Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mold Sander interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mold Sander so you can tailor your answers to impress potential employers.

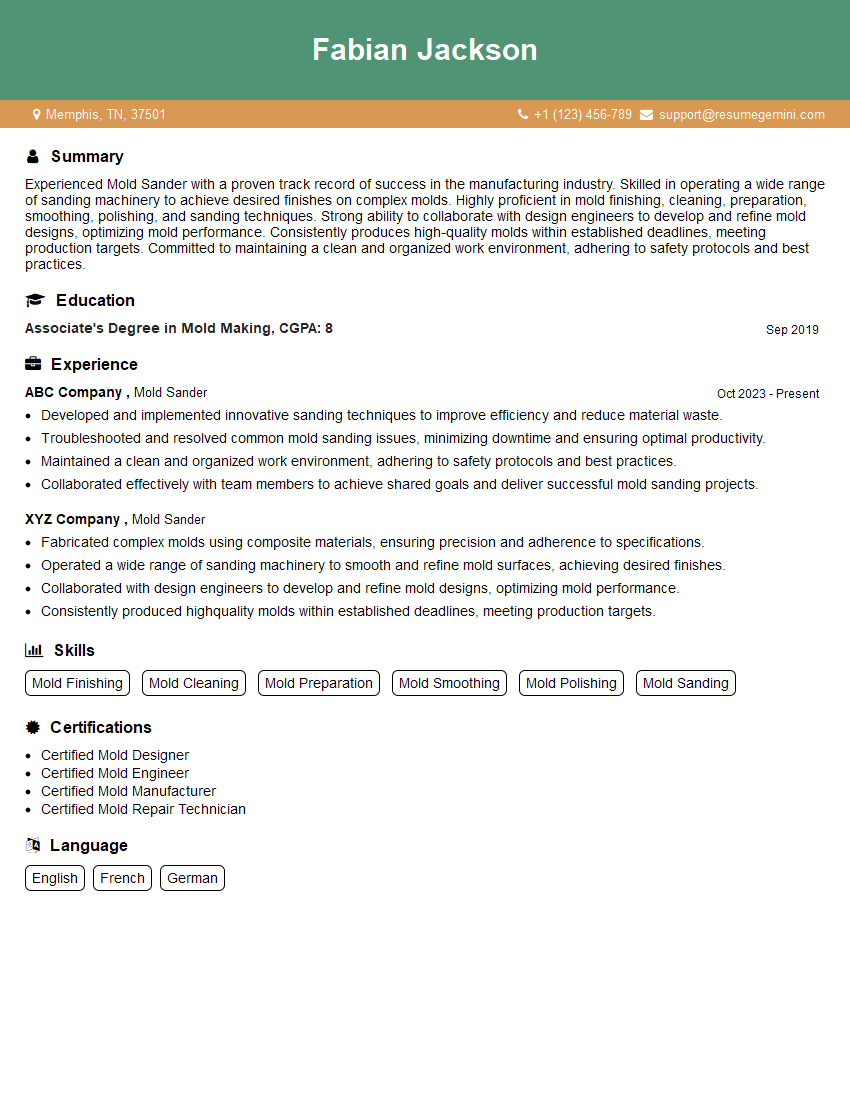

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Sander

1. What are the key technical skills required for a Mold Sander?

To be a successful Mold Sander, the following technical skills are essential:

- Proficient in using various sanding equipment, including belt sanders, orbital sanders, and random orbital sanders.

- Expertise in different sanding techniques and their applications, ensuring a smooth and consistent finish on molds.

- Knowledge of different types of abrasives, their grits, and their suitability for specific materials and finishes.

- Understanding of mold design and construction principles to identify and address potential sanding challenges.

- Attention to detail and accuracy to achieve precise and high-quality results.

2. Can you describe the process of mold sanding from start to finish?

Preparation

- Inspect the mold for any imperfections or damage.

- Select the appropriate abrasive and sanding equipment based on the material and desired finish.

- Secure the mold firmly to a stable surface.

Sanding

- Start with a coarse abrasive to remove major imperfections.

- Gradually transition to finer abrasives to achieve a smooth finish.

- Use proper sanding techniques to avoid damaging the mold or creating uneven surfaces.

Finishing

- Inspect the sanded mold for any remaining imperfections.

- Apply a sealant or finish to protect the mold from wear and tear.

3. What are some common challenges encountered in mold sanding and how do you overcome them?

- Uneven surfaces: Use a combination of sanding techniques and abrasives to achieve a consistent finish.

- Mold damage: Identify the cause of damage and use appropriate repair techniques to restore the mold’s integrity.

- Intricate designs: Use smaller sanding tools and specialized techniques to reach and sand intricate areas.

- Material compatibility: Research and select abrasives compatible with the mold material to avoid damage.

- Time constraints: Plan and prioritize tasks to meet deadlines while maintaining quality.

4. How do you maintain and calibrate sanding equipment to ensure optimal performance?

- Regular cleaning: Remove dust and debris from sanding equipment to prevent clogging and premature wear.

- Lubrication: Follow manufacturer’s recommendations for lubricating moving parts to minimize friction and extend equipment life.

- Belt tensioning: Adjust belt tension according to manufacturer’s specifications to ensure proper tracking and sanding efficiency.

- Speed settings: Calibrate sanding speed based on the material and desired finish to avoid over- or under-sanding.

- Abrasive selection: Use abrasives that are compatible with the equipment and the specific sanding task.

5. Can you explain the different sanding techniques and when to apply each one?

- Flat sanding: Used for sanding flat surfaces with orbital or random orbital sanders.

- Contour sanding: Employs sanding blocks or hand-held sanders to conform to curved surfaces.

- Edge sanding: Uses edge sanders or sanding discs to smooth and chamfer edges.

- Detail sanding: Involves using small sanding tools and abrasives to reach intricate areas.

- Dry sanding: Removes material without the use of water or lubricants.

- Wet sanding: Uses water or lubricants to reduce friction and produce a finer finish.

6. How do you determine the appropriate grit of abrasive for a specific sanding task?

- Consider the material being sanded.

- Assess the desired surface finish.

- Start with a coarser grit to remove material quickly.

- Gradually move to finer grits to refine the surface and achieve a smooth finish.

- Refer to the manufacturer’s recommendations for specific grit selection.

7. Can you describe the safety precautions that must be observed when operating sanding equipment?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Ensure proper ventilation to minimize dust inhalation.

- Inspect equipment regularly for any damage or malfunction.

- Keep work area clean and free of tripping hazards.

- Never operate sanding equipment while under the influence of drugs or alcohol.

8. How do you handle multiple sanding tasks simultaneously, ensuring quality and efficiency?

- Prioritize tasks based on urgency and importance.

- Organize workspace to minimize downtime.

- Use jigs and fixtures to streamline sanding processes.

- Communicate effectively with colleagues to avoid duplication of effort.

- Seek opportunities for automation to enhance efficiency.

9. Can you share your experience in working with different types of mold materials, such as metal, plastic, and wood?

During my previous role as a Mold Sander at [Company Name], I had the opportunity to work with a variety of mold materials, including metal, plastic, and wood. For metal molds, I used coarse abrasives to remove excess material and achieve a smooth surface. With plastic molds, I employed finer grits to avoid damaging the delicate material. For wood molds, I utilized sanding techniques that preserved the natural grain and texture.

10. Are you familiar with any industry-specific standards or regulations related to mold sanding?

Yes, I am familiar with several industry-specific standards and regulations related to mold sanding. These include:

- ANSI Z49.1-2009: Safety in Welding, Cutting, and Allied Processes

- OSHA 1910.94: Ventilation

- ISO 9001:2015: Quality Management Systems

I ensure compliance with these standards and regulations to maintain a safe and efficient work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Sanders are responsible for preparing mold surfaces for casting and shaping in industries such as fiberglass molding, composite fabrication, and plastic molding. They work closely with mold makers and production teams to ensure the accuracy and quality of the finished product.

1. Mold Preparation

Mold Sanders prepare molds for casting by cleaning, smoothing, and sealing the surfaces. They use a variety of hand tools and power tools, such as sanders, grinders, and buffers, to remove any imperfections or irregularities from the mold.

- Clean and remove debris from mold surfaces

- Smooth out any rough edges or burrs

- Seal the mold to prevent leaks or contamination

2. Mold Finishing

Once the mold is prepared, Mold Sanders apply a release agent to prevent the casting material from sticking. They also inspect the mold for any defects that could affect the quality of the finished product.

- Apply release agents to mold surfaces

- Inspect molds for defects

- Make necessary repairs or adjustments to molds

3. Casting Assistance

Mold Sanders may assist with the casting process by pouring the casting material into the mold and monitoring the curing process. They also help to remove the finished product from the mold and clean up the work area.

- Pour casting material into molds

- Monitor curing process

- Remove finished product from mold

4. Equipment Maintenance

Mold Sanders are responsible for maintaining their tools and equipment in good working condition. They perform regular cleaning and maintenance tasks, and they report any problems to their supervisor.

- Clean and maintain tools and equipment

- Report any problems to supervisor

- Follow safety procedures

Interview Tips

Preparing adequately for a Mold Sander interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific Mold Sander position. This will help you understand the company’s culture, values, and specific requirements for the role.

- Visit the company’s website

- Read industry news and articles

- Connect with current or former employees

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and articulate during the interview. Consider using the STAR method to structure your answers:

- Situation: Briefly describe the situation or task.

- Task: Explain your role and responsibilities in the situation.

- Action: Describe the specific actions you took.

- Result: State the positive outcomes or results of your actions.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Mold Sander position. Use specific examples to demonstrate your abilities in mold preparation, mold finishing, casting assistance, and equipment maintenance.

- Quantify your accomplishments whenever possible

- Use industry-specific terminology

- Be prepared to discuss your experience with different types of molds and casting materials

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the role and the organization.

- Ask about the company’s growth plans

- Inquire about the specific responsibilities of the Mold Sander position

- Ask about the company’s safety procedures

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mold Sander role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.