Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mold Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mold Worker so you can tailor your answers to impress potential employers.

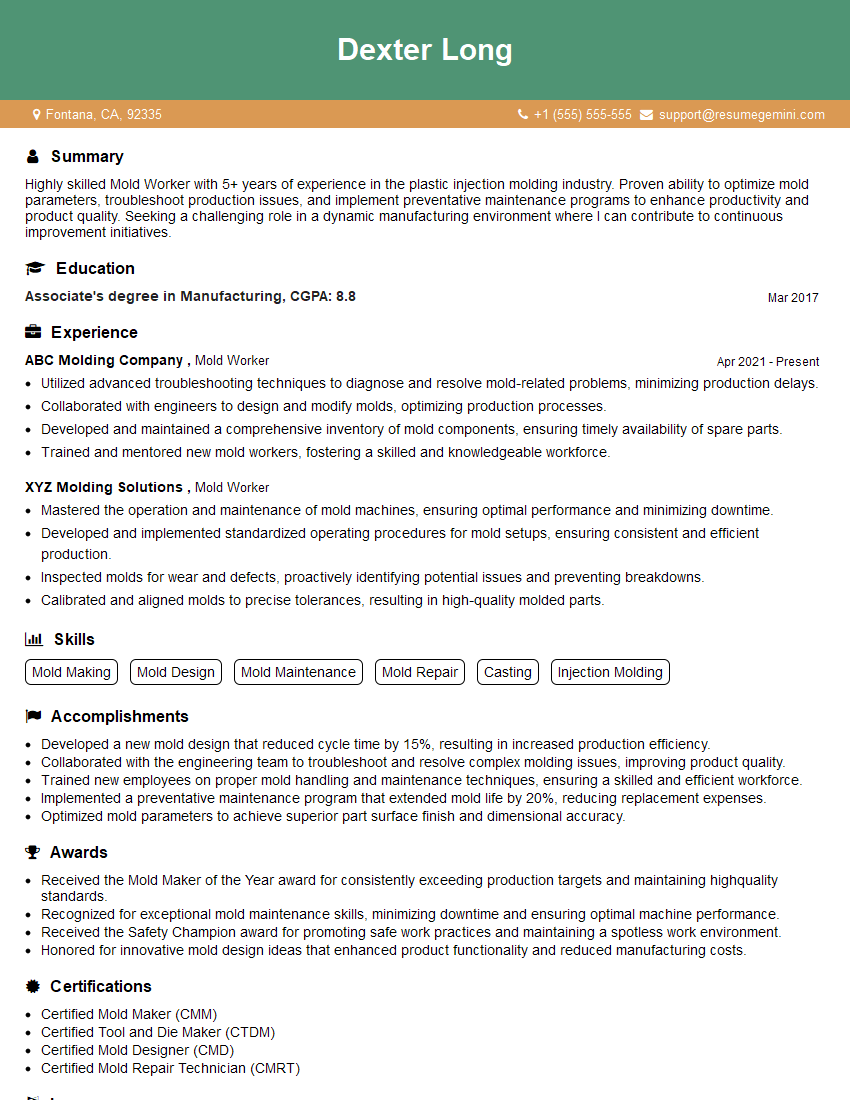

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Worker

1. Explain different types of molds used in plastic molding?

- Injection molds: These are used to produce high-volume plastic parts with complex shapes. They consist of two halves that are clamped together and injected with molten plastic.

- Blow molds: These are used to produce hollow plastic parts such as bottles and containers. They consist of two halves that are clamped together and air is blown into the molten plastic to form the desired shape.

- Compression molds: These are used to produce flat or simple-shaped plastic parts. They consist of two heated platens that are pressed together to compress the molten plastic into the desired shape.

- Transfer molds: These are used to produce plastic parts with complex shapes or inserts. They consist of two halves that are clamped together and molten plastic is transferred from a separate pot into the mold cavity.

- Rotational molds: These are used to produce hollow plastic parts with uniform wall thickness. They consist of a mold that is rotated while molten plastic is poured into it. The plastic then solidifies on the inside of the mold.

2. Describe the process of injection molding?

Mold preparation

- The mold is cleaned and prepared for use.

- The mold is then heated to the desired temperature.

- The mold is then clamped together and locked.

Injection

- Molten plastic is injected into the mold cavity.

- The plastic is injected under high pressure.

- The plastic fills the mold cavity and takes the shape of the mold.

Cooling

- The plastic is allowed to cool and solidify.

- The mold is then opened.

- The plastic part is ejected from the mold.

3. What are the different factors that affect the quality of plastic molded parts?

- The type of plastic used

- The mold design

- The molding process

- The quality of the raw materials

- The environmental conditions

4. What are the different types of defects that can occur in plastic molded parts?

- Short shots: These occur when the mold cavity is not completely filled with plastic.

- Flash: This occurs when excess plastic escapes from the mold cavity.

- Sinks: These occur when the plastic shrinks as it cools, causing a depression in the surface of the part.

- Voids: These occur when air bubbles are trapped in the plastic.

- Weld lines: These occur when two streams of plastic meet in the mold cavity.

5. What are the different methods used to inspect plastic molded parts?

- Visual inspection: This is the most common method of inspection.

- Dimensional inspection: This is used to measure the dimensions of the part.

- Functional testing: This is used to test the function of the part.

- Destructive testing: This is used to test the strength of the part.

6. What are the different types of maintenance that are performed on molds?

- Preventive maintenance: This is performed on a regular basis to prevent problems from occurring.

- Corrective maintenance: This is performed to fix problems that have occurred.

- Predictive maintenance: This is used to predict when problems are likely to occur.

7. What are the different types of safety precautions that should be taken when working with molds?

- Wear proper safety gear.

- Be aware of the hazards of working with molds.

- Follow the manufacturer’s instructions for operating molds.

- Inspect molds regularly for damage.

- Report any problems with molds to your supervisor immediately.

8. What are the different types of skills that are required to be a successful mold worker?

- Technical skills

- Mechanical skills

- Problem-solving skills

- Communication skills

- Teamwork skills

9. What are the different types of career opportunities that are available to mold workers?

- Mold maker

- Mold designer

- Mold inspector

- Mold maintenance technician

- Molding machine operator

10. What are your strengths and weaknesses as a mold worker?

- Strengths: I am a highly skilled mold worker with over 10 years of experience. I am proficient in all aspects of mold making, from mold design to mold maintenance. I am also a certified mold inspector.

- Weaknesses: I am not very good at working under pressure. I also tend to be a perfectionist, which can sometimes lead to delays in my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Workers play a critical role in the manufacturing process by creating and maintaining the molds used to shape various products. Their responsibilities encompass a wide range of tasks, including:

1. Mold Design and Fabrication

Analyze product specifications and work with engineers to design and construct molds.

- Utilize CAD/CAM software to create 3D models and technical drawings.

- Select and prepare materials, such as steel, aluminum, or plastic, for mold construction.

2. Mold Maintenance and Repair

Inspect and perform regular maintenance on molds to ensure optimal performance and lifespan.

- Troubleshoot and resolve mold malfunctions, such as wear and tear, alignment issues, or defects.

- Repair or replace mold components as needed to maintain precision and efficiency.

3. Mold Testing and Optimization

Conduct trial runs to test the functionality and quality of newly fabricated or repaired molds.

- Monitor production processes and collect data to identify areas for improvement.

- Make adjustments to mold design and parameters to optimize production yield and product quality.

4. Safety and Compliance

Adhere to safety protocols and maintain a clean and organized work environment.

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection.

- Follow established procedures and regulations to ensure compliance with industry standards.

Interview Tips

To ace the interview for a Mold Worker position, candidates should prepare thoroughly and showcase their skills and knowledge. Here are some tips to help you make a strong impression:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and reputation.

- Visit the company website and read industry publications.

- Identify specific qualities and skills that the company values and tailor your resume and answers accordingly.

2. Highlight Your Technical Expertise

Emphasize your proficiency in mold design, fabrication, maintenance, and repair.

- Quantify your accomplishments and provide specific examples of your work.

- Discuss your experience with different types of molds and materials.

3. Demonstrate Problem-solving Abilities

Showcase your ability to identify and resolve mold-related issues.

- Describe situations where you successfully diagnosed and fixed mold malfunctions.

- Explain your approach to troubleshooting and optimizing mold performance.

4. Emphasize Safety and Attention to Detail

Stress your commitment to safety and your meticulous approach to work.

- Highlight your knowledge of industry safety regulations and your track record of maintaining a safe work environment.

- Provide examples of how you ensure precision and quality in your work.

5. Be Enthusiastic and Professional

Convey your passion for mold work and your willingness to contribute to the company’s success.

- Show that you are eager to learn and grow within the organization.

- Dress professionally and maintain a positive attitude throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.