Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Molding Process Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

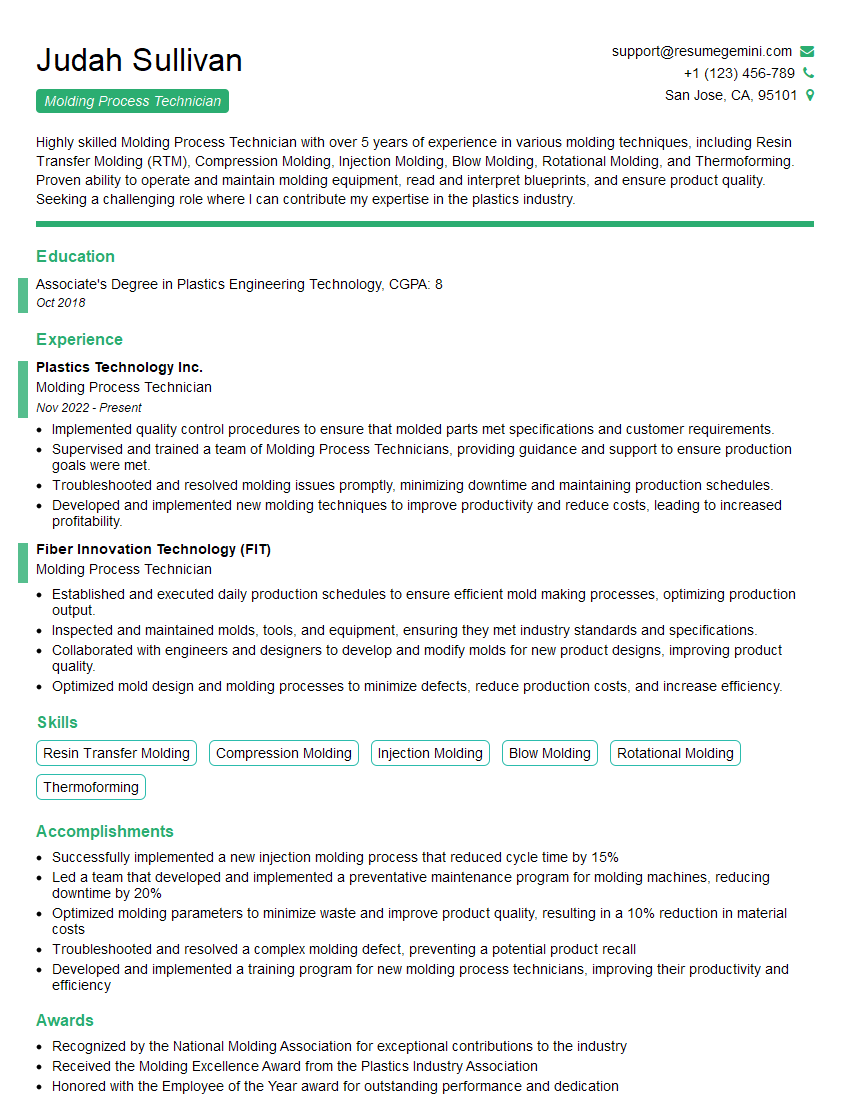

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Process Technician

1. Describe the steps involved in the molding process.

The molding process typically involves the following steps:

- Preparing the mold by cleaning and applying a release agent.

- Mixing the molding material according to the manufacturer’s instructions.

- Pouring the molding material into the mold.

- Allowing the molding material to cure.

- Removing the finished molding from the mold.

2. What are the different types of molding materials?

Thermoplastics

- Can be repeatedly melted and solidified without changing their chemical composition.

- Examples include polyethylene, polypropylene, and polystyrene.

Thermosets

- Undergo a chemical change when heated, making them permanently hard and infusible.

- Examples include epoxy, polyester, and phenolic resins.

Elastomers

- Exhibit rubber-like properties, such as flexibility and elasticity.

- Examples include natural rubber, synthetic rubber, and silicone.

3. What are the factors that affect the quality of a molded part?

The quality of a molded part is influenced by several factors, including:

- The type and quality of the molding material.

- The condition of the mold.

- The molding process parameters (e.g., temperature, pressure, time).

- The skill and experience of the molding technician.

4. How do you troubleshoot common molding defects?

Common molding defects include:

- Flash: Excess material that forms around the edges of the molding.

- Sink: A depression in the surface of the molding.

- Warp: A distortion in the shape of the molding.

- Voids: Air bubbles trapped in the molding.

Troubleshooting these defects involves identifying the root cause and adjusting the molding process parameters accordingly.

5. What are the safety hazards associated with the molding process?

The molding process involves several potential hazards, including:

- Exposure to hazardous chemicals.

- Risk of burns from hot materials.

- خطر الإصابة بجروح من معدات حادة.

- Eye injuries from flying particles.

- Respiratory problems from inhaling fumes and dust.

It is important to follow proper safety procedures to minimize these risks.

6. What are the key quality control measures for molded parts?

Quality control measures for molded parts include:

- Visual inspection for defects.

- Dimensional measurement to ensure accuracy.

- Mechanical testing to assess strength and durability.

- Statistical process control to monitor and improve process quality.

7. What are the different types of mold release agents?

Mold release agents are used to prevent the molding material from sticking to the mold. Different types of mold release agents include:

- Silicone-based: Non-toxic and easy to apply, but can contaminate the molding material.

- Hydrocarbon-based: Inexpensive and effective, but can leave a residue on the molding.

- Wax-based: Less likely to contaminate the molding material, but can be more difficult to apply.

- Fluorinated-based: High-performance release agents that are expensive but effective.

8. What are the advantages of using a vacuum forming machine?

Vacuum forming machines offer several advantages, including:

- Low tooling costs: Molds are inexpensive and easy to produce.

- Fast production: Parts can be produced quickly and efficiently.

- Design flexibility: Complex shapes can be easily produced.

9. What are the different types of curing ovens?

Curing ovens are used to harden and cure molding materials. Different types of curing ovens include:

- Convection ovens: Use heated air to circulate around the molding material.

- Induction ovens: Use electromagnetic fields to heat the molding material.

- Microwave ovens: Use microwaves to heat the molding material.

- Ultraviolet ovens: Use ultraviolet light to cure the molding material.

10. What are the emerging trends in the molding industry?

Emerging trends in the molding industry include:

- Increased use of automation: To improve efficiency and reduce costs.

- Development of new materials: With improved properties and performance.

- Integration of additive manufacturing: To create complex and customized parts.

- Emphasis on sustainability: To reduce environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Process Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Process Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Process Technicians are responsible for operating and maintaining molding machines to manufacture products from various materials. Their key responsibilities include:

1. Machine Operation

Operate molding machines to produce plastic or rubber parts according to specifications.

- Set up and adjust molding machines, including mold installation and removal.

- Monitor machine operation and make adjustments to ensure quality and efficiency.

2. Mold Maintenance

Perform routine maintenance and repairs on molding machines and related equipment.

- Inspect molds and equipment for wear and tear, and replace or repair as needed.

- Lubricate and clean machines to maintain optimal performance.

3. Material Handling

Handle and prepare raw materials for molding processes.

- Measure and mix materials according to specifications.

- Load raw materials into molding machines.

4. Quality Control

Inspect finished products for defects and ensure they meet quality standards.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Identify and report any errors or defects to supervisors.

Interview Tips

To ace an interview for a Molding Process Technician position, candidates should be prepared to demonstrate their technical skills and knowledge, as well as their commitment to safety and quality.

1. Research the Company and Industry

Learn about the company’s history, products, and industry reputation. This will help you understand their business operations and align your qualifications with their needs.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Highlight Your Technical Skills

Emphasize your experience operating and maintaining molding machines. Be prepared to discuss your troubleshooting abilities and how you ensure product quality.

- Provide specific examples of how you have resolved machine problems.

- Quantify your results whenever possible, using metrics such as increased production efficiency or reduced downtime.

3. Demonstrate Your Safety and Quality Mindset

Molding processes involve potential hazards and quality requirements. Highlight your commitment to safety and quality by discussing your experience with safety protocols and quality control procedures.

- Explain how you ensure proper machine operation and maintenance to prevent accidents.

- Describe your experience using quality control methods to inspect products and identify defects.

4. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to molding processes, machine operation, and quality control. Practice speaking clearly and confidently.

- Example Question: Describe your experience troubleshooting a molding machine malfunction.

- Example Question: How do you prioritize quality control in your work?

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving for your interview on time. This demonstrates your professionalism and respect for the company.

Next Step:

Now that you’re armed with the knowledge of Molding Process Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Molding Process Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini