Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Molding Plasterer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

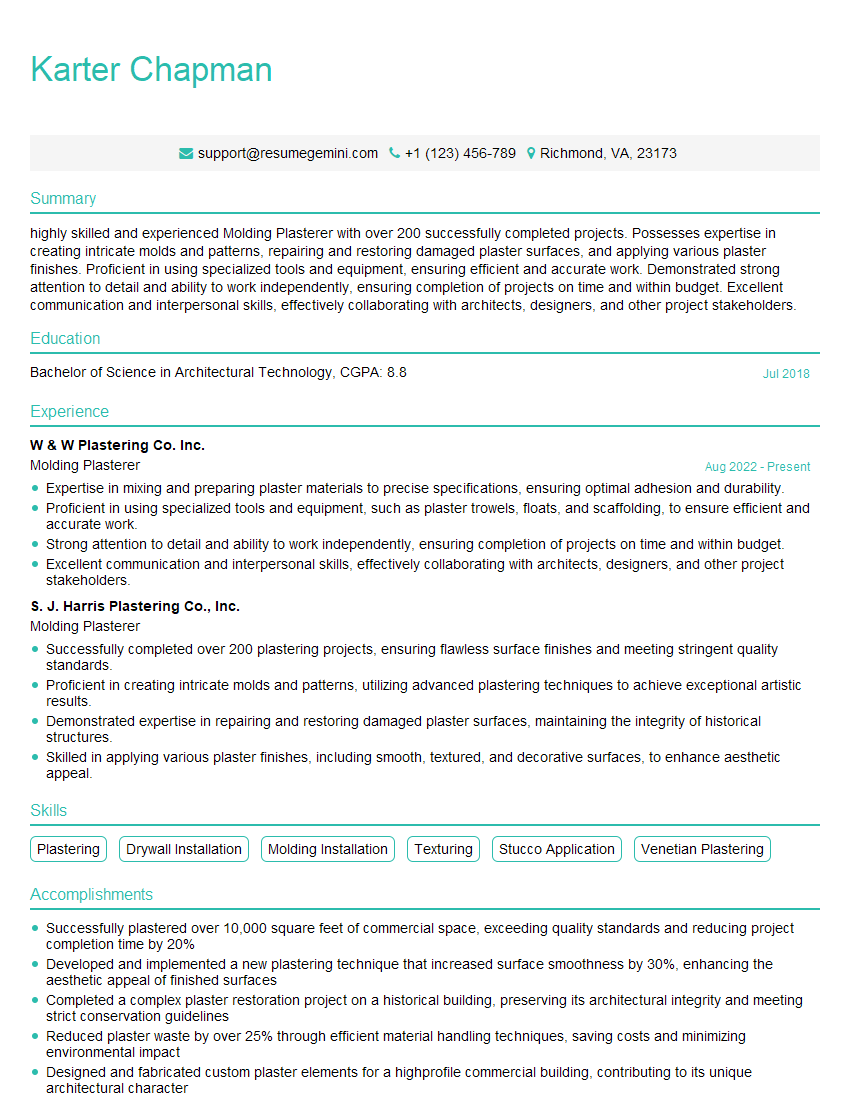

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Plasterer

1. Explain the process of creating a mold for plaster casting?

Creating a mold for plaster casting involves several steps:

- Prepare the Original: Protect the surface of the original object with a release agent and create a mold box around it.

- Make the Mother Mold: Apply a flexible material, such as silicone or latex, over the original and allow it to set.

- Make the Supporting Mold: Create a rigid outer support structure, typically made of plaster, to reinforce the mother mold.

- Separate the Molds: Carefully separate the mother mold and supporting mold, revealing the negative mold of the original object.

2. What are the different types of plaster used in molding and their properties?

There are three main types of plaster used in molding:

- Gypsum Plaster: The most common type, made from calcium sulfate, offering good strength and fire resistance.

- Hydrocal Plaster: A fast-setting plaster, made from calcium sulfate with added chemicals, resulting in a smoother finish.

- Dental Plaster: A high-strength plaster, used in dental applications, providing a very fine and detailed finish.

3. Describe the techniques for casting plaster into a mold?

Casting plaster into a mold involves several techniques:

- Pouring: Holding the mold steady, pour the mixed plaster into the mold and gently tap to release air bubbles.

- Vibrating: Placing the mold on a vibrating table or using a hand-held vibrator to remove air bubbles and ensure a solid cast.

- Pressure Casting: Applying pressure to the plaster in the mold using a vacuum or pressure casting system to achieve a denser and more uniform cast.

4. How do you ensure the accuracy and detail of the final casting?

To ensure accuracy and detail in the final casting:

- Use a High-Quality Mold: Create a precise and detailed mold to capture the features of the original.

- Mix the Plaster Properly: Follow the manufacturer’s instructions to achieve the correct consistency and minimize air bubbles.

- Cast Method: Choose the appropriate casting technique (pouring, vibrating, or pressure casting) to suit the mold and desired results.

- Remove the Casting Carefully: Once the plaster has set, carefully remove it from the mold to avoid damage.

5. What are the common defects that can occur in plaster casting and how to prevent them?

Common defects in plaster casting include:

- Air Bubbles: Prevent by vibrating or using a vacuum system during casting.

- Insufficient Curing: Ensure the plaster cures properly to achieve full strength.

- Cracking: Avoid by using a strong supporting mold and controlling the casting conditions.

- Warping: Prevent by using a well-reinforced mold and casting on a flat surface.

