Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Molding Sander position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

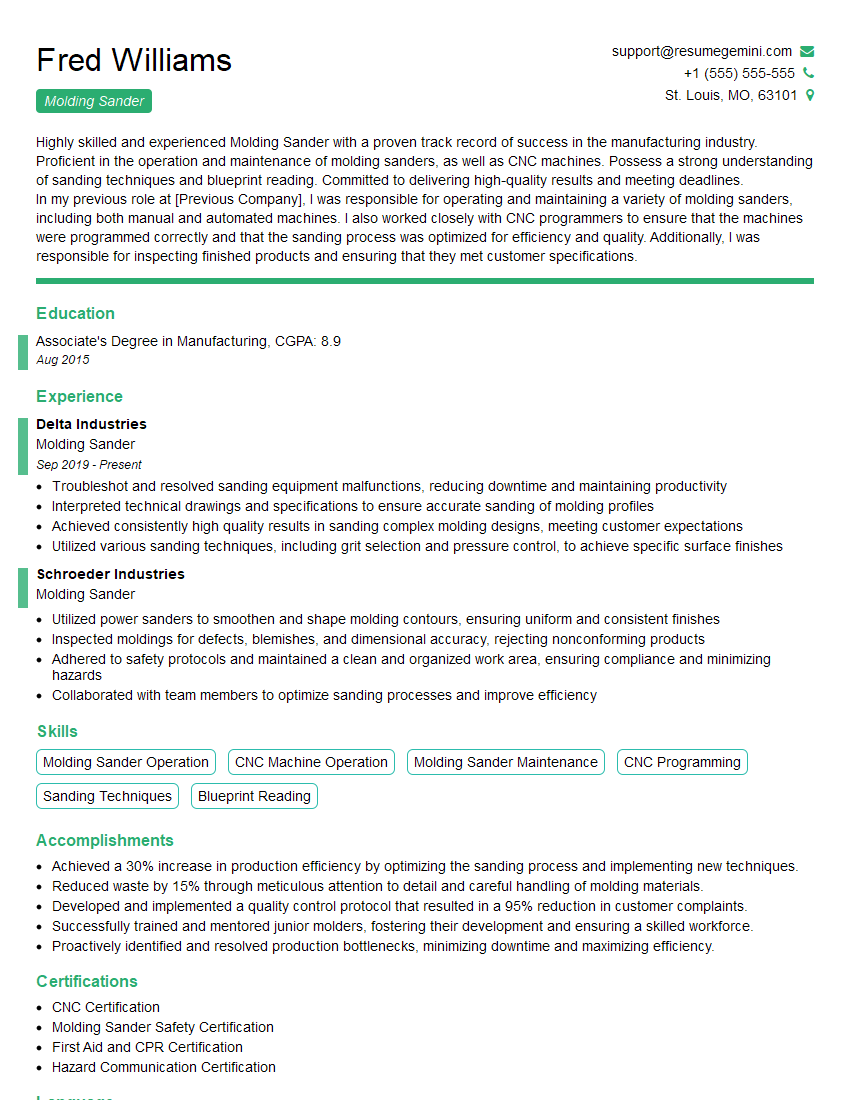

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Sander

1. What are the typical duties and responsibilities of a molding sander?

As a molding sander, my responsibilities typically include:

- Smoothing and shaping the edges of molding using a sanding machine

- Sanding different types of materials like wood, metal, and plastic

- Reading blueprints and specifications to understand molding requirements

- Operating various types of sanding machines including edge sanders and belt sanders

- Performing quality checks to ensure that molding meets the desired finish standards

2. What safety precautions should be taken when operating a sanding machine?

- Always wear proper safety gear like gloves, eye protection, and a mask to prevent exposure to dust and debris

- Ensure that the machine is properly grounded and in good working condition

- Secure the molding firmly in place before sanding to prevent it from moving and causing accidents

- Inspect the sanding belts and replace them if worn or damaged

- Keep the work area clean and free of dust and debris to prevent tripping hazards

3. How do you determine the appropriate grit size for sanding different types of molding?

The grit size of the sanding belt depends on the material of the molding and the desired finish:

- For rough sanding and removing imperfections, I use a coarser grit like 80 or 120

- For smoothing the surface and preparing it for paint or stain, I use a medium grit like 150 or 220

- For a fine finish and removing any remaining scratches, I use a finer grit like 320 or 400

4. What techniques do you use to achieve precise and consistent sanding results?

- I make sure to use a light and even touch when operating the sanding machine

- I follow the contours of the molding to avoid creating uneven surfaces

- I use a guide or jig to ensure consistency in sanding

- I frequently check the progress and make adjustments to the sanding speed or pressure as needed

5. How do you troubleshoot common problems that may occur while using a sanding machine?

- If the machine vibrates excessively, I check the belts for damage and ensure that they are properly tensioned

- If the sanding belt tears, I replace it immediately to prevent further damage

- If the motor overheats, I stop using the machine and allow it to cool down before continuing

- If the dust collection system is not working properly, I clean the filter or bag and check for any blockages

6. What maintenance procedures do you perform to keep sanding machines in optimal condition?

- I regularly clean the machine to remove dust and debris

- I lubricate moving parts as per the manufacturer’s recommendations

- I inspect the belts, cords, and other components for wear or damage

- I follow the manufacturer’s guidelines for maintenance intervals and repairs

7. How do you interpret technical drawings and specifications for molding sanding?

I carefully review the drawings and specifications to understand the dimensions, profiles, and finish requirements of the molding:

- I identify the type of molding, its shape, and its dimensions

- I determine the desired finish and select the appropriate sanding grits and techniques

- I check for any special instructions or notes that may affect the sanding process

8. What quality control procedures do you follow to ensure that sanded molding meets the required standards?

- I visually inspect each piece of molding after sanding to check for any unevenness, scratches, or defects

- I use measuring tools to verify the dimensions and ensure that the molding meets the specified tolerances

- I compare the sanded molding to a standard sample or template to assess the quality of the finish

9. How do you prioritize multiple sanding tasks and manage your time effectively?

I prioritize tasks based on their urgency and importance:

- I focus on completing critical tasks with tight deadlines first

- I break down large tasks into smaller, manageable chunks

- I use a scheduling tool or planner to keep track of my tasks and deadlines

10. How do you stay updated on the latest industry trends and best practices in molding sanding?

- I attend industry conferences and workshops to learn about new technologies and techniques

- I read trade publications and technical manuals to stay informed about industry advancements

- I connect with other molding sanders and professionals to share knowledge and experiences

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Sander.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Sander‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Sanders are responsible for finishing wood products by sanding and smoothing the surfaces. They use a variety of sanding tools and techniques to achieve the desired results.

1. Preparing the Work Area

Molding Sanders must first prepare the work area by ensuring that it is well-ventilated and free of dust. They must also gather the necessary tools and materials, including sandpaper, sanding blocks, and a dust mask.

2. Sanding the Workpieces

Molding Sanders use a variety of sanding tools and techniques to smooth and finish wood products. They may use hand-held sanding blocks or power sanders, depending on the size and shape of the workpiece.

3. Finishing the Workpieces

Once the workpieces have been sanded, Molding Sanders must finish them by applying a sealant or finish. This will help to protect the wood and give it a smooth, polished appearance.

4. Maintaining the Equipment

Molding Sanders must maintain their equipment in good working order. This includes cleaning and lubricating the sanding tools, and replacing sandpaper as needed.

Interview Tips

Preparing for an interview for a Molding Sander position can be daunting, but there are several things you can do to increase your chances of success.

1. Research the Company and the Position

Take some time to learn about the company you are applying to and the specific position you are interested in. This will help you to understand the company’s culture and the Anforderungen des Jobs.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “What are your strengths and weaknesses?” Practice answering these questions so that you can deliver your responses confidently and clearly.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the position and the company. Prepare a few thoughtful questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” or “What is the company’s culture like?”

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally and arrive on time for your interview. This will show the interviewer that you are respectful of their time and that you are serious about the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Molding Sander role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.