Feeling lost in a sea of interview questions? Landed that dream interview for Molded Goods Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Molded Goods Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

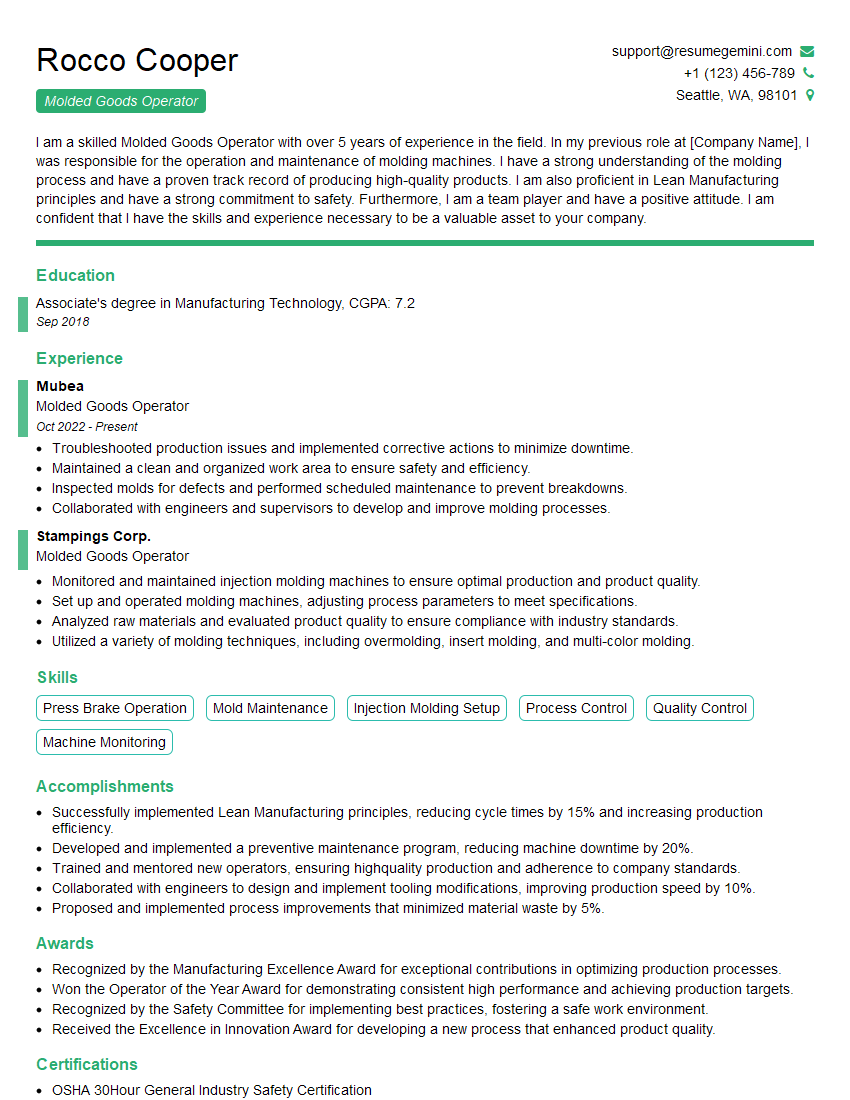

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molded Goods Operator

1. Describe the process of molding rubber components, including the different types of molds and molding machines used?

The process of molding rubber components typically involves the following steps:

- Selecting the appropriate type of mold and molding machine for the specific component being produced.

- Preparing the mold by cleaning and releasing agents.

- Mixing the rubber compound according to the specified recipe.

- Loading the rubber compound into the mold.

- Curing the rubber compound under heat and pressure.

- Ejecting the molded component from the mold.

- Inspecting the molded component for defects.

There are many different types of molds and molding machines used in the rubber industry. The most common types of molds are compression molds, transfer molds, and injection molds. Compression molds are used to produce simple, flat or cylindrical components. Transfer molds are used to produce more complex components with undercuts or internal cavities. Injection molds are used to produce high-volume, precision components.

The type of molding machine used depends on the type of mold and the size and complexity of the component being produced. Compression molding machines are used to produce small to medium-sized components. Transfer molding machines are used to produce larger, more complex components. Injection molding machines are used to produce high-volume, precision components.

2. What are the different types of rubber compounds used in molded goods manufacturing?

Raw Materials

- Natural rubber

- Synthetic rubber

- Fillers

- Plasticizers

- Curing agents

Classification Basis

- Natural vs. Synthetic

- Filler Type

- Curing System

3. How do you ensure the quality of molded rubber components?

There are several ways to ensure the quality of molded rubber components:

- Using high-quality raw materials.

- Following the correct molding process.

- Inspecting the molded components for defects.

- Testing the molded components to ensure they meet the required specifications.

- Using statistical process control (SPC) to monitor and improve the molding process.

By following these steps, manufacturers can ensure that they are producing high-quality molded rubber components that meet the needs of their customers.

4. What are the common defects that can occur in molded rubber components?

- Flash

- Voids

- Cracks

- Sinks

- Weld lines

- Discoloration

- Dimensional errors

These defects can be caused by a variety of factors, including:

- Improper mold design

- Incorrect molding process

- Defective raw materials

- Improper handling of the molded components

5. How do you troubleshoot common defects in molded rubber components?

Troubleshooting common defects in molded rubber components involves the following steps:

- Identify the defect.

- Determine the cause of the defect.

- Implement corrective actions to eliminate the cause of the defect.

- Verify that the corrective actions have been effective.

Some common defects and their causes include:

- Flash: Caused by excessive material in the mold or incorrect mold closing pressure.

- Voids: Caused by entrapped air or insufficient material in the mold.

- Cracks: Caused by excessive stress or strain on the molded component.

- Sinks: Caused by shrinkage of the molded component during cooling.

- Weld lines: Caused by the fusion of two or more streams of material in the mold.

- Discoloration: Caused by contamination of the raw materials or the molding process.

- Dimensional errors: Caused by incorrect mold dimensions or improper molding process.

6. What are the different types of equipment used in the production of molded rubber components?

- Mixing mills

- Calenders

- Extruders

- Molding presses

- Curing ovens

- Testing equipment

Each type of equipment has a specific role in the production process. Mixing mills are used to mix the raw materials together. Calenders are used to sheet the rubber compound. Extruders are used to form the rubber compound into the desired shape. Molding presses are used to mold the rubber compound into the desired shape. Curing ovens are used to cure the rubber compound. Testing equipment is used to test the quality of the molded rubber components.

7. What are the safety precautions that must be taken when working with molded rubber components?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Be aware of the potential hazards of working with rubber compounds, such as allergies and skin irritation.

- Follow all safety procedures and guidelines.

- Use proper lifting techniques when handling heavy objects.

- Keep the work area clean and free of hazards.

- Report any accidents or injuries to your supervisor immediately.

8. What are the latest trends in the molded rubber components industry?

- Increased use of automation

- Development of new materials

- Growing demand for molded rubber components in various industries

- Focus on sustainability

These trends are shaping the future of the molded rubber components industry and creating new opportunities for growth.

9. How do you stay updated on the latest developments in the molded rubber components industry?

- Attend industry conferences and trade shows.

- Read industry publications.

- Network with other professionals in the industry.

- Take advantage of online resources.

By staying up-to-date on the latest developments, I can ensure that I am using the most current techniques and technologies in my work.

10. Why are you interested in working as a Molded Goods Operator in our company?

I am interested in working as a Molded Goods Operator in your company because I am passionate about the rubber industry and I am eager to learn more about the molding process. I have a strong understanding of the different types of rubber compounds and the molding equipment used in the industry. I am also a quick learner and I am always looking for new challenges. I am confident that I can be a valuable asset to your team and I am excited to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molded Goods Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molded Goods Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molded Goods Operators are responsible for the production of molded rubber and plastic goods. They operate a variety of machines to mold, cure, and finish these products.

1. Operate Molding Machines

Molded Goods Operators use molding machines to create rubber and plastic products. They set up the machines, load them with raw materials, and monitor the molding process.

- Follows established procedures to produce molded rubber and plastic goods.

- Operates molding machines, presses, and other equipment to form and shape rubber and plastic materials.

2. Inspect Finished Products

Molded Goods Operators inspect finished products to ensure that they meet quality standards. They check for defects, such as cracks, bubbles, or discoloration.

- Inspects molded products for defects and non-conformities.

- Maintains records of production and quality control data.

3. Maintain Equipment

Molded Goods Operators maintain equipment to ensure that it is in good working condition. They clean and lubricate machines, and replace worn parts.

- Cleans and lubricates machinery and equipment.

- Performs minor repairs and maintenance on molding machines.

4. Troubleshoot Problems

Molded Goods Operators troubleshoot problems that occur during the molding process. They identify the cause of the problem and take corrective action.

- Identifies and resolves problems that occur during the molding process.

- Makes adjustments to molding machines to improve product quality.

Interview Tips

Preparing for a job interview can be stressful, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Take some time to learn about the company you are interviewing with and the position you are applying for. This will help you answer questions intelligently and show that you are genuinely interested in the opportunity.

- Practice your answers to common interview questions.

- Be prepared to talk about your experience and qualifications.

2. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This does not mean you have to wear a suit, but your clothes should be clean, pressed, and appropriate for the office environment.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

3. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and let your personality shine through.

- Be confident and enthusiastic.

- Be prepared to ask questions about the company and the position.

4. Follow Up

After your interview, send a thank-you note to the interviewer. This is a great way to show your appreciation for their time and to reiterate your interest in the position.

- Thank the interviewer for their time and consideration.

- Reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Molded Goods Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Molded Goods Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini