Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Unloader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

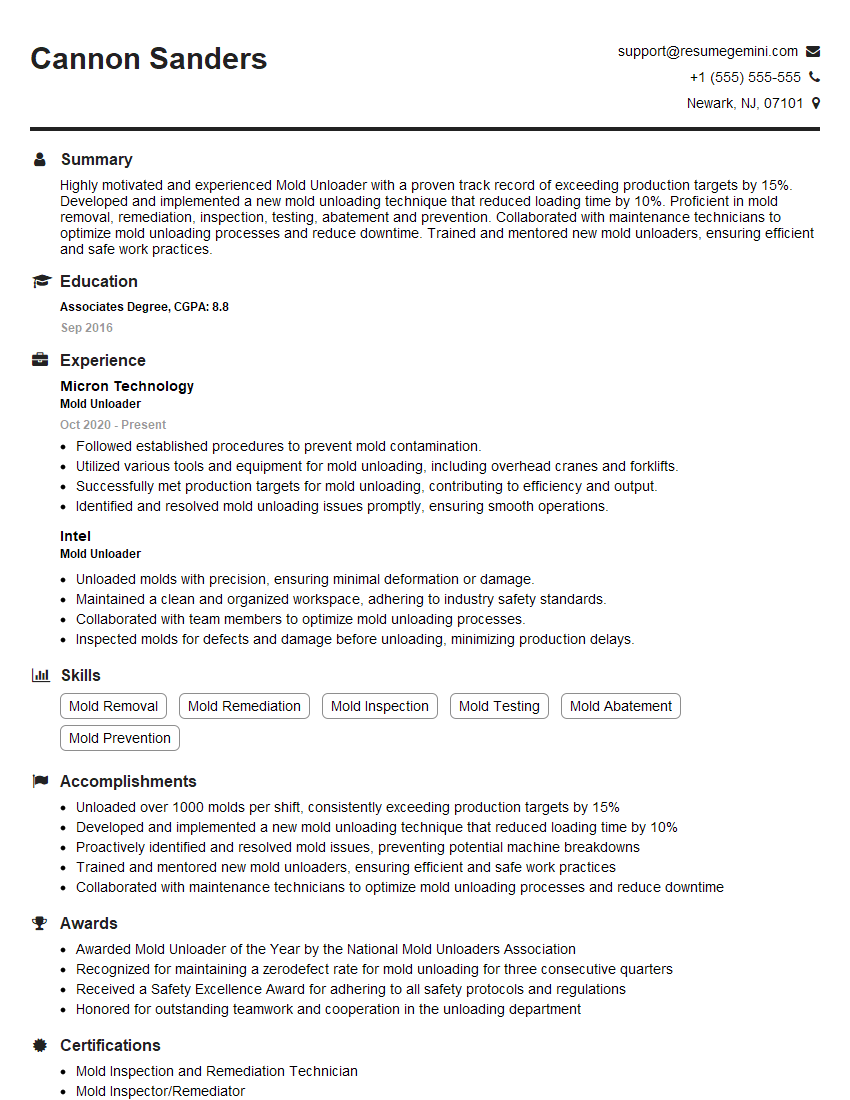

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Unloader

1. Describe the responsibilities of a Mold Unloader in the plastic injection molding process?

The primary responsibilities of a Mold Unloader are to:

- Unmold finished plastic parts from the mold using a robotic arm or manually

- Inspect parts for any defects

- Clean the mold before the next molding cycle

- Monitor the molding process to ensure quality and efficiency

- Maintain and troubleshoot equipment as needed

2. What are the essential skills that make a successful Mold Unloader?

Technical Skills

- Proficient in the operation of molding machines and robotic arms

- Understanding of different types of molds and materials

- Ability to read and interpret blueprints

- Knowledge of quality control procedures

Soft Skills

- Attention to detail

- Good communication and teamwork skills

- Ability to work in a fast-paced environment

- Physical stamina and strength

3. Explain the importance of proper mold maintenance in the plastic injection molding process?

Proper mold maintenance is crucial for the following reasons:

- Prevents defects in molded parts

- Extends the lifespan of the mold

- Improves the efficiency and productivity of the molding process

- Ensures consistent product quality

4. How would you troubleshoot a molding machine that is producing defective parts?

- Inspect the mold for any damage or contamination

- Check the molding parameters (e.g., temperature, pressure, cycle time)

- Examine the raw material for any impurities

- Consult with the machine operator and maintenance technician

- Analyze the defective parts to identify potential causes

5. Describe how you would approach continuous improvement in the mold unloading process?

Continuous improvement involves:

- Identifying areas for improvement through observation and data analysis

- Implementing changes to optimize the process (e.g., reducing cycle time, improving part quality)

- Monitoring the results and making further adjustments as needed

- Seeking feedback from team members and supervisors

6. What are the safety protocols that must be observed when working as a Mold Unloader?

- Wear appropriate personal protective equipment (e.g., gloves, safety glasses)

- Be aware of the moving machinery and potential hazards

- Follow established procedures for handling and disposing of chemicals

- Maintain a clean and organized work area

- Report any accidents or near misses immediately

7. How do you handle working in a fast-paced and physically demanding environment?

To handle working in a fast-paced and physically demanding environment, I:

- Prioritize tasks and manage my time effectively

- Communicate with my team to ensure smooth coordination

- Maintain a positive attitude and stay focused

- Take breaks when needed to prevent fatigue

- Follow proper ergonomic practices to minimize physical strain

8. Explain your understanding of injection molding process?

The injection molding process involves:

- Injection of molten plastic into a mold cavity

- Cooling and solidification of the plastic

- Ejection of the finished part from the mold

- Molding parameters (e.g., temperature, pressure, cycle time) affect the quality and dimensions of the molded part

9. Describe a situation where you successfully resolved a problem with the molding process?

I once encountered a problem where the molded parts had surface defects. I inspected the mold and found that the cooling channels were clogged, which caused the plastic to cool unevenly. I cleaned the channels and adjusted the cooling parameters. As a result, the surface defects were eliminated.

10. How do you stay up to date on the latest advancements in plastic injection molding?

- Attend industry conferences and training seminars

- Read technical journals and online resources

- Network with other professionals in the field

- Participate in discussions and webinars

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Unloader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Unloader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold unloaders are responsible for a variety of tasks in a manufacturing environment. These tasks may vary depending on the specific employer and industry, but some common responsibilities include:

1. Unloading Molds

Mold unloaders are responsible for unloading molds from molding machines. This involves removing the finished product from the mold and placing it in a designated area. Mold unloaders must be careful not to damage the mold or the finished product.

2. Cleaning Molds

Mold unloaders are also responsible for cleaning molds. This involves removing any debris or residue from the mold to ensure that it is ready for the next use.

3. Inspecting Molds

Mold unloaders are responsible for inspecting molds for any damage or defects. They must report any problems to their supervisor so that the mold can be repaired or replaced.

4. Other Duties

In addition to the above, mold unloaders may also be responsible for other tasks such as:

- Operating forklifts or other equipment to move molds

- Maintaining a clean and organized work area

- Following safety procedures

- Working with other team members to ensure that production goals are met

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company and the Position

Before you go to your interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to answer questions about the position and your qualifications.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked. These questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Dress Professionally

The way you dress for your interview can make a big impression on the interviewer. It is important to dress professionally and conservatively. This means wearing a suit or business casual attire.

4. Be Punctual

Punctuality is important for any interview. It shows the interviewer that you are respectful of their time and that you are organized and efficient.

5. Be Confident

Confidence is key in any interview. It is important to believe in yourself and your abilities. This will come across to the interviewer and increase your chances of success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Unloader interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!