Are you gearing up for an interview for a Molder Feeder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Molder Feeder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

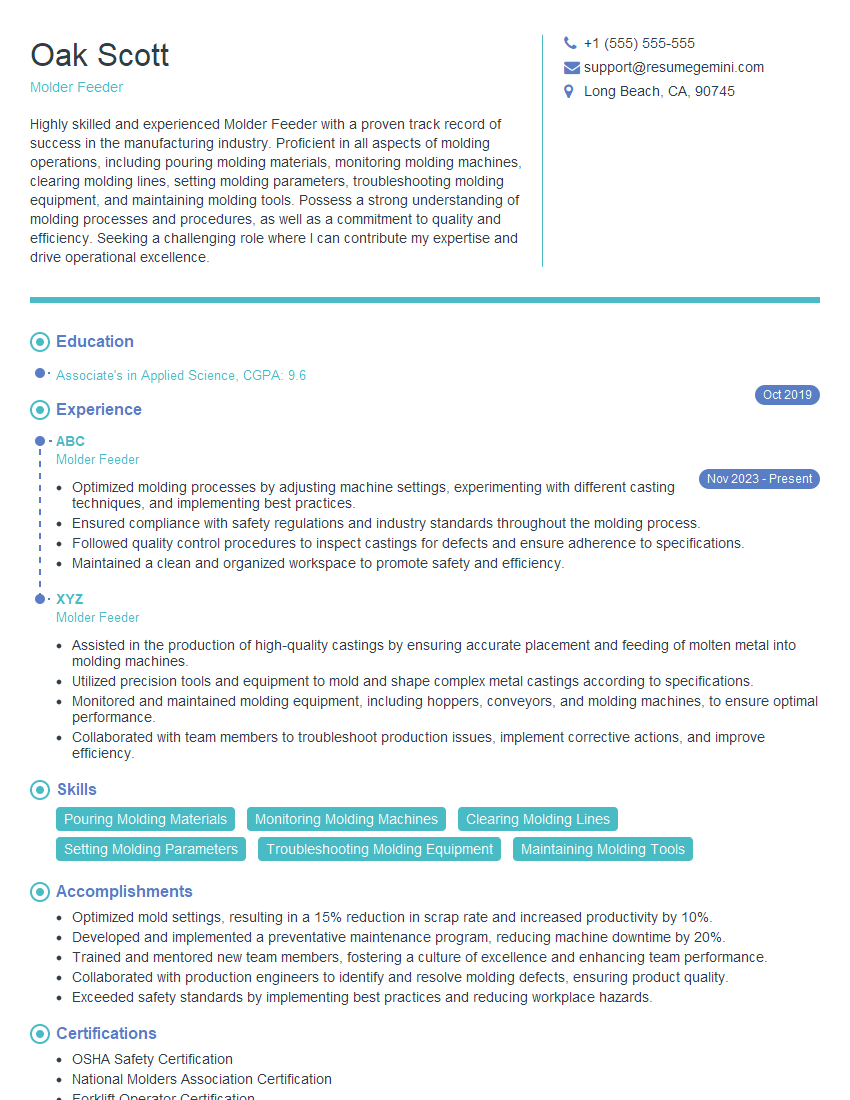

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molder Feeder

1. Explain the process of preparing the mold for molding?

To prepare the mold for molding, I would:

- Clean the mold surface to remove any dirt or debris.

- Apply a release agent to prevent the molded part from sticking.

- Place the mold in the correct position on the molding machine.

- Secure the mold in place using clamps or bolts.

2. Describe the different types of molding machines and their applications?

Injection molding machines

- Used to produce high-volume, complex parts with precise dimensions.

- Suitable for a wide range of materials, including plastics, metals, and ceramics.

Compression molding machines

- Used to produce large, simple parts with uniform thickness.

- Suitable for materials that require high pressure to mold, such as rubber and thermoset plastics.

Transfer molding machines

- Used to produce parts with complex shapes and thin walls.

- Suitable for materials that are difficult to flow, such as highly viscous plastics and rubber.

3. Explain the factors that affect the quality of the molded part?

The quality of the molded part is affected by:

- Mold design and construction

- Material properties

- Molding process parameters (temperature, pressure, and cycle time)

- Environmental conditions

4. How do you troubleshoot common molding defects?

To troubleshoot common molding defects, I would:

- Identify the type of defect.

- Determine the possible causes of the defect.

- Implement corrective actions to eliminate the defect.

Some common molding defects include:

- Flash

- Sinks

- Voids

- Warping

5. What are the safety precautions that should be followed when operating a molding machine?

When operating a molding machine, I would always follow the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Be aware of the moving parts of the machine and keep hands clear.

- Never attempt to clean or adjust the machine while it is running.

- Follow all lockout/tagout procedures before performing any maintenance or repairs.

- Report any unsafe conditions to a supervisor immediately.

6. How do you maintain and calibrate a molding machine?

To maintain and calibrate a molding machine, I would:

- Perform regular inspections and cleanings.

- Calibrate the machine according to the manufacturer’s specifications.

- Replace worn or damaged parts.

- Keep a maintenance log to track all maintenance and repairs.

7. What are the different types of molding materials and how are they selected?

The different types of molding materials include:

- Plastics

- Metals

- Ceramics

The type of material is selected based on the desired properties of the molded part, such as strength, durability, and cost.

8. What are the different types of mold designs and how are they used?

The different types of mold designs include:

- Two-plate molds

- Three-plate molds

- Multi-cavity molds

The type of mold design is selected based on the complexity of the part and the production volume.

9. What are the different process parameters that can be adjusted to affect the quality of the molded part?

The different process parameters that can be adjusted to affect the quality of the molded part include:

- Temperature

- Pressure

- Cycle time

These parameters are adjusted based on the type of material being molded and the desired properties of the molded part.

10. What are the different quality control procedures that can be used to ensure the quality of the molded parts?

The different quality control procedures that can be used to ensure the quality of the molded parts include:

- Visual inspection

- Dimensional inspection

- Functional testing

These procedures are used to identify any defects or non-conformances in the molded parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molder Feeder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molder Feeder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Molder Feeder plays a pivotal role in the molding process by being responsible for ensuring the proper functioning of the molder machine and efficiently feeding raw materials into the system.

1. Operating and Maintaining the Molder Machine

The primary responsibility involves operating and maintaining the molder machine, ensuring its proper functionality and safe operation. This includes:

- Monitoring the machine’s performance, identifying and addressing any potential issues promptly.

- Performing regular maintenance tasks, such as cleaning, lubrication, and adjustments, to maintain optimal machine performance.

2. Feeding Raw Materials

Feeding raw materials into the molder machine is another crucial task. This involves:

- Loading and unloading raw materials, such as sand, binders, and resins, into the machine’s hopper.

- Adjusting the material feed rate and monitoring the material flow to ensure proper molding.

3. Quality Control

Molder Feeders are responsible for ensuring the quality of the molded products. This includes:

- Inspecting molded products for defects and taking corrective actions as needed.

- Monitoring the overall molding process and identifying any potential quality issues.

4. Safety Compliance

Adhering to safety regulations and protocols is paramount. Molder Feeders are responsible for:

- Following established safety procedures and wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area to minimize hazards.

Interview Tips

To ace an interview for a Molder Feeder position, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you prepare:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific job requirements. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience operating and maintaining molding machines. Share examples of how you have effectively fed raw materials and ensured quality control. Quantify your accomplishments whenever possible, using specific metrics or results.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Anticipate questions about your understanding of the molding process, safety protocols, and troubleshooting techniques.

4. Be Enthusiastic and Confident

Convey your enthusiasm for the role and your confidence in your abilities. Show that you are eager to contribute to the team and make a positive impact within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molder Feeder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.