Are you gearing up for a career in Molded Frames Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Molded Frames Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

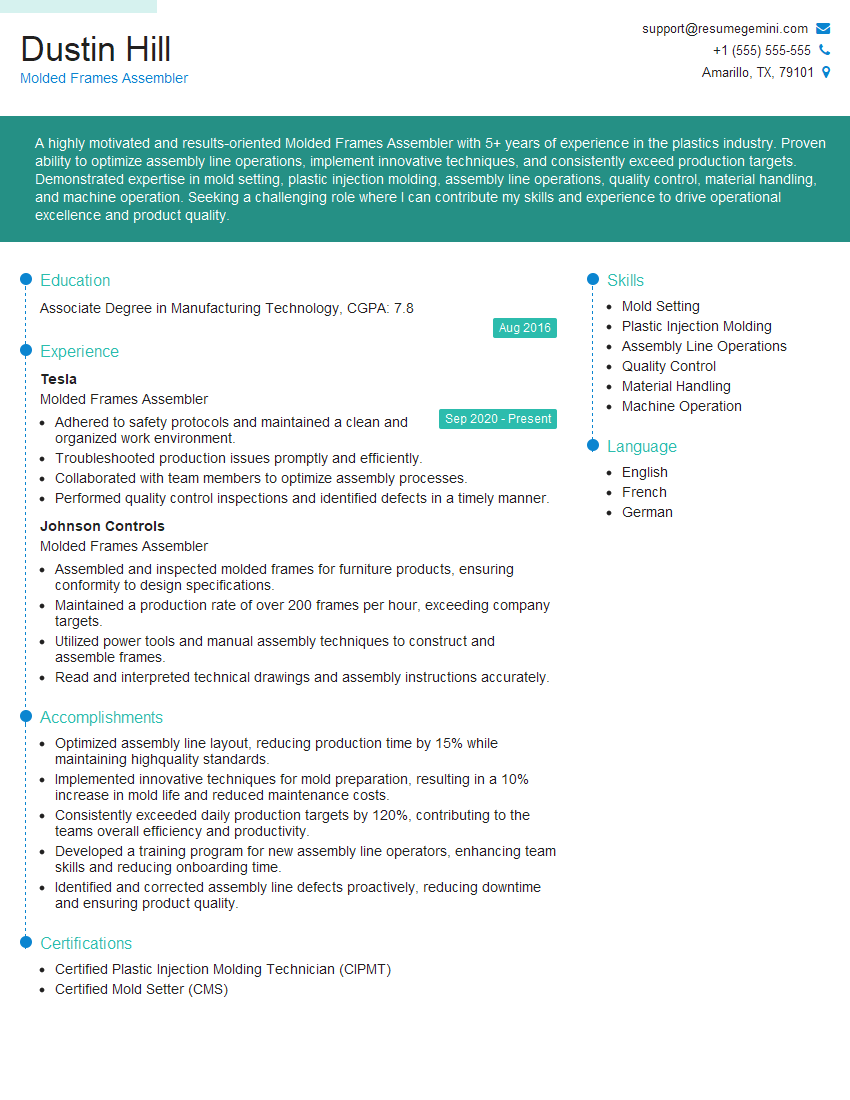

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molded Frames Assembler

1. What is the process of molding frames?

The process of molding frames involves several steps:

- Preparing the mold: The mold is prepared by applying a release agent to prevent the frame from sticking to it.

- Mixing the resin: The resin is mixed with a hardener according to the manufacturer’s instructions.

- Pouring the resin into the mold: The resin mixture is poured into the mold and allowed to cure at a controlled temperature.

- Curing the resin: The resin is allowed to cure for a specified period, typically in a heated environment.

- Demolding: Once the resin has cured, the frame is removed from the mold.

2. What are the different types of resins used in frame molding?

Polyester resins:

- Low cost

- Versatile and easy to work with

- Good strength and durability

Epoxy resins:

- Higher strength and durability than polyester resins

- More resistant to chemicals and UV radiation

- Longer cure time and more expensive

Phenolic resins:

- Excellent electrical insulation properties

- Good heat resistance

- Brittle and less resistant to impact

3. What are the key factors to consider when choosing a resin for frame molding?

- Strength and durability: The resin should provide adequate strength and durability for the intended application.

- Resistance to chemicals and UV radiation: If the frame will be exposed to harsh chemicals or UV radiation, a more resistant resin should be chosen.

- Cure time: The cure time of the resin should be compatible with the production schedule.

- Cost: The cost of the resin should be considered within the overall budget.