6. Describe the techniques for finishing and coloring plaster castings?

Finishing and coloring plaster castings involve:

- Smoothing: Remove any imperfections using sandpaper or abrasive sponges.

- Sealing: Apply a sealant to protect the casting from moisture and stains.

- Coloring: Use paints, stains, or glazes to add color and enhance the aesthetics of the casting.

7. How do you maintain and calibrate the tools used in molding plaster?

To ensure accuracy and safety:

- Inspect Regularly: Check tools for wear, damage, or misalignment.

- Clean and Lubricate: Keep tools clean and lubricated for optimal performance.

- Calibrate: Use precise measuring tools to calibrate equipment such as vibrating tables and pressure casting systems.

8. What safety precautions should be taken while working with plaster?

For safety:

- Wear Protective Gear: Use gloves, dust masks, and eye protection to prevent exposure to dust.

- Ventilate Well: Ensure proper ventilation to avoid inhaling plaster dust.

- Dispose Properly: Follow regulations for disposing of plaster waste and debris.

- Avoid Skin Contact: Prolonged contact with wet plaster can cause skin irritation.

9. Describe the different methods for creating decorative moldings and their applications?

Creating decorative moldings involves:

- Plaster Carving: Hand-carving plaster to create intricate designs.

- Molding and Casting: Using molds to produce detailed moldings.

- Run Casting: Creating continuous moldings by pouring plaster into a moving mold.

- Stamping and Pressing: Using molds or stamps to imprint patterns or textures onto plaster.

10. How do you stay updated with the latest techniques and materials used in plaster molding?

To stay informed:

- Attend Workshops and Training: Participate in industry events to learn new techniques.

- Read Trade Publications: Subscribe to magazines and journals for industry updates.

- Network with Professionals: Connect with other molders and stay informed about best practices.

- Research and Experiment: Explore new materials and techniques to expand your skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Plasterer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Plasterer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Plasterers, also known as Stucco Masons, specialize in the application and finishing of molded plaster and various other architectural decorative elements. Their primary duty involves transforming raw materials into intricate and visually appealing designs that adorn architectural structures and interiors.

1. Casting and Installation of Architectural Elements

Molding Plasterers are highly skilled craftsmen who possess the expertise to create moldings, cornices, and various other decorative components from plaster, gypsum, and other similar materials. They commence the process by preparing the molds, and then they meticulously pour and cast the plaster into these molds. Once the plaster sets, they skillfully remove the casts from the molds and proceed with meticulous sanding and finishing to achieve a smooth and flawless surface.

- Construct architectural elements, such as cornices, moldings, and decorative plasterwork, from blueprints and design specifications

- Mix and pour plaster or cement into molds to create decorative elements

2. Repairs and Restoration of Existing Structures

Molding Plasterers play a vital role in preserving historical and architectural heritage by expertly repairing and restoring damaged or deteriorated plasterwork. They meticulously assess the condition of existing structures, carefully matching the original materials and techniques to seamlessly blend their repairs with the surrounding architecture. This delicate and specialized work requires a deep understanding of traditional plasterwork and a commitment to maintaining the integrity of the original design.

- Repair cracks, chips, and other damage to plaster surfaces

- Restore damaged or deteriorated plasterwork to match the original design and materials

3. Application of Finishes and Textures

Molding Plasterers are masters of their craft when it comes to applying a diverse array of finishes and textures to plaster surfaces. They possess the expertise to create smooth, textured, or ornamental finishes, employing various application techniques and tools to achieve the desired aesthetic effect. This meticulous attention to detail elevates the visual appeal of architectural elements, transforming them into captivating works of art.

- Apply various finishes to plaster surfaces, such as smooth, textured, or ornamental finishes

- Use different application techniques and tools to achieve desired effects

4. Collaboration and Communication

Molding Plasterers work collaboratively with architects, designers, and other construction professionals to ensure that their work aligns with the overall design vision. They actively participate in project planning and execution, providing valuable insights and expertise to contribute to the success of the project. Effective communication and coordination are crucial to maintaining a harmonious working environment and achieving optimal results.

- Collaborate with architects, designers, and other construction professionals to ensure that work meets design specifications

- Communicate effectively with clients and other stakeholders to keep them informed of progress and any issues

Interview Tips

Preparing for an interview can be nerve-racking, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview for a Molding Plasterer position:

1. Research the Company and the Position

Take the time to thoroughly research the company you are applying to and the specific position you are interested in. Familiarize yourself with their history, values, and the industry they operate in. This knowledge will demonstrate your interest in the company and help you tailor your answers to match their needs.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers to Common Interview Questions

There are certain interview questions that are commonly asked in almost every interview. By preparing your answers to these questions in advance, you can build your confidence and deliver articulate and well-thought-out responses during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with molding and plasterwork?

3. Highlight Your Skills and Experience

Be sure to highlight your skills and experience that are relevant to the position you are applying for. Use specific examples to demonstrate your abilities and how you have applied them in your previous roles. Quantify your accomplishments whenever possible to provide concrete evidence of your impact.

- Emphasize your experience in casting and installing architectural elements.

- Showcase your skills in repairing and restoring plasterwork.

- Highlight your ability to apply a variety of finishes and textures.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Show the interviewer that you are genuinely interested in the position and that you are confident in your abilities. Be respectful of the interviewer’s time and answer their questions honestly and succinctly.

- Dress professionally and arrive on time for your interview.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be prepared to ask questions at the end of the interview.

Next Step:

Now that you’re armed with the knowledge of Molding Plasterer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Molding Plasterer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini