Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Molding Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Molding Technician so you