Are you gearing up for a career in Molding Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Molding Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

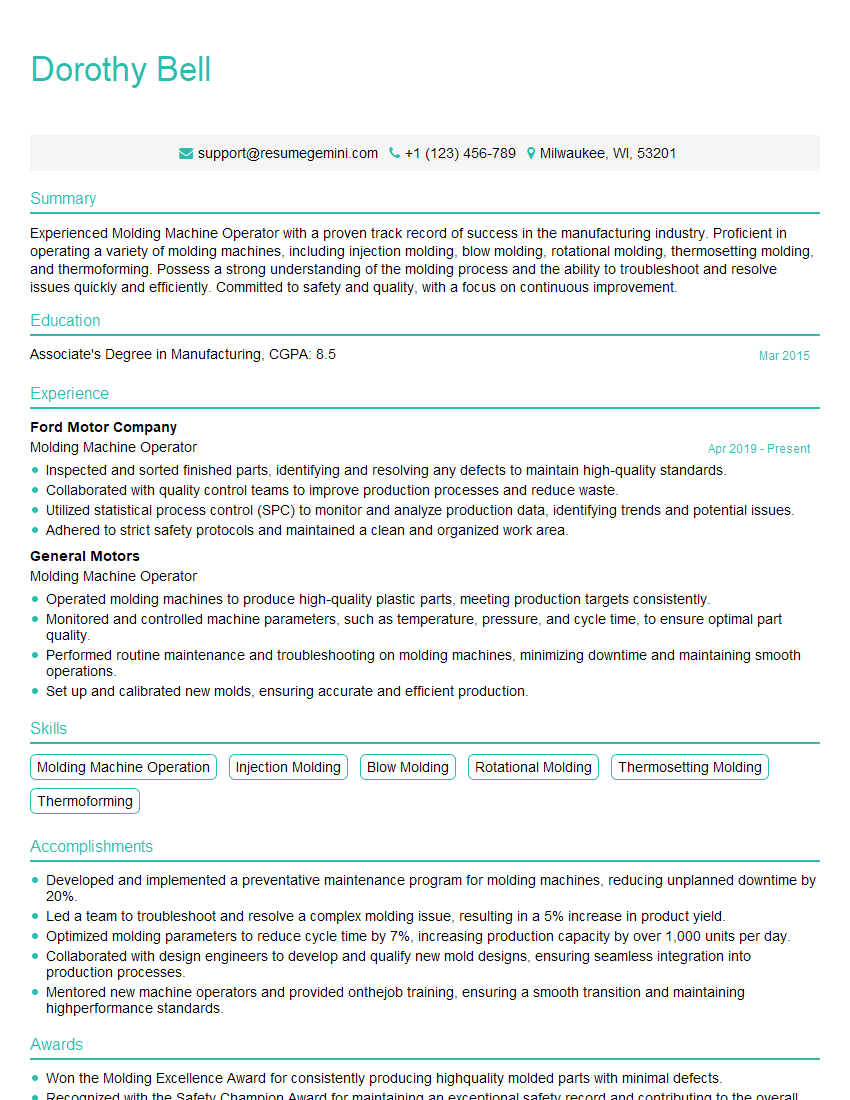

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Machine Operator

1. Explain the process of setting up a molding machine for a new mold?

- Review the mold specifications and determine the appropriate machine settings.

- Clean the mold and apply release agent.

- Install the mold into the machine and secure it properly.

- Adjust the mold temperature and pressure settings.

- Conduct a test run to verify the mold settings and make any necessary adjustments.

2. Describe the different types of molding defects and how to troubleshoot them?

Mold Flash:

- Cause: Excessive pressure or temperature, incorrect mold alignment.

- Solution: Adjust pressure or temperature, inspect mold for alignment.

Air Traps:

- Cause: Incomplete mold filling, entrapped air.

- Solution: Increase injection speed or pressure, vent the mold.

Flow Lines:

- Cause: Uneven flow of material, improper mold design.

- Solution: Adjust injection speed or temperature, modify mold design.

3. How do you ensure the quality of molded parts?

- Conduct regular inspections of parts.

- Use quality control tools such as gauges and measuring equipment.

- Follow established quality standards and procedures.

- Monitor machine parameters and make adjustments as needed.

- Provide feedback to the production team to improve quality.