4. What are the different types of molds used in frame molding?

- Single-piece molds: These molds are made from a single piece of material, such as metal or silicone.

- Two-piece molds: These molds consist of two parts that are joined together to form the mold cavity.

- Multi-piece molds: These molds are made from multiple parts that are assembled to form the mold cavity.

5. What are the factors to consider when choosing a mold for frame molding?

- Size and shape of the frame: The mold must be large enough to accommodate the desired frame size and shape.

- Complexity of the frame: More complex frames require molds with more detail.

- Material of the mold: Different mold materials have different properties, such as durability, flexibility, and heat resistance.

- Cost of the mold: The cost of the mold should be considered within the overall budget.

6. What are the different methods used to apply release agents to molds?

- Spraying: Release agents can be applied to molds using a spray gun.

- Brushing: Release agents can be applied to molds using a brush.

- Wiping: Release agents can be applied to molds using a cloth or sponge.

7. What are the common problems encountered in frame molding and how can they be resolved?

- Air bubbles: Air bubbles can be removed by degassing the resin before pouring it into the mold.

- Warping: Warping can be prevented by using a rigid mold and curing the frame at a controlled temperature.

- Cracking: Cracking can be prevented by using a flexible mold and avoiding excessive force during demolding.

- Discoloration: Discoloration can be prevented by using UV-resistant resins and protecting the frame from direct sunlight.

8. What are the safety precautions that should be taken when working with resins and molds?

- Wear appropriate personal protective equipment: This includes gloves, eye protection, and a respirator.

- Work in a well-ventilated area: Resins and molds can emit harmful fumes.

- Avoid skin contact with resins: Resins can cause skin irritation and allergic reactions.

- Dispose of resins and molds properly: Resins and molds should be disposed of according to local regulations.

9. What are the quality control measures that should be implemented in frame molding?

- Inspect the molds: Molds should be inspected for any defects before each use.

- Inspect the resin: Resin should be inspected for any impurities or discoloration before use.

- Inspect the finished frames: Finished frames should be inspected for any defects, such as air bubbles, warping, or cracking.

- Record the inspection results: Inspection results should be recorded and kept for future reference.

10. What are the industry trends in frame molding?

- Increased use of automation: Automation is being used to improve efficiency and reduce labor costs.

- Development of new resins: New resins are being developed with improved properties, such as higher strength and durability.

- Increased focus on sustainability: There is a growing demand for sustainable frame molding practices.

- Growth in the use of 3D printing: 3D printing is being used to create complex frames with unique designs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molded Frames Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molded Frames Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molded Frames Assemblers are responsible for assembling and finishing molded frames for a variety of products, including furniture, appliances, and electronics. They work in a fast-paced environment, and must be able to meet production quotas while maintaining high quality standards.

1. Assemble molded frames

Assemble molded frames according to specifications, using a variety of tools and equipment.

- Inspect frames for defects and ensure they meet quality standards.

- Attach hardware and other components to frames.

2. Finish molded frames

Finish molded frames by sanding, painting, or staining them.

- Apply protective coatings to frames.

- Inspect frames for defects and ensure they meet quality standards.

3. Pack and ship molded frames

Pack and ship molded frames according to specifications.

- Label frames with appropriate information.

- Load frames onto shipping containers.

4. Maintain work area

Maintain work area clean and organized.

- Follow safety procedures.

- Report any unsafe conditions or equipment malfunctions.

Interview Tips

To ace your interview for a Molded Frames Assembler position, it’s important to prepare by reviewing the job description and researching the company. Here are some additional tips:

1. Dress professionally and arrive on time.

First impressions matter, so dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the job and that you respect their time.

2. Be prepared to answer questions about your experience and skills.

The interviewer will likely ask you about your experience and skills. Be prepared to answer questions about your experience assembling and finishing molded frames. You should also be able to demonstrate your knowledge of the different types of tools and equipment used in this field.

3. Be prepared to talk about your safety record.

Safety is important in any manufacturing environment, so be prepared to talk about your safety record. The interviewer will likely ask you about your experience with safety procedures and your knowledge of OSHA regulations.

4. Be prepared to talk about your teamwork skills.

Molded Frames Assemblers often work in teams, so be prepared to talk about your teamwork skills. The interviewer will likely ask you about your experience working with others and your ability to contribute to a team environment.

5. Be prepared to ask questions.

Asking questions at the end of the interview shows the interviewer that you’re interested in the job and that you’re taking the interview seriously. Prepare a few questions to ask the interviewer about the company, the position, and the work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molded Frames Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!