Feeling lost in a sea of interview questions? Landed that dream interview for Mold Puller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold Puller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

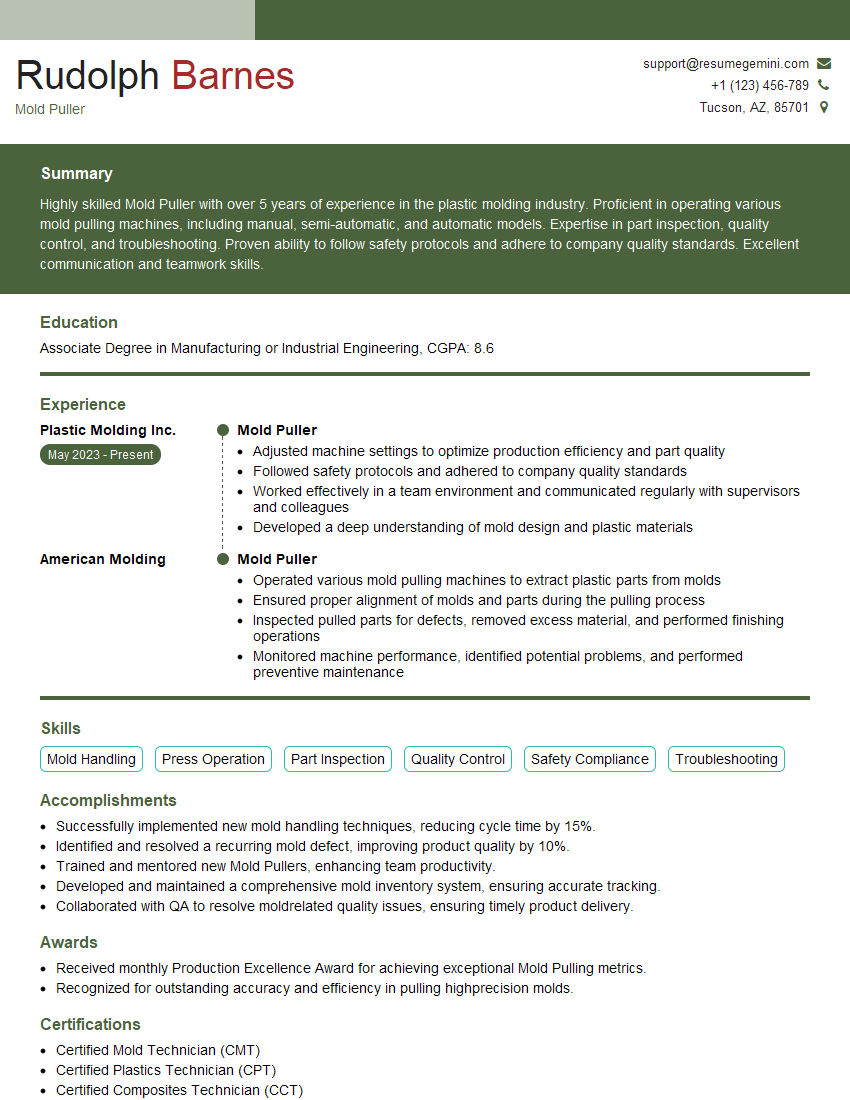

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Puller

1. Explain the process of mold pulling in detail?

The mold pulling process involves the following steps:

- Preparing the mold: The mold is cleaned and prepared by applying a release agent to prevent the part from sticking to the mold.

- Mixing and pouring the material: The mold material, such as rubber or plastic, is mixed and poured into the mold.

- Curing: The mold is allowed to cure or set, typically through heat or chemical reaction, to form the desired shape.

- Demolding: Once cured, the part can be removed from the mold.

- Post-processing: The part may undergo post-processing, such as trimming, finishing, or assembly, to complete the manufacturing process.

2. What are the different types of molds used in mold pulling?

Injection molding

- High-volume production

- Suitable for complex shapes

Compression molding

- Lower-volume production

- Simpler shapes

Transfer molding

- Medium-volume production

- Complex shapes with undercuts

Blow molding

- Production of hollow parts

- Suitable for large, simple shapes

3. What are the factors to consider when selecting a mold material?

Factors to consider when selecting a mold material include:

- Compatibility with the molding material

- Thermal conductivity and resistance

- Durability and lifespan

- Cost and availability

- Surface finish requirements

4. Describe the importance of mold maintenance and how it affects part quality?

Mold maintenance is crucial for part quality because:

- Prevents mold defects and part imperfections

- Extends the mold’s lifespan

- Improves part consistency and repeatability

- Reduces downtime and production disruptions

- Maintains optimal surface finish and dimensional accuracy

5. Explain how you troubleshoot common mold pulling problems?

Common mold pulling problems and troubleshooting tips:

- Parts sticking to the mold: Check for proper release agent application, mold temperature, and curing time.

- Part deformation or flash: Adjust injection pressure, mold temperature, or material flow rate.

- Air bubbles or voids: Improve material degassing, increase injection pressure, or optimize mold venting.

- Mold wear or damage: Inspect the mold for cracks, scratches, or other defects, and consider mold repair or replacement.

- Dimensional inaccuracies: Check mold alignment, part design, and material shrinkage rate.

6. What techniques do you use to optimize mold pulling efficiency?

Techniques to optimize mold pulling efficiency:

- Use automated mold pulling machines

- Optimize mold design for fast and efficient demolding

- Employ proper mold maintenance and cleaning practices

- Implement quality control measures to minimize part defects

- Train operators on best practices and troubleshooting techniques

7. Describe your experience in working with different types of molding materials?

I have experience working with a wide range of molding materials, including:

- Thermoplastics: ABS, PP, PE, PVC

- Thermosets: Epoxy, polyurethane, silicone

- Elastomers: Natural rubber, synthetic rubber

- Metals: Aluminum, steel, alloy

8. How do you ensure the quality of the finished parts?

To ensure the quality of finished parts, I follow these steps:

- Inspect parts for defects and imperfections

- Use measuring instruments to verify dimensional accuracy

- Conduct quality control tests as per specifications

- Monitor mold performance and adjust parameters as needed

- Document and maintain quality records

9. What is your approach to reducing waste and increasing sustainability in mold pulling?

To reduce waste and increase sustainability, I employ the following strategies:

- Use energy-efficient molding machines

- Recycle and reuse molding materials

- Implement lean manufacturing principles to minimize waste

- Educate operators on waste reduction techniques

- Explore alternative, more sustainable materials

10. Describe your experience in working with cross-functional teams?

I have extensive experience working with cross-functional teams in various mold pulling projects. I effectively collaborate with:

- Design engineers to optimize part designs for manufacturability

- Quality control personnel to ensure part quality meets specifications

- Maintenance technicians to troubleshoot and maintain molding equipment

- Production supervisors to manage production schedules and ensure efficiency

- Sales and marketing teams to gather customer requirements and provide technical support

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mold Puller is responsible for extracting molded parts from molds and performing quality checks to ensure they meet specifications.

1. Mold Extraction

- Safely remove molded parts from molds using appropriate tools

- Handle molds and parts with care to prevent damage

2. Quality Control

- Inspect molded parts for defects such as cracks, warpage, or surface imperfections

- Segregate defective parts for repair or disposal

3. Mold Maintenance

- Clean and lubricate molds to ensure smooth operation

- Monitor mold condition and report any issues to supervisors

4. Material Handling

- Transport molds and parts using appropriate equipment

- Maintain a clean and organized work area

Interview Tips

1. Research the Company and Position

Learn about the company’s products, services, and culture. Research the specific role and its requirements, including experience, skills, and qualifications.

2. Practice Common Interview Questions

Prepare for questions about your work experience, skills, and motivation. Practice answering common questions in a clear and concise manner.

3. Highlight Relevant Skills and Experience

- Emphasize your experience with mold extraction, quality control, and material handling.

- Quantify your accomplishments whenever possible to demonstrate your impact.

4. Be Prepared to Describe Your Attention to Detail

Mold Pullers must have a keen eye for detail to identify defects in molded parts. Provide specific examples of your ability to perform quality inspections.

5. Show Interest and Enthusiasm

Convey your genuine interest in the position and the company. Ask thoughtful questions and express your eagerness to contribute.

Example Outline for Interview Questions

Question:

How do you ensure the quality of molded parts?Answer:

I inspect parts thoroughly for any defects, including cracks, warpage, and surface imperfections. I use calibrated measuring tools and follow established quality control procedures to ensure compliance with specifications.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Puller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.