Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mold Tooling Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mold Tooling Technician so you can tailor your answers to impress potential employers.

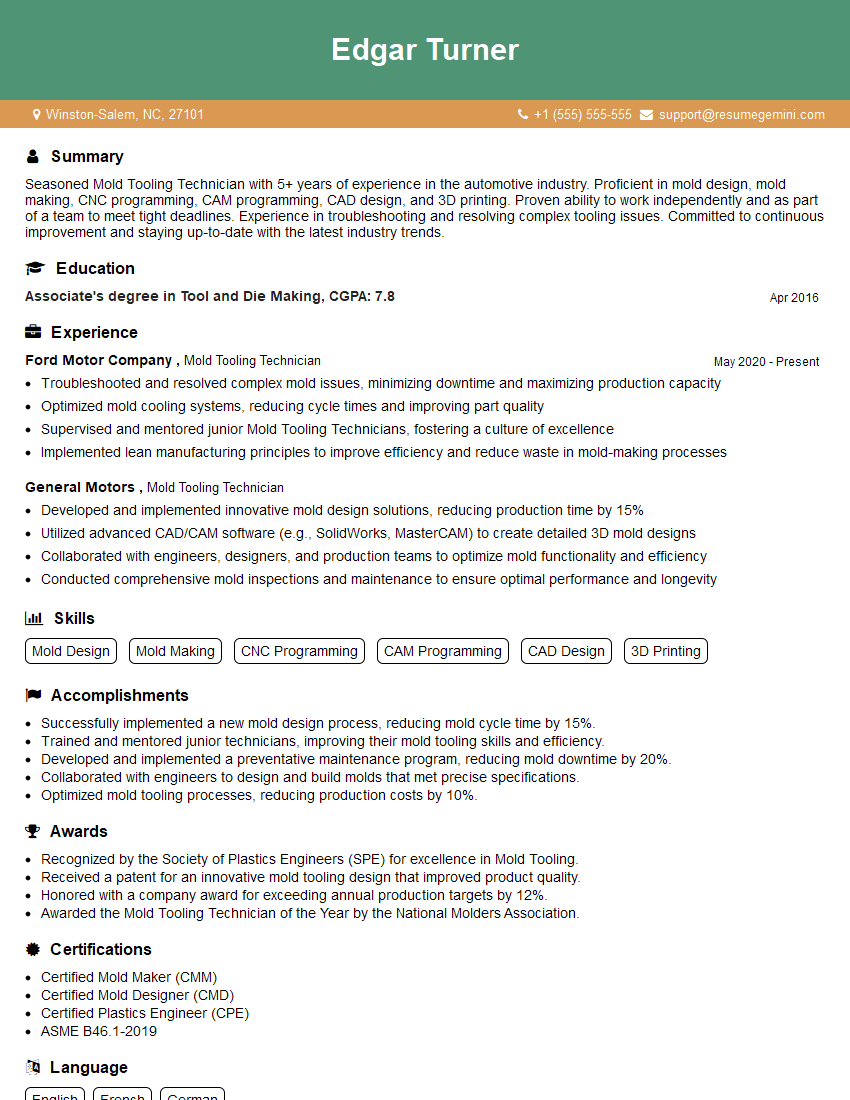

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Tooling Technician

1. How do you maintain the accuracy and precision of the molds you create?

To maintain the accuracy and precision of the molds I create, I adhere to the following techniques:

- Employing high-precision CNC machining equipment

- Utilizing computer-aided design (CAD) software for precise mold design

- Regularly calibrating and maintaining all measuring instruments

- Implementing quality control measures throughout the production process

- Following established industry standards and best practices

2. How do you manage quality control for mold production?

Process Monitoring and Inspection

- Continuously monitoring production processes to ensure adherence to specifications

- Conducting regular inspections of molds at various stages of production

- Utilizing non-destructive testing methods to assess mold integrity

- Maintaining detailed inspection records for traceability and documentation

Corrective and Preventive Actions

- Analyzing defects and implementing corrective actions to prevent recurrence

- Identifying potential quality issues and taking proactive measures to mitigate them

- Collaborating with design and engineering teams to improve mold design and production processes

3. What types of surface treatments have you applied to molds, and what are their benefits?

I have applied various surface treatments to molds to enhance their performance and durability:

- Nitriding: Improves surface hardness, wear resistance, and corrosion resistance

- Hard chrome plating: Enhances wear resistance, corrosion resistance, and release properties

- Teflon coating: Provides low friction, non-stick properties, and chemical resistance

- Electroless nickel plating: Offers corrosion resistance, wear resistance, and improved mold release

- EDM texturing: Creates micro-dimples on the mold surface to improve part release and reduce friction

4. Describe your experience in designing and modifying mold components using CAD software.

I am proficient in using CAD software for mold design and modification:

- Creating 3D models of mold components and assemblies

- Designing mold gating systems for optimal part filling

- Analyzing mold designs for manufacturability and performance

- Modifying existing mold designs to improve functionality or address production issues

- Collaborating with engineers and designers to optimize mold designs

5. How do you troubleshoot and resolve mold defects such as flash, short shots, and sink marks?

To troubleshoot and resolve mold defects, I follow a systematic approach:

- Identify the defect type and location: Determine the specific defect and its occurrence on the molded part

- Analyze mold design and process parameters: Examine mold geometry, gating system, injection settings, and material properties

- Inspect mold components: Check for wear, damage, or misalignment of mold components

- Implement corrective actions: Adjust process parameters, modify mold design, or repair/replace mold components as necessary

- Verify and document results: Test the mold after implementing corrective actions and record the outcomes for future reference

6. What safety precautions do you observe when working with molds and molding equipment?

I prioritize safety in all aspects of my work with molds and molding equipment:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs

- Follow established lockout/tagout procedures before performing maintenance or repairs

- Handle molds with care to prevent damage or injury

- Be aware of potential hazards such as hot surfaces, sharp edges, and moving machinery

- Maintain a clean and organized work area to minimize risks

7. Describe your experience in using CNC machines to manufacture mold components.

I possess expertise in operating CNC machines for mold component manufacturing:

- Program and operate CNC milling machines to create complex mold cavities and cores

- Set up and operate CNC lathes for producing mold inserts, pins, and other cylindrical components

- Optimize cutting parameters and tool selection to achieve desired surface finishes and tolerances

- Monitor machine performance and make adjustments as needed to ensure precision and efficiency

- Maintain CNC machines and perform routine maintenance to minimize downtime

8. How do you stay up-to-date with the latest advancements in mold tooling technology?

To stay current with industry advancements, I actively engage in the following:

- Attend industry conferences, workshops, and training programs

- Read technical journals and articles related to mold tooling

- Participate in online forums and discussion groups

- Network with other mold tooling professionals

- Research and evaluate new technologies and materials

9. Describe your experience in working with different types of mold materials, such as steel, aluminum, and composites.

I have worked with a wide range of mold materials, including:

- Steel: Familiar with various steel grades, heat treatments, and machining techniques

- Aluminum: Experienced in working with different aluminum alloys, including casting and machining

- Composites: Expertise in handling composite materials, such as carbon fiber and fiberglass

- Plastics: Knowledge of mold materials used for plastic injection molding

- Other materials: Experience with specialized mold materials, such as beryllium copper and ceramics

10. How do you ensure that the molds you create meet the required quality standards and customer specifications?

To ensure the quality and conformance of my molds, I adhere to the following practices:

- Design validation: Collaborate with engineers to review and validate mold designs

- Material selection: Select appropriate mold materials based on part requirements and industry standards

- Process optimization: Establish optimal molding parameters through trial runs and data analysis

- Inspection and testing: Conduct thorough inspections and testing of molds and molded parts

- Continuous improvement: Regularly review and improve mold designs and production processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Tooling Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Tooling Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Tooling Technicians play a vital role in manufacturing, ensuring the precision and quality of molds used in various industries. Their responsibilities encompass a wide range of tasks, including:

1. Mold Design and Fabrication

Contribute to mold design and development, collaborating with engineers and designers.

- Fabricate and assemble mold components using various techniques like machining, welding, and grinding.

- Ensure accuracy and precision in mold dimensions and specifications.

2. Mold Maintenance and Repair

Perform routine maintenance and repairs on molds to extend their lifespan and prevent downtime.

- Inspect molds for wear, damage, or defects, and take corrective measures.

- Repair or replace mold components as necessary.

3. Quality Control and Testing

Conduct quality checks on molds to ensure they meet customer specifications and industry standards.

- Perform dimensional measurements, surface finish inspections, and other tests.

- Provide feedback to engineers and designers to improve mold performance.

4. Collaboration and Communication

Work closely with engineers, designers, maintenance personnel, and quality control teams.

- Attend meetings, provide technical input, and participate in problem-solving discussions.

- Maintain effective communication to ensure smooth project execution.

Interview Tips

Preparing for an interview for a Mold Tooling Technician position requires careful preparation and a thorough understanding of the job’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company and specific position you are applying for. Understand their products, services, and industry reputation.

- Review the job description thoroughly and identify key responsibilities and qualifications.

- Visit the company’s website, read industry news, and gather information about their work.

2. Emphasize Your Technical Skills and Experience

Highlight your technical knowledge and skills in mold design, fabrication, maintenance, and quality control. Quantify your experience with specific examples.

- Describe projects where you successfully designed, built, or repaired molds.

- Provide specific examples of how you improved mold performance or reduced downtime.

3. Showcase Your Problem-Solving Abilities

Mold Tooling Technicians often encounter challenges and need to find solutions quickly. Demonstrate your problem-solving skills through real-life examples.

- Describe situations where you identified and resolved complex mold issues.

- Explain your approach to troubleshooting and finding innovative solutions.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your technical skills, experience, and work style. Consider the following questions:

- Tell me about your experience in mold design and fabrication.

- Describe a complex mold repair project you handled successfully.

- How do you ensure precision and accuracy in your work?

- How do you collaborate with other team members effectively?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Tooling Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!