Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mold Yarn Supervisor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

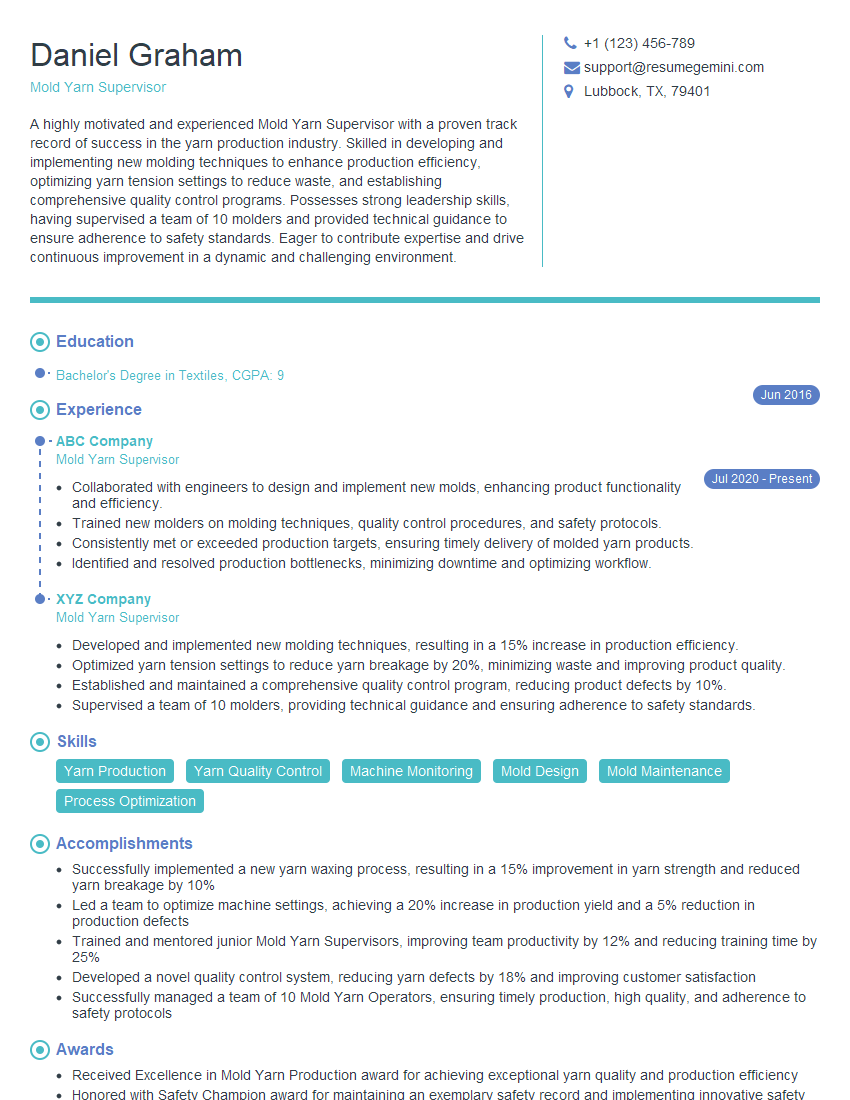

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Yarn Supervisor

1. How do you ensure the consistency and quality of the yarn produced?

To maintain consistency and quality, I would implement the following measures:

- Raw material inspection: Inspect incoming raw materials to ensure they meet specifications.

- Process control: Monitor and adjust equipment settings throughout the production process to maintain optimal conditions.

- In-process testing: Conduct regular testing of yarn properties (e.g., strength, elongation) to identify any deviations.

- Data analysis: Analyze historical data to identify trends, optimize processes, and prevent future problems.

- Employee training: Ensure that operators are properly trained on all aspects of yarn production and quality control.

2. Describe the key technical parameters you monitor to maintain the spinning operation within specifications.

Process Parameters

- Rotor speed: Impacts yarn strength and elongation.

- Spinning tension: Affects yarn evenness and hairiness.

- Draft ratio: Influences yarn count and quality.

- Fiber length: Affects yarn strength and appearance.

- Moisture content: Impacts yarn elasticity and spinnability.

Equipment Parameters

- Machine temperature: Affects yarn quality and production efficiency.

- Rotor condition: Worn or damaged rotors can compromise yarn quality.

- Spindle alignment: Misalignment can cause yarn breakage and unevenness.

3. How do you troubleshoot and resolve common yarn defects, such as neps, slubs, and unevenness?

To troubleshoot and resolve yarn defects, I would follow these steps:

- Identify the defect: Visually inspect the yarn to determine the specific defect.

- Trace the source: Examine the production process to identify the stage where the defect occurred.

- Analyze the cause: Consider potential factors contributing to the defect, such as raw material quality, equipment malfunction, or operator error.

- Implement corrective measures: Adjust process parameters, replace defective components, or provide additional training to operators as needed.

- Monitor the results: Track the effectiveness of corrective measures and make further adjustments if necessary.

4. How do you optimize the production efficiency of the spinning machines while maintaining yarn quality?

To optimize production efficiency while maintaining yarn quality, I would:

- Minimize downtime: Schedule regular maintenance and promptly address any equipment issues.

- Automate processes: Utilize technology to streamline production steps and reduce manual labor.

- Improve operator efficiency: Provide training and empower operators to make minor adjustments.

- Optimize process parameters: Conduct experiments to determine the optimal settings for maximum efficiency and quality.

- Monitor performance: Track key metrics and make adjustments as needed to maintain optimal performance.

5. How do you manage and motivate a team of machine operators?

To manage and motivate a team of machine operators, I would:

- Set clear goals and expectations: Communicate performance standards and objectives to the team.

- Provide training and support: Ensure that operators have the knowledge and skills to excel in their roles.

- Foster a positive work environment: Create a supportive and respectful workplace that encourages collaboration and innovation.

- Recognize and reward achievements: Acknowledge and celebrate team successes to motivate and build morale.

- Empower operators: Grant autonomy to operators within defined parameters to promote ownership and accountability.

6. Describe your experience in implementing and improving quality management systems.

In my previous role, I led the implementation of a comprehensive quality management system based on ISO 9001 standards. I:

- Developed and documented quality policies and procedures: Ensured adherence to standards and best practices.

- Established a quality control plan: Outlined inspection and testing methodologies to monitor product quality.

- Conducted regular internal audits: Identified areas for improvement and maintained compliance with standards.

- Analyzed data and implemented corrective actions: Used statistical tools to identify trends and resolve quality issues.

- Improved customer satisfaction: Reduced product defects and enhanced overall quality, resulting in increased customer loyalty.

7. What are your strategies for reducing production costs without compromising product quality?

To reduce production costs without compromising quality, I would:

- Optimize resource utilization: Maximize equipment efficiency, minimize waste, and reduce energy consumption.

- Negotiate with suppliers: Seek competitive pricing for raw materials and equipment while ensuring quality.

- Implement lean manufacturing principles: Eliminate waste, reduce lead times, and improve overall operational efficiency.

- Explore automation and technology: Utilize technology to streamline processes and reduce labor costs.

- Analyze production data: Identify cost drivers and areas for improvement through data analysis.

8. How do you stay updated on industry trends and advancements in yarn production technology?

To stay updated on industry trends and advancements, I:

- Attend conferences and workshops: Participate in industry events to learn about new developments.

- Read industry publications and journals: Stay abreast of latest research and best practices.

- Visit yarn manufacturing facilities and exhibitions: Observe firsthand the latest technologies and innovations.

- Engage with industry experts: Network with peers and thought leaders to exchange knowledge and ideas.

- Research online resources: Utilize the internet to access webinars, technical articles, and industry news.

9. How do you ensure the health and safety of your team while working around machinery?

To ensure the health and safety of my team, I would:

- Develop and enforce safety protocols: Establish clear guidelines for operating machinery and handling materials.

- Provide training and instruction: Educate operators on safety hazards, proper use of equipment, and emergency procedures.

- Conduct regular safety inspections: Identify and mitigate potential hazards in the workplace.

- Encourage reporting of incidents: Foster a culture of open communication to address any safety concerns promptly.

- Provide necessary personal protective equipment: Equip operators with appropriate safety gear, such as hearing protection, gloves, and safety glasses.

10. How do you handle situations where there is a conflict between production targets and quality standards?

When faced with a conflict between production targets and quality standards, I would:

- Prioritize quality: Maintain adherence to quality standards as the primary goal.

- Analyze the situation: Assess the root cause of the conflict and explore alternative solutions.

- Communicate with management: Discuss the situation and seek support in finding a balanced approach.

- Adjust production targets: If necessary, negotiate revised production targets that ensure both quality and efficiency.

- Implement quality control measures: Enhance inspection and testing processes to prevent defects and maintain standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Yarn Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Yarn Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Yarn Supervisors are responsible for directing and overseeing the production of mold yarn. They ensure that the yarn meets quality standards and is produced efficiently and safely,

1. Manage Production Processes

intro paragraph

- Plan, schedule, and coordinate production activities to meet customer orders and production targets.

- Monitor production processes and make adjustments as needed to ensure efficient and effective operation.

- Troubleshoot and resolve production issues and problems to minimize downtime and maintain production schedules.

2. Quality Control

intro paragraph

- Establish and implement quality standards for mold yarn production.

- Inspect and test mold yarn to ensure compliance with quality specifications.

- Identify and correct any non-conformances or defects in the production process.

3. Team Management

intro paragraph

- Lead, motivate, and develop a team of production operators.

- Train and supervise production operators on proper operating procedures and safety protocols.

- Assign responsibilities, delegate tasks, and monitor performance to ensure production goals are met.

4. Inventory Management

intro paragraph

- Monitor raw material inventory levels and place orders for replenishment when necessary.

- Manage finished goods inventory and ensure proper storage and handling.

- Conduct inventory audits and reconcile stock levels to maintain accurate records.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of acing it.

1. Research the Company and Position

Take the time to thoroughly research the company and the specific role you are applying for. Understand the company’s mission, values, recent news, and industry standing. This will help you demonstrate your interest and knowledge during the interview.

- Visit the company’s website and social media pages.

- Read articles and press releases about the company and its industry.

2. Practice Common Interview Questions

Familiarize yourself with common interview questions and practice answering them in a clear and concise manner. This will help you feel more confident and prepared during the actual interview.

- Tell me about yourself.

- Why are you interested in this position?

3. Highlight Your Relevant Skills and Experience

Tailor your resume and cover letter to the specific requirements of the job. During the interview, emphasize your skills and experience that are most relevant to the role. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments with data and metrics whenever possible.

- Explain how your previous experience has prepared you for this role.

4. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- What are the biggest challenges facing the company right now?

- What are the opportunities for professional growth within the organization?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Yarn Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.