Are you gearing up for a career in Molding Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Molding Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

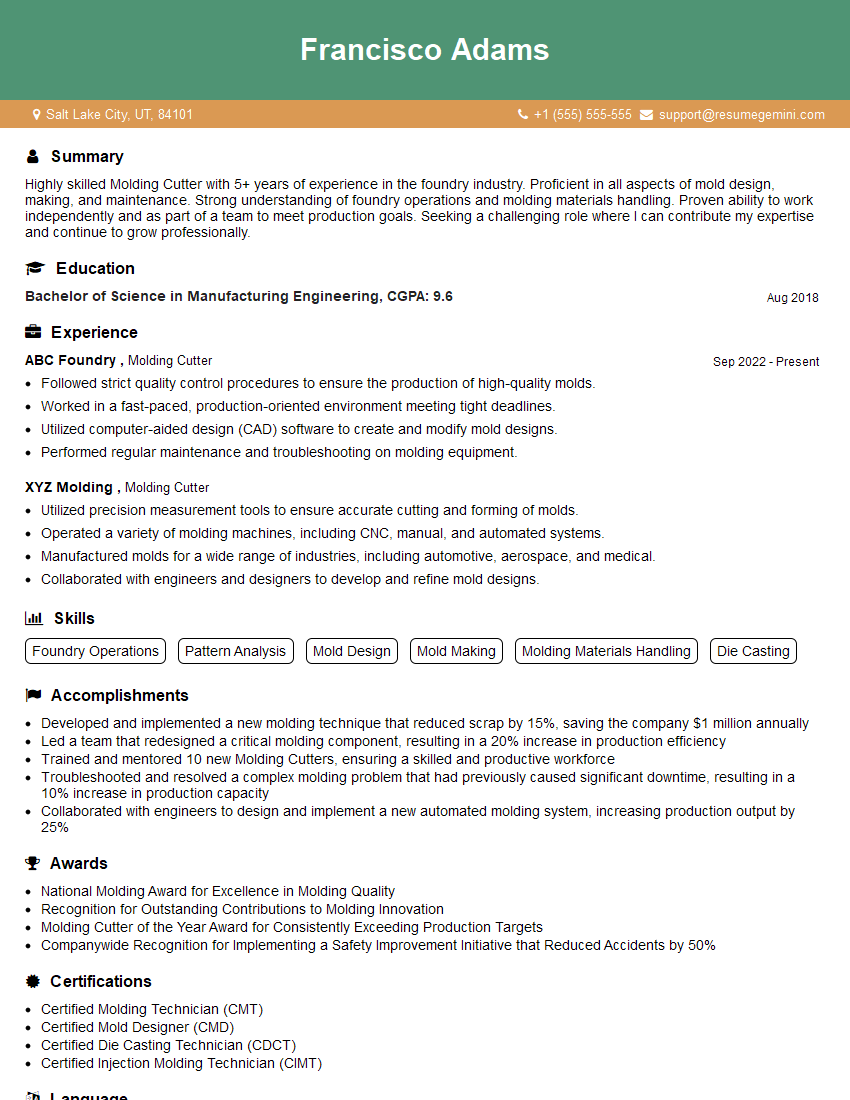

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Cutter

1. How do you ensure that the molding cutters meet the required specifications?

- Inspect the cutters with a micrometer and calipers to ensure that they are within tolerance.

- Test the cutters on a sample of material to verify that they cut cleanly and accurately.

- Maintain a record of all inspections and tests to track the quality of the cutters.

2. What are the different types of molding cutters and their applications?

End Mills: General-purpose cutters used for milling contours, slots, and pockets.

Side and Face Cutters: Used for milling flat surfaces and edges.

Ball Nose Cutters: Used for milling complex curves and surfaces.

Chamfer Cutters: Used for creating angled edges.

Dovetail Cutters: Used for cutting dovetail joints.

3. How do you sharpen a molding cutter to maintain its cutting edge?

Use a dedicated cutter grinder with a suitable abrasive wheel.

Maintain the correct grinding angle and wheel speed for the cutter material.

Use light passes and avoid overheating the cutter.

4. What are the safety precautions you observe when operating a molding cutter?

- Wear appropriate safety gear, including eye protection, gloves, and earplugs.

- Ensure that the cutter is securely mounted in the machine.

- Use a coolant or lubricant to reduce heat and friction.

- Avoid excessive feed rates that can cause chatter or breakage.

- Never reach into the cutting area while the machine is running.

5. How do you calculate the optimal feed rate for a molding cutter?

- Consider the cutter diameter, material, and number of flutes.

- Use a feed calculator or consult the manufacturer’s recommendations.

- Start with a conservative feed rate and gradually increase it while monitoring the cutting performance.

6. What are the common causes of molding cutter failure?

- Overheating due to excessive feed rates or lack of lubrication.

