Are you gearing up for a career in Molding Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Molding Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

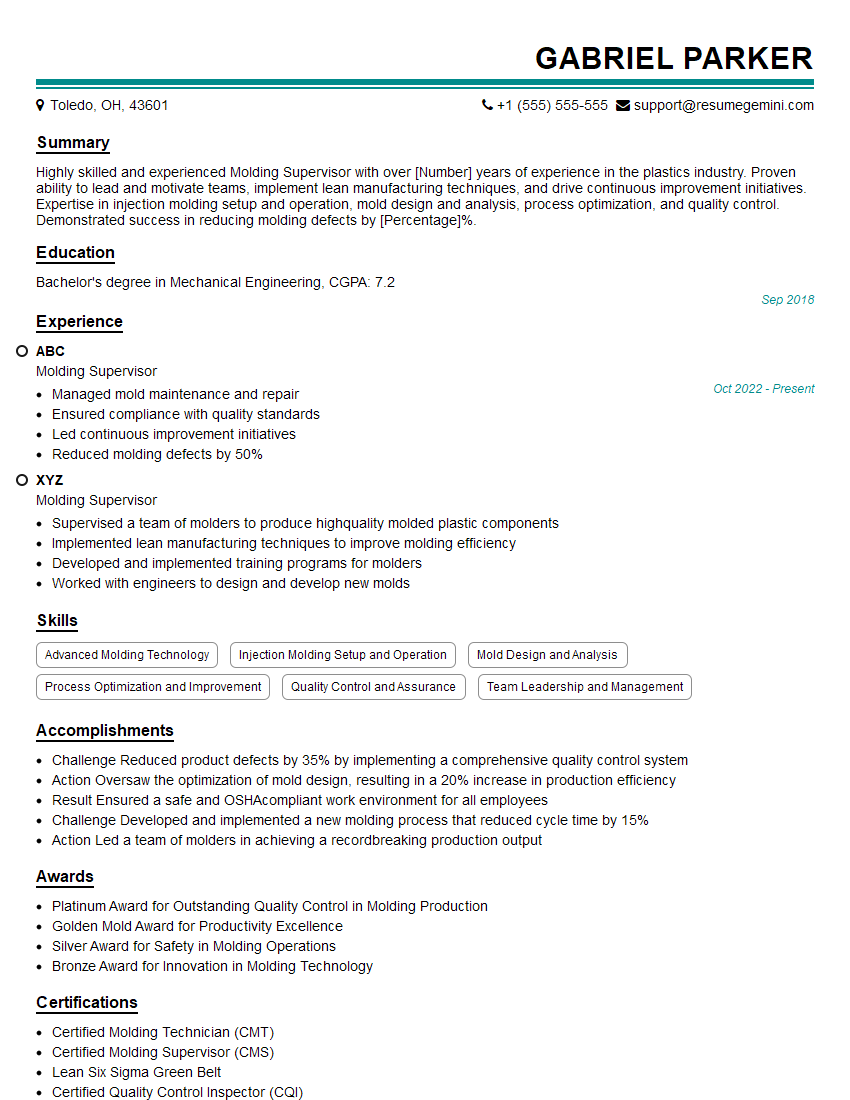

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Supervisor

1. Which molding processes are you familiar with?

As a Molding Supervisor, I am well-versed in various molding processes, including:

- Injection molding: Expertise in setting up and operating injection molding machines to produce high-volume plastic parts.

- Blow molding: Proficient in using blow molding machines to create hollow plastic products with complex shapes.

- Extrusion molding: Familiar with the extrusion process for producing continuous profiles, such as pipes, tubes, and films.

- Compression molding: Experience in the compression molding technique for manufacturing composite materials and rubber products.

- Casting molding: Knowledgeable in the casting process for creating metal or plastic parts by pouring molten material into a mold.

2. Describe your experience in mold design and optimization.

Understanding of Mold Design

- Proficient in using CAD software (e.g., SolidWorks, Creo) to design and modify molds.

- Strong knowledge of mold components, such as gates, runners, and cooling systems.

- Understanding of mold materials and their properties.

Optimization Techniques

- Familiar with mold flow analysis techniques to optimize mold design for efficient filling and cooling.

- Experience in using DOE (Design of Experiments) to improve mold performance and reduce defects.

- Knowledge of mold maintenance and troubleshooting techniques.

3. How do you ensure the quality and consistency of molded products?

Maintaining quality and consistency in molded products is crucial, and I implement several measures:

- Process Control: Establishing and adhering to standardized operating procedures (SOPs).

- Quality Inspection: Conducting regular inspections at various stages of the molding process using appropriate equipment and techniques.

- Statistical Process Control (SPC): Utilizing statistical tools to monitor and analyze production data to identify and address any variations.

- Corrective and Preventive Actions (CAPA): Implementing measures to address non-conforming products and prevent their recurrence.

- Collaboration: Working closely with production staff, engineers, and quality control teams to identify and resolve any issues that may affect product quality.

4. What are your strategies for increasing production efficiency in a molding operation?

To enhance production efficiency, I employ various strategies:

- Process Optimization: Analyzing and improving molding parameters, such as cycle times, temperature settings, and pressure levels.

- Automation and Robotics: Implementing automation solutions to reduce manual labor and increase throughput.

- Preventive Maintenance: Establishing a comprehensive maintenance schedule to prevent unplanned downtime and ensure smooth production.

- Employee Training: Investing in employee training to enhance their skills and knowledge, leading to increased productivity.

- Performance Monitoring and Improvement: Regularly monitoring production metrics and implementing continuous improvement initiatives to identify and address bottlenecks.

5. Describe your experience in managing a team of molding operators.

Leadership and Motivation

- Providing clear instructions and guidance to team members.

- Motivating and empowering the team to achieve high performance.

- Creating a positive and supportive work environment.

Training and Development

- Providing ongoing training and development to enhance the skills and knowledge of team members.

- Identifying and addressing areas for improvement to foster professional growth.

Performance Management

- Setting clear performance expectations and providing regular feedback.

- Conducting performance evaluations to recognize and reward achievements.

- Implementing performance improvement plans when necessary.

6. How do you handle equipment malfunctions and production issues in a molding operation?

In the event of equipment malfunctions or production issues, I follow a systematic approach:

- Immediate Response: Promptly assessing the situation and taking appropriate actions to minimize downtime.

- Problem Identification: Thoroughly investigating the issue to identify the root cause.

- Solution Implementation: Developing and implementing effective solutions to resolve the issue and prevent recurrence.

- Communication and Coordination: Keeping relevant stakeholders informed about the situation and coordinating efforts to address the issue.

- Documentation and Analysis: Documenting the incident, including the cause, corrective actions taken, and lessons learned to improve future response.

7. What is your approach to safety management in a molding operation?

Safety is paramount, and I adhere to the following principles:

- Compliance and Regulations: Ensuring compliance with all applicable safety regulations and standards.

- Training and Awareness: Providing comprehensive safety training to all employees and raising awareness about potential hazards.

- Hazard Identification and Risk Assessment: Identifying potential hazards and assessing risks to implement appropriate control measures.

- Incident Reporting and Investigation: Encouraging reporting and thoroughly investigating all incidents to identify and address safety concerns.

- Continuous Improvement: Regularly reviewing and updating safety protocols to improve workplace safety.

8. How do you stay updated with the latest advancements in molding technologies?

To stay abreast of industry developments, I actively engage in:

- Industry Events and Conferences: Attending industry events and conferences to learn about new technologies, best practices, and innovations.

- Technical Publications and Journals: Reading industry publications, journals, and research papers to keep up with the latest advancements.

- Online Resources and Webinars: Utilizing online resources, webinars, and manufacturer websites to access information on new products and technologies.

- Collaboration with Suppliers and Partners: Building relationships with suppliers and industry partners to gain insights into emerging technologies.

9. How do you ensure effective communication and collaboration with other departments within the organization?

Effective communication and collaboration are crucial. I prioritize:

- Regular Meetings and Communication Channels: Establishing regular meetings and utilizing communication channels to share information, updates, and address issues.

- Open and Transparent Communication: Fostering an environment where open and honest communication is encouraged.

- Collaboration on Projects: Actively participating in cross-functional projects to contribute and gather perspectives from different departments.

- Building Relationships: Building strong relationships with key individuals in other departments to facilitate collaboration and support.

10. What are your strengths and weaknesses as a Molding Supervisor?

Strengths

- Technical Expertise: Strong technical knowledge and skills in molding processes, mold design, and quality control.

- Leadership and Management: Proven ability to lead and motivate teams, manage production operations, and drive continuous improvement.

- Problem-Solving and Decision-Making: Excellent problem-solving abilities and a proactive approach to decision-making.

- Communication and Collaboration: Effective communication skills and experience in collaborating with diverse stakeholders.

Weaknesses

- New Technologies: Willingness to embrace new technologies, but may require additional training in specific areas.

- External Vendor Management: Limited experience in managing external vendors for specialized molding services.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Supervisors play a pivotal role in the manufacturing process, overseeing and managing the production of molded products. Their primary responsibilities include:

1. Production Management

- Plan, schedule, and assign production tasks to molding operators, ensuring efficient workflow and meeting production targets.

- Monitor production processes, identify bottlenecks and implement corrective measures to optimize production.

2. Quality Control

- Inspect molded products for defects and ensure compliance with quality standards.

- Develop and implement quality control systems to minimize errors and maintain product integrity.

3. Equipment Maintenance and Operation

- Ensure proper maintenance and operation of molding equipment, including presses, molds, and ancillary systems.

- Identify and resolve equipment malfunctions promptly to prevent production delays.

4. Team Management

- Lead, motivate, and train molding operators to improve performance and efficiency.

- Foster a positive and productive work environment, ensuring team members are well-informed and engaged.

Interview Tips

To ace the Molding Supervisor interview, it’s crucial to thoroughly prepare and demonstrate your skills and experience. Here are some interview tips to help you stand out:

1. Research the Company and Position

Thoroughly research the company’s background, industry, and product line. Study the job description and identify specific responsibilities and qualifications required for the role.

2. Highlight Your Relevant Skills

Emphasize your technical expertise in molding processes, including understanding of mold design, material properties, and quality control techniques. Showcase your leadership and management skills, such as team motivation, conflict resolution, and performance appraisal.

3. Quantify Your Achievements

Provide concrete examples of your accomplishments and quantify your results whenever possible. Use specific metrics to demonstrate how you improved production efficiency, reduced defects, or enhanced team performance.

4. Practice Common Interview Questions

Practice answering common interview questions related to molding supervision, such as:

- Describe your experience in managing molding operations, including production planning and quality control.

- What strategies have you implemented to improve production efficiency and reduce waste?

- How do you handle conflicts within your team and motivate your team members to achieve goals?

- What are the latest developments in molding technology and how do you stay updated on industry trends?

5. Showcase Your Passion and Drive

Convey your passion for molding supervision and highlight your commitment to delivering high-quality products. Express your enthusiasm for problem-solving and your dedication to continuous improvement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molding Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!