Are you gearing up for an interview for a Molder Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Molder Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

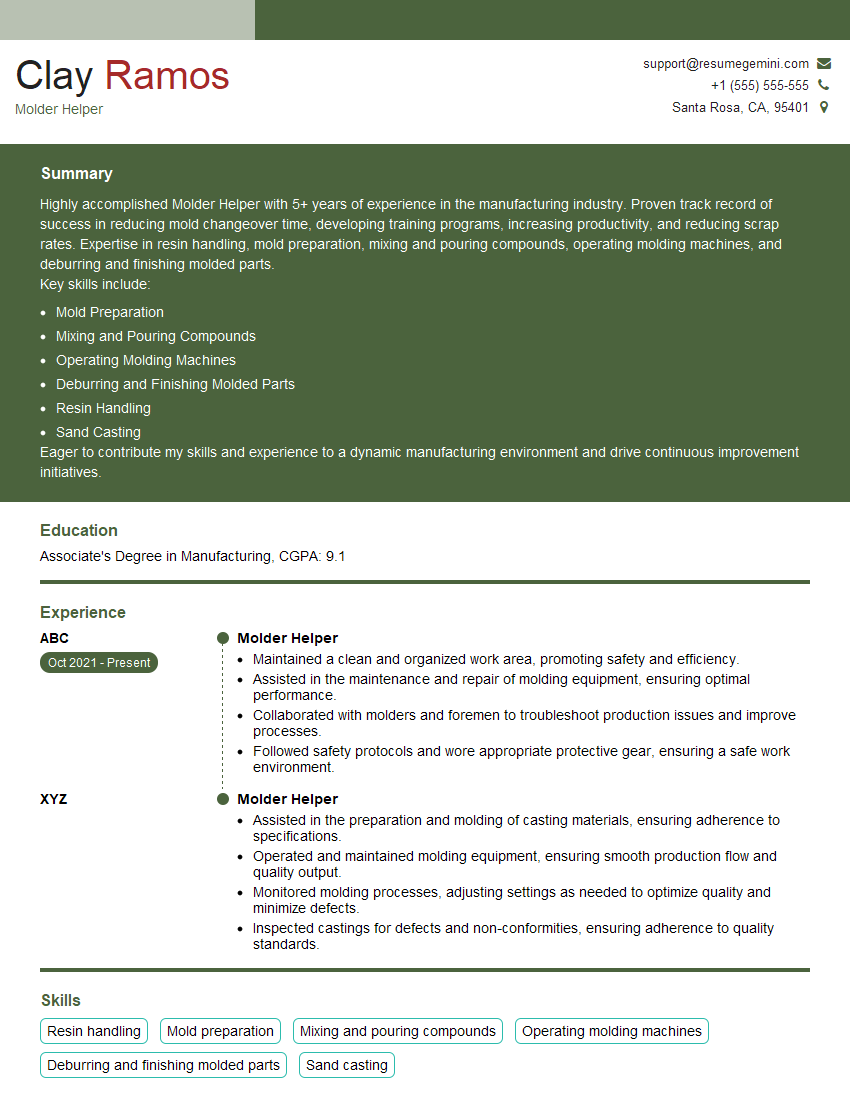

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molder Helper

1. How do you ensure that the molds are properly prepared before pouring the molten metal?

As a Molder Helper, I play a crucial role in preparing molds for pouring molten metal. I adhere to the following steps to ensure that the molds are properly prepared:

- Cleaning and Inspection: I thoroughly clean the molds to remove any dirt, debris, or contaminants that could affect the casting process.

- Coating: I apply a release agent or mold coating to the mold surfaces to prevent the metal from sticking and to ensure easy removal of the casting.

- Mold Assembly: I carefully assemble the mold components, such as cope and drag, ensuring proper alignment and securing them with clamps.

- Venting: I create vents in the mold to allow gases to escape during the pouring process, preventing defects in the casting.

- Visual Inspection: I perform a final visual inspection of the prepared mold to verify its completeness and identify any potential issues.

2. Describe the process of pouring molten metal into the mold.

Safety Precautions:

- Confirm that all safety gear is in place (protective clothing, gloves, face shield, etc.).

- Ensure the work area is clear of obstacles and potential hazards.

Pouring Procedure:

- I receive the molten metal in a ladle from the melting furnace.

- Carefully pour the molten metal into the prepared mold, avoiding splashing or spills.

- Use a controlled flow rate to minimize turbulence and prevent air entrapment.

- Fill the mold completely, reaching the desired metal level.

- Monitor the pouring process and adjust the flow rate as needed.

3. How do you handle and store the solidified castings after they have cooled?

- Cooling: Allow the castings to cool gradually in a controlled environment to prevent cracking or warping.

- Knockout: Once cooled, I carefully knock out the castings from the mold using a vibrator or other appropriate methods.

- Inspection: I visually inspect the castings for any defects, such as cracks, porosity, or dimensional inconsistencies.

- Cleaning: I remove any remaining mold material, burrs, or protrusions from the castings.

- Storage: I store the cleaned castings in a designated area, protecting them from moisture, dust, or other environmental factors.

4. Explain the importance of maintaining a clean and organized work area as a Molder Helper.

- Safety: A clean and organized work area minimizes trip hazards, reduces the risk of accidents, and prevents injuries.

- Efficiency: Maintaining order allows for quick access to materials and tools, improving productivity.

- Quality: A clean work area helps prevent contamination of castings, ensuring their quality and minimizing defects.

- Mold Preparation: A tidy workspace facilitates efficient mold preparation, reducing the risk of errors or oversights.

- Professionalism: A well-organized work area reflects professionalism and attention to detail.

5. Describe your experience in using injection molding machines.

- Machine Setup: I am proficient in setting up injection molding machines, including selecting the appropriate parameters for the specific mold and material.

- Material Handling: I safely handle and prepare plastic materials for injection molding, ensuring proper feeding and melting.

- Molding Process: I monitor the molding process, ensuring that the molten plastic fills the mold cavities completely and that the cycle time is optimized.

- Part Ejection: I operate the part ejection system to remove molded parts from the machine and inspect them for defects.

- Troubleshooting: I am experienced in troubleshooting common issues with injection molding machines, such as flow problems, temperature variations, or mold alignment errors.

6. How do you prioritize your tasks and manage your time effectively in a fast-paced foundry environment?

- Task Prioritization: I assess the urgency and importance of tasks, prioritizing those that impact production or safety first.

- Time Management: I utilize time management techniques, such as creating a task list and setting deadlines, to stay organized and efficient.

- Collaboration: I communicate effectively with other team members to coordinate tasks and prevent overlaps or delays.

- Flexibility: I am adaptable to changing priorities and deadlines, adjusting my schedule and tasks as needed.

- Continuous Improvement: I regularly review my work processes and identify areas for improvement to enhance my efficiency.

7. Explain how you ensure the accuracy of measurements when working with molds and casting processes.

- Measurement Tools: I use calibrated measuring instruments, such as micrometers, calipers, and gauges, to ensure precise measurements.

- Verification: I double-check all measurements to minimize errors and maintain accuracy.

- Clear Communication: I communicate measurement results clearly and accurately to other team members involved in the casting process.

- Attention to Detail: I pay meticulous attention to measurement details, such as decimal places and unit conversions, to avoid mistakes.

- Industry Standards: I adhere to established industry standards and specifications when taking measurements.

8. Describe your experience in operating and maintaining overhead cranes and hoists in a foundry setting.

- Crane Operation: I am proficient in operating overhead cranes to safely lift and move materials, molds, and castings.

- Load Handling: I use proper rigging techniques and calculate load capacities to ensure safe and efficient handling.

- Crane Maintenance: I perform daily inspections and routine maintenance tasks on cranes and hoists, such as lubricating moving parts and checking for wear or damage.

- Safety Protocols: I strictly follow all safety protocols related to crane operation and maintenance, including load limits, hand signals, and lockout/tagout procedures.

- Troubleshooting: I am skilled in diagnosing and resolving minor crane or hoist issues, ensuring minimal downtime.

9. How do you handle and dispose of hazardous materials, such as chemical binders and solvents, in accordance with safety regulations?

- Material Identification: I properly identify and label hazardous materials according to their safety data sheets (SDS).

- Safe Handling: I wear appropriate personal protective equipment (PPE), such as gloves, respirator, and eye protection, when handling hazardous materials.

- Disposal Procedures: I follow established procedures for disposing of hazardous waste, ensuring compliance with environmental regulations.

- Spill Response: I am trained in spill response procedures and have the necessary equipment to contain and clean up spills safely.

- Safety Training: I regularly participate in safety training to stay updated on hazardous materials handling best practices.

10. Describe your knowledge and experience in using foundry software, such as CAD/CAM or simulation programs.

- CAD/CAM Proficiency: I am familiar with CAD/CAM software used for designing and creating patterns and molds.

- Simulation Software: I have experience using simulation programs to analyze casting processes, optimize mold designs, and predict potential defects.

- Software Integration: I understand how foundry software integrates with other systems, such as ERP or MES, for efficient production management.

- Continuous Learning: I am eager to learn and stay updated on the latest foundry software technologies and applications.

- Problem Solving: I use my software knowledge to solve technical challenges and improve foundry processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molder Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molder Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molder Helpers assist Molder in the production of molded products, such as plastic and metal parts. They perform a variety of tasks, including:

1. Prepare Molds

Molder Helpers prepare molds for casting by cleaning and lubricating them. They also ensure that the molds are properly aligned and leveled.

- Clean molds using solvents, brushes, or rags.

- Lubricate molds using oil, grease, or other lubricants.

- Align and level molds using levels, squares, or other tools.

2. Load and Unload Molds

Molder Helpers load and unload molds with molten metal or plastic. They use hoists, cranes, or other equipment to move the molds.

- Load molds with molten metal or plastic using hoists, cranes, or other equipment.

- Unload molds after the metal or plastic has cooled and solidified.

3. Inspect Molded Products

Molder Helpers inspect molded products for defects. They check for cracks, bubbles, or other imperfections. They also measure the products to ensure that they meet specifications.

- Inspect molded products for cracks, bubbles, or other defects.

- Measure molded products to ensure that they meet specifications.

4. Clean and Maintain Equipment

Molder Helpers clean and maintain equipment used in the molding process. They also perform minor repairs on equipment.

- Clean equipment using solvents, brushes, or rags.

- Lubricate equipment using oil, grease, or other lubricants.

- Perform minor repairs on equipment.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips:

1. Research the Company

Before your interview, take some time to research the company. This will help you understand their culture, values, and what they’re looking for in a Molder Helper. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, products, and services.

- Read the company’s social media pages to get a sense of their culture and values.

- Check out Glassdoor to see what other employees have to say about the company.

2. Practice Your Answers

Once you’ve done your research, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Think about your strengths and weaknesses.

- Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Practice your answers out loud to make sure you sound confident and articulate.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and pressed.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose clothes that are comfortable and that you feel confident in.

4. Be Yourself

The most important thing is to be yourself during your interview. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just be yourself and let your personality shine through.

- Be honest about your skills and experience.

- Share your passion for the molding industry.

- Be confident and enthusiastic.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molder Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!