Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molding Machine Setter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molding Machine Setter so you can tailor your answers to impress potential employers.

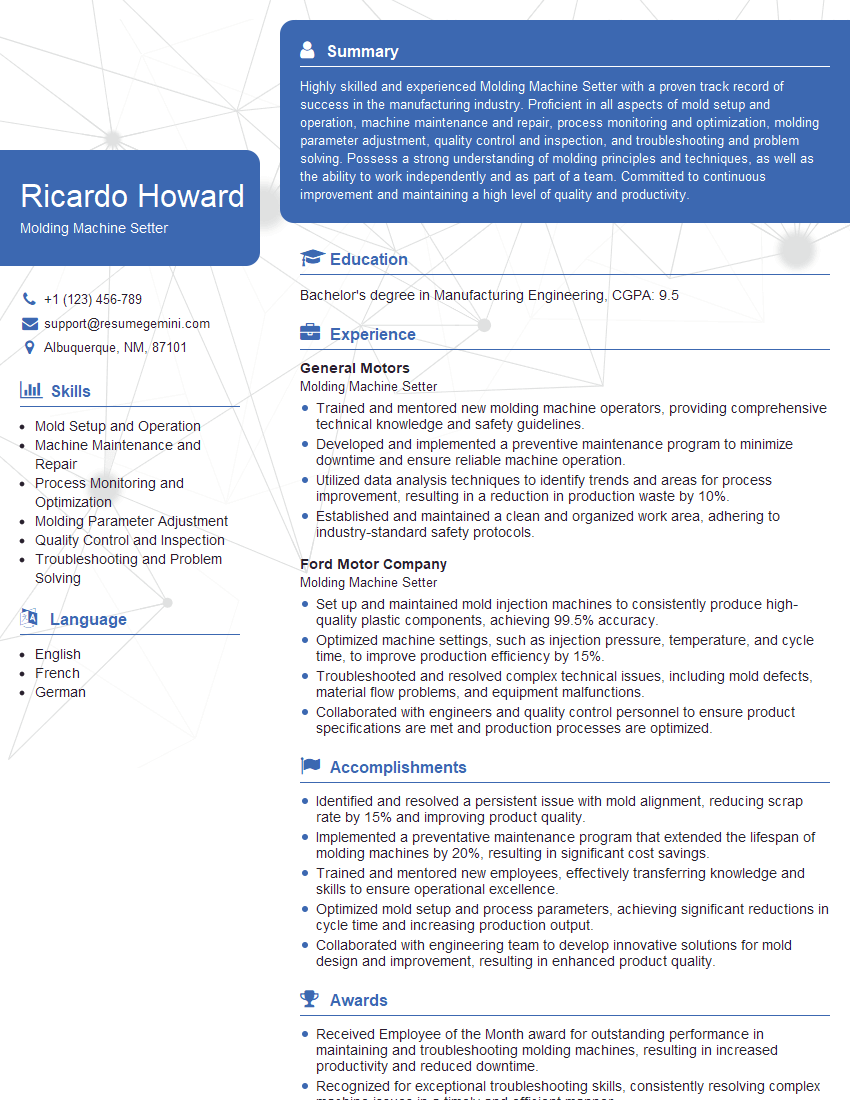

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Machine Setter

1. Describe the process of setting up and operating a molding machine.

In molding machine setup and operation, several key steps are involved:

- Mold Selection and Preparation: Select the appropriate mold for the desired part, ensuring its proper dimensions and cleanliness.

- Machine Configuration: Adjust the machine’s settings, including temperature, pressure, and cycle time, based on the mold and material specifications.

- Material Loading: Load the raw material into the machine’s hopper and verify its flow and distribution.

- Mold Mounting and Alignment: Mount the mold securely onto the machine and ensure precise alignment between the molding surfaces.

- Cycle Initiation and Monitoring: Start the molding cycle and closely monitor the process, including pressure, temperature, and cycle time.

- Part Ejection: Once the molding cycle is complete, eject the molded part from the mold and inspect it for quality.

2. How do you troubleshoot common molding machine problems, such as incorrect part dimensions or poor surface finish?

Identifying the Root Cause

- Incorrect Part Dimensions: Check mold dimensions, material flow, clamping pressure, and machine settings.

- Poor Surface Finish: Examine mold cleanliness, material quality, injection pressure, and mold temperature.

Troubleshooting Solutions

- Incorrect Part Dimensions: Adjust mold dimensions, improve material flow, increase clamping pressure, or recalibrate machine settings.

- Poor Surface Finish: Clean the mold, use higher-quality material, adjust injection pressure, or optimize mold temperature.

3. What maintenance tasks are required to keep a molding machine running smoothly?

- Regular Cleaning: Clean the mold, machine surfaces, and injection nozzles to prevent contamination and ensure proper operation.

- Mold Inspection: Inspect molds for wear, damage, or misalignment, and address any issues promptly.

- Hydraulic and Electrical Maintenance: Check hydraulic lines, electrical connections, and sensors for leaks or malfunctions, and perform necessary repairs or replacements.

- Lubrication: Lubricate moving parts and joints according to the manufacturer’s recommendations to reduce friction and wear.

- Calibration: Regularly calibrate the machine’s sensors and settings to ensure accuracy and optimal performance.

4. How do you calculate the appropriate molding parameters, such as injection pressure and cycle time, for a given material and mold?

- Material Properties: Determine the flow characteristics, viscosity, and temperature sensitivity of the molding material.

- Mold Dimensions and Complexity: Consider the part geometry, wall thickness, and mold features that influence flow and cooling.

- Machine Capabilities: Check the machine’s specifications for maximum pressure, temperature, and cycle time limits.

- Empirical Data: Refer to previous molding experience or industry standards to establish initial parameter values.

- Fine-tuning: Adjust parameters incrementally during production and monitor part quality to optimize the process.

5. What quality control measures do you implement to ensure the production of high-quality molded parts?

- Incoming Material Inspection: Verify the quality and specifications of incoming raw materials.

- Mold Inspection: Regularly inspect molds for damage, wear, or misalignment that can affect part quality.

- Process Monitoring: Monitor molding parameters, such as pressure, temperature, and cycle time, to detect any deviations from optimal settings.

- Part Inspection: Conduct visual inspections and dimensional measurements to ensure parts meet specifications.

- Statistical Process Control: Implement statistical techniques, such as SPC charts, to track process performance and identify areas for improvement.

6. How do you optimize the efficiency of a molding machine to reduce production costs?

- Molding Parameter Optimization: Fine-tune molding parameters to minimize cycle time and material waste.

- Automated Material Handling: Implement automated systems to reduce manual labor and improve material flow efficiency.

- Preventive Maintenance: Regular maintenance helps prevent breakdowns and ensures consistent machine performance.

- Operator Training: Provide proper training to operators to optimize machine utilization and reduce errors.

- Production Scheduling: Optimize production schedules to minimize machine downtime and maximize capacity utilization.

7. How do you handle challenging materials, such as high-temperature polymers or reinforced plastics?

- Material Research: Research the properties and molding characteristics of challenging materials.

- Specialized Molding Equipment: Use specialized molding machines designed to handle high temperatures or reinforced plastics.

- Process Modifications: Adjust molding parameters, such as temperature profiles and cooling strategies, to accommodate specific material requirements.

- Experience and Expertise: Gain experience and develop expertise in working with challenging materials to achieve desired results.

8. What safety precautions do you take when working with molding machines?

- Machine Guarding: Ensure that all machine guards are in place and functioning properly.

- Personal Protective Equipment: Wear appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection.

- Lockout/Tagout Procedures: Follow established lockout/tagout procedures when performing maintenance or repairs.

- Hot Surface Awareness: Be aware of hot surfaces on the machine and handle parts carefully to prevent burns.

- Emergency Response: Know the emergency response procedures and have necessary equipment, such as fire extinguishers, readily available.

9. How do you stay up-to-date with the latest advancements in molding technology?

- Industry Publications: Read industry publications and magazines to learn about new technologies.

- Conferences and Trade Shows: Attend industry conferences and trade shows to connect with experts and learn about the latest innovations.

- Online Resources: Utilize online forums, webinars, and technical articles to stay informed.

- Collaboration with Suppliers: Engage with equipment suppliers and material manufacturers to discuss new technologies and developments.

- Internal Knowledge Sharing: Share knowledge and best practices with colleagues to foster continuous improvement.

10. What is your understanding of the role of a Molding Machine Setter in a manufacturing environment?

Job Responsibilities:

- Set up, operate, and maintain molding machines to produce high-quality plastic parts.

- Troubleshoot and resolve machine malfunctions to ensure efficient production.

- Monitor molding parameters and make adjustments as needed to optimize the process.

- Conduct quality control checks to ensure parts meet specifications.

- Maintain a clean and organized work area to promote safety and efficiency.

Core Competencies:

- Thorough understanding of molding machine operation and setup.

- Ability to identify and resolve common molding problems.

- Strong mechanical aptitude and problem-solving skills.

- Attention to detail and commitment to producing high-quality parts.

- Teamwork and communication skills to collaborate with operators and supervisors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Molding Machine Setter, you will be responsible for ensuring the efficient and safe operation of molding machines. Your key responsibilities will include:

1. Machine Setup and Maintenance

Set up, adjust, and maintain molding machines to ensure optimal performance

- Configure machine parameters, including pressure, temperature, and cycle times

- Inspect machines regularly for wear and tear; perform necessary repairs and replacements

2. Mold Installation and Removal

Install and remove molds on molding machines accurately and safely

- Use hoists and other equipment to maneuver heavy molds

- Ensure proper alignment and sealing of molds

3. Material Handling

Handle and load raw materials into molding machines efficiently

- Operate forklifts or conveyors to transport materials

- Monitor material levels and ensure consistent feeding into machines

4. Quality Control

Inspect molded products for defects and ensure they meet quality standards

- Use measuring tools, gauges, and other equipment to verify product dimensions

- Identify and correct any deviations from specifications

5. Safety and Procedures

Follow established safety protocols and maintain a clean and organized work environment

- Wear appropriate personal protective equipment (PPE)

- Adhere to company policies and procedures for machine operation and maintenance

Interview Tips

To ace the interview for a Molding Machine Setter position, follow these tips:

1. Research the Company and Position

Show your interest in the company and the role by researching their background, industry, and specific job requirements.

- Highlight how your skills and experience align with the company’s goals and the responsibilities of the position.

2. Showcase Your Technical Skills

Emphasize your knowledge and experience in molding machine operation, setup, and maintenance.

- Provide specific examples of your ability to troubleshoot and resolve machine issues.

- Discuss your experience with different types of molding machines and materials.

3. Highlight Your Safety and Quality Standards

Demonstrate a strong commitment to safety and quality.

- Describe your experience with implementing and following safety protocols.

- Share examples of how you have ensured product quality and met specifications.

4. Prepare for Common Interview Questions

Be prepared to answer questions related to your experience, skills, and motivation.

- Example Question: “Describe a time you had to troubleshoot a complex machine issue.”

- Example Question: “How do you ensure the accuracy and quality of molded products?”

5. Ask Thoughtful Questions

Ask questions that demonstrate your interest in the position and the company.

- Example Question: “What is the company’s approach to continuous improvement in molding processes?”

- Example Question: “Can you describe the opportunities for professional development and career growth within the organization?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Molding Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.