- Wear and tear from prolonged use.

- Improper sharpening or grinding.

- Incorrect mounting or alignment.

- Impact or damage caused by foreign objects.

7. How do you troubleshoot chatter or vibration during molding operations?

- Check for loose mounting or alignment.

- Reduce the feed rate or use a different cutter.

- Increase the spindle speed or use a coolant.

- Inspect the cutter for any damage or wear.

- Balance the workpiece to reduce vibration.

8. What are the different methods used to measure the sharpness of a molding cutter?

- Visual inspection: Check for any nicks, burrs, or wear on the cutting edges.

- Micrometer: Measure the cutter diameter and cutting edge radius.

- Microscope: Examine the cutting edge under a microscope to assess its sharpness and geometry.

9. How do you maintain the accuracy and precision of molding cutters?

- Regular sharpening to ensure optimal cutting performance.

- Calibration and inspection to verify conformity to specifications.

- Proper storage in a controlled environment to prevent corrosion and damage.

10. What are the latest advancements in molding cutter technology that enhance productivity?

Diamond-coated cutters: Longer tool life and reduced wear.

Micro-grain carbide cutters: Improved surface finish and reduced burrs.

3D printed cutters: Complex geometries and customization.

Automated optimization software: Optimized feed rates and tool paths.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Cutters are responsible for operating molding machines to produce plastic or rubber components. They work in manufacturing environments and operate machines that use molds to shape and form materials. Their key responsibilities include:

1. Machine Operation

Molding Cutters are responsible for setting up, operating, and maintaining molding machines. They follow established procedures and ensure that machines are operating safely and efficiently. They may also perform minor repairs and adjustments on machines.

- Set up and operate molding machines according to specifications.

- Monitor machine performance and make necessary adjustments.

- Perform routine maintenance and troubleshooting on machines.

2. Molding Process

Molding Cutters are responsible for ensuring that the molding process is carried out according to specifications. They monitor the flow of materials, temperature, and pressure during the molding process.

- Monitor the molding process and make adjustments as needed.

- Inspect molded parts for defects and take corrective action.

- Maintain a clean and organized work area.

3. Quality Control

Molding Cutters are responsible for ensuring that the quality of molded parts meets customer specifications. They inspect parts for defects, dimensions, and other quality characteristics. They also work with quality control personnel to identify and resolve any quality issues.

- Inspect molded parts for defects and dimensions.

- Work with quality control personnel to identify and resolve quality issues.

- Implement corrective actions to prevent defects.

4. Safety and Environmental Compliance

Molding Cutters are responsible for adhering to safety and environmental regulations. They follow established procedures for the safe operation of machines and the handling of hazardous materials. They also ensure that the work area is clean and free of hazards.

- Follow established safety procedures.

- Handle hazardous materials according to regulations.

- Maintain a clean and hazard-free work area.

Interview Tips

Preparing for an interview for a Molding Cutter position can be a daunting task. However, by following these tips and tricks, you can increase your chances of making a great impression and landing the job.

1. Research the Company and Position

Before you go on an interview, it’s important to do your research on the company and the position. This will help you understand the company’s culture, values, and what they are looking for in a Molding Cutter. You can find this information on the company’s website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, mission, and values.

- Check out the company’s social media pages to get a sense of their culture and what it’s like to work there.

- Read reviews on Glassdoor to get insights into the interview process and what it’s like to work at the company.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked in an interview for a Molding Cutter position. By practicing your answers to these questions, you can increase your confidence and deliver polished and well-thought-out responses. Some common interview questions include:

- Tell me about your experience operating molding machines.

- How do you ensure that the quality of molded parts meets customer specifications?

- What are some of the challenges you have faced in your previous role as a Molding Cutter?

- How do you stay up-to-date on the latest molding technologies?

- What are your strengths and weaknesses as a Molding Cutter?

3. Be Prepared to Talk About Your Safety Experience

Safety is a top priority in manufacturing environments. In your interview, you will likely be asked about your safety experience and how you would ensure the safety of yourself and others in the workplace. Be prepared to discuss your knowledge of safety regulations, your experience with safety equipment, and your commitment to following safety procedures.

- Discuss your knowledge of OSHA regulations and other relevant safety standards.

- Describe your experience with using safety equipment, such as gloves, goggles, and earplugs.

- Explain how you would ensure the safety of yourself and others in the workplace.

4. Dress Professionally and Arrive on Time

First impressions matter. When you go on an interview for a Molding Cutter position, it’s important to dress professionally and arrive on time. This shows the interviewer that you are serious about the job and that you respect their time.

- Wear clean and pressed business attire.

- Arrive on time for your interview.

- Be polite and respectful to the interviewer and other staff members.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Molding Cutter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Molding Cutter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.