4. How do you maintain and troubleshoot molding machines?

- Perform regular inspections and maintenance checks.

- Identify and resolve minor issues before they escalate.

- Troubleshoot complex problems using diagnostic tools and manuals.

- Coordinate with maintenance technicians for repairs or replacements.

- Maintain a clean and organized work area.

5. What safety precautions do you follow when operating a molding machine?

- Wear appropriate PPE (gloves, safety glasses, hearing protection).

- Never reach into the mold area while the machine is running.

- Keep the work area clear of obstructions.

- Follow established safety protocols and procedures.

- Be aware of the potential hazards and take steps to mitigate risks.

6. How do you calculate the cycle time for a molding machine?

- Identify the individual steps involved in the molding cycle.

- Determine the time required to complete each step.

- Add up the individual times to calculate the total cycle time.

- Consider factors such as machine speed, mold complexity, and material properties.

- Optimize the cycle time by adjusting machine parameters and improving efficiency.

7. What factors affect the quality of a molded part?

- Mold design and condition.

- Material properties and selection.

- Machine settings (temperature, pressure, cycle time).

- Process control and monitoring.

- Environmental conditions.

8. How do you optimize the performance of a molding machine?

- Fine-tune machine settings for specific materials and molds.

- Use data collection tools to monitor and analyze machine performance.

- Identify areas for improvement and implement changes.

- Collaborate with the production team and engineers to optimize processes.

- Follow industry best practices and attend training programs.

9. Describe your experience with different types of molding machines?

- List the specific types of molding machines you have operated.

- Describe the key features and capabilities of each machine type.

- Highlight your proficiency in operating and troubleshooting different machines.

10. How do you stay updated on the latest molding technologies and industry trends?

- Attend industry events and conferences.

- Read technical journals and publications.

- Participate in online forums and networking groups.

- Consult with experts and seek training opportunities.

- Stay informed about new materials, processes, and equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Machine Operators are essential in manufacturing industries, where they play a crucial role in shaping and forming materials into desired products. Here are some key responsibilities of a Molding Machine Operator:1. Machine Operation

Operate and maintain molding machines, including setting up, adjusting, and troubleshooting

Monitor machine performance, quality of molded parts, and make necessary adjustments to ensure efficiency

Clean and maintain machines to ensure optimal performance and prevent breakdowns

2. Mold Preparation and Setup

Inspect and prepare molds, ensuring they are clean and in good working order

Install molds into molding machines and align them precisely

Perform mold changeovers efficiently to minimize downtime

3. Material Handling

Load and unload raw materials into the molding machine

Monitor material flow and adjust settings to achieve desired product quality

Inspect molded parts for defects and remove any excess material

4. Quality Assurance

Inspect molded parts for dimensions, tolerances, and surface finish

Identify and address any defects or non-conformances

Maintain quality records and report any issues promptly

5. Safety and Maintenance

Adhere to safety regulations and protocols in the workplace

Perform routine maintenance checks on molding machines and report any issues

Participate in safety training and follow proper lockout/tagout procedures

Interview Preparation Tips

To ace the interview for a Molding Machine Operator position, it is essential to prepare thoroughly. Here are some effective tips:1. Research the Company and Role

Research the company’s website, LinkedIn page, and industry news to gain an understanding of their products, culture, and values.

Read the job description carefully and identify the key responsibilities and qualifications required for the role.

2. Highlight Relevant Skills and Experience

In your resume and interview answers, emphasize your skills and experience that align with the job requirements.

Quantify your accomplishments whenever possible to demonstrate the impact of your work.

For example, instead of saying “operated molding machines,” you could say “Operated molding machines, resulting in a 15% increase in production efficiency.”

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this role?” and “What are your strengths and weaknesses?”

Structure your answers using the STAR method (Situation, Task, Action, Result).

For example, when answering “Why are you interested in this role?”, you could say: “I am excited about the opportunity to join your team because I am passionate about precision manufacturing. My experience in operating molding machines, coupled with my commitment to quality and efficiency, makes me confident that I can contribute to the success of your organization.”

4. Be Prepared to Discuss Safety

Molding Machine Operators must adhere to strict safety protocols. Be prepared to discuss your understanding of safety procedures, such as lockout/tagout, and how you ensure a safe working environment.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the role and the company.

For example, you could ask about the company’s approach to quality control, or about opportunities for professional development within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Molding Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Molding Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.