Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molder so you can tailor your answers to impress potential employers.

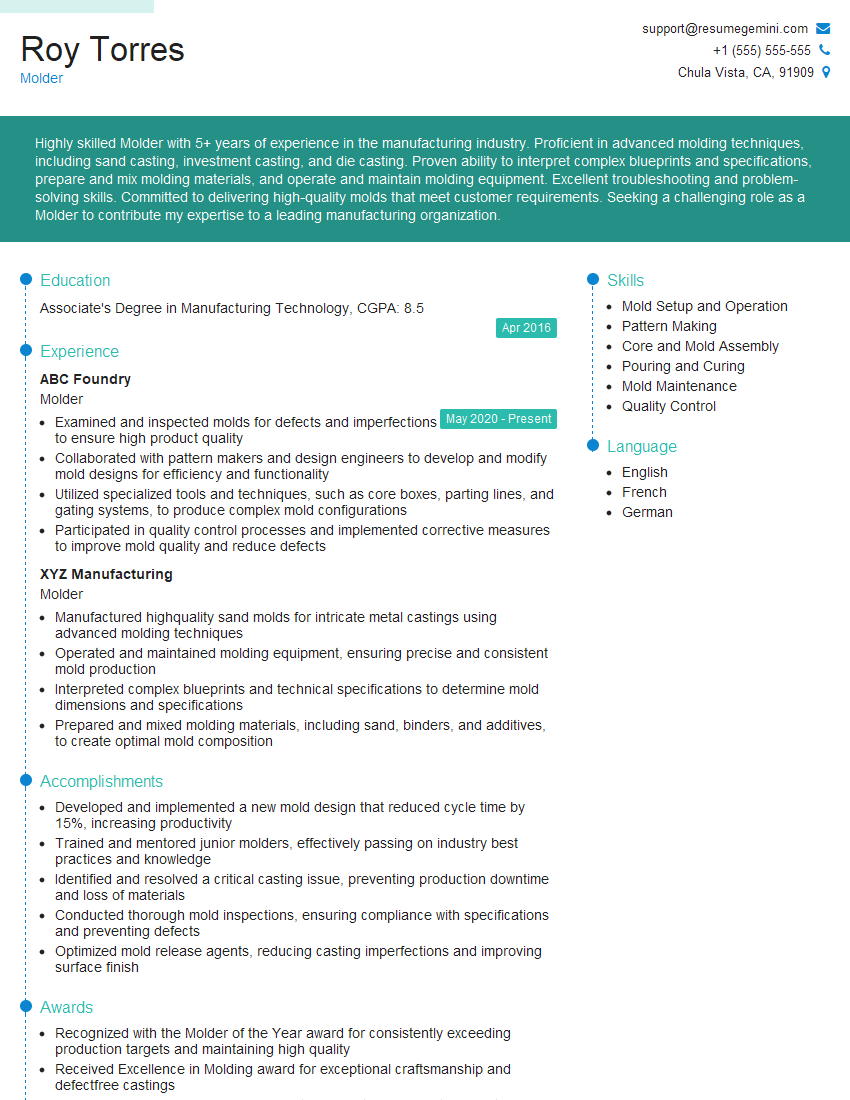

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molder

1. What are the key responsibilities of a Molder?

– Prepare and evaluate molds and cores for the production of metal castings. – Maintain and repair molds and cores, as necessary. – Inspect castings for defects and ensure that they meet specifications. – Follow safety regulations and maintain a clean and organized work area.

2. What are the different types of molding processes?

Sand Molding

- Green sand molding

- Dry sand molding

- Resin-bonded sand molding

Investment Molding

- Lost wax process

- Ceramic shell process

Die Casting

- Gravity die casting

- Pressure die casting

- Vacuum die casting

3. What are the important properties of molding materials?

- Refractoriness

- Permeability

- Strength

- Collapsibility

- Surface finish

4. What are the common defects in castings?

- Shrinkage porosity

- Gas porosity

- Misruns

- Cold shuts

- Cracks

5. How do you prevent defects in castings?

- Use the correct molding materials and processes.

- Control the pouring temperature and rate.

- Properly vent the mold.

- Allow the casting to cool slowly.

- Inspect the casting carefully before use.

6. What are the different types of mold releases?

- Oil-based mold releases

- Water-based mold releases

- Synthetic mold releases

7. How do you maintain and repair molds and cores?

- Inspect the molds and cores for damage.

- Repair any damage using the appropriate materials and techniques.

- Clean and lubricate the molds and cores.

- Store the molds and cores in a dry and dust-free environment.

8. What are the safety regulations that must be followed in a foundry?

- Wear appropriate personal protective equipment (PPE).

- Keep the work area clean and organized.

- Use caution when handling molten metal.

- Follow all safety procedures and instructions.

9. What are the different types of metal castings?

- Ferrous castings

- Non-ferrous castings

10. What are the advantages and disadvantages of casting?

Advantages

- Can produce complex shapes.

- Can produce parts with high strength and durability.

- Cost-effective for mass production.

Disadvantages

- Can be time-consuming and labor-intensive.

- Can produce defects if not done properly.

- Not suitable for all materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molders are responsible for shaping and forming molten metal, plastic, or other materials into various products. Their primary tasks include:

1. Mold Preparation

Preparing and setting up molds, ensuring proper alignment and functioning.

- Cleaning molds and removing debris.

- Applying mold release agents to prevent sticking.

2. Material Handling

Handling and pouring molten metal or materials into molds, ensuring accurate filling.

- Maintaining appropriate temperature and viscosity of molten materials.

- Controlling flow rate and pouring techniques to achieve desired product shapes.

3. Ejection and Finishing

Removing finished products from molds, inspecting for defects, and performing necessary finishing operations.

- Trimming excess material and smoothening edges.

- Performing quality checks to ensure product specifications are met.

4. Maintenance and Troubleshooting

Maintaining mold equipment, cleaning, and lubricating as required.

- Troubleshoot and identify any issues with mold operation or quality.

- Work with maintenance personnel to resolve complex problems.

Interview Tips

Preparing for a Molder interview requires a combination of technical knowledge, communication skills, and enthusiasm. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Demonstrate your interest and understanding of the company’s business, products, and industry trends. Research their website, LinkedIn profile, and recent news articles.

2. Highlight Your Technical Skills

Emphasize your proficiency in mold preparation, material handling, and ejection techniques. Mention specific equipment and materials you have worked with, and quantify your results whenever possible.

3. Showcase Your Problem-Solving Abilities

Discuss instances where you have successfully identified and resolved mold-related issues. Highlight your analytical thinking, troubleshooting skills, and ability to work under pressure.

4. Prepare Questions to Ask

Asking well-thought-out questions shows that you are engaged and interested in the position. Inquire about the company’s current projects, sustainability initiatives, or opportunities for professional development.

5. Practice Your Communication Skills

Molders often work in collaborative environments. Demonstrate your ability to communicate effectively with colleagues, supervisors, and customers. Use clear language and be confident in your responses.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately and arrive on time for your interview. Maintain a positive and professional demeanor throughout the interaction.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.