molds used in the manufacturing process.

1. Mold Preparation

Mold Polishers prepare molds by removing any burrs or imperfections from the surface.

- Inspect molds for defects, such as scratches, dents, or cracks.

- Use hand tools, such as files, scrapers, and sandpaper, to remove burrs and imperfections.

- Clean molds using solvents or detergents to remove any dirt or debris.

2. Mold Polishing

Mold Polishers polish molds using a variety of techniques and materials.

- Apply polishing compounds to molds using a brush or cloth.

- Use a polishing machine to polish molds to a specific finish.

- Inspect polished molds to ensure that they meet the desired specifications.

3. Mold Maintenance

Mold Polishers also perform routine maintenance on molds to keep them in good working condition.

- Lubricate moving parts of molds to prevent wear and tear.

- Inspect molds for signs of damage or wear, and make repairs as necessary.

- Keep records of mold maintenance and repairs.

4. Other Duties

Mold Polishers may also perform other duties as assigned, such as:

- Assist in the design and development of new molds.

- Train new employees on mold polishing techniques.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an interview can be daunting, but there are some steps you can take to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry news and articles to stay up-to-date on the latest trends.

- Talk to people you know who work in the industry or at the company you’re applying to.

2. Practice your answers to common interview questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer behavioral questions. This method involves describing a situation, task, action, and result.

- Tailor your answers to the specific position you’re applying for. Highlight your skills and experience that are most relevant to the job.

- Be prepared to talk about your strengths and weaknesses. Be honest about your weaknesses, but also emphasize how you’re working to improve them.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and that you’re serious about the opportunity.

- Choose clothing that is clean, pressed, and appropriate for the office environment.

- Arrive at the interview location 10-15 minutes early so that you have time to relax and prepare yourself.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

4. Be yourself and be confident

The most important thing is to be yourself and be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be enthusiastic about the opportunity and express your interest in the position.

- Ask questions at the end of the interview to show that you’re engaged and interested in learning more about the company.

Next Step:

Now that you’re armed with the knowledge of Mold Polisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mold Polisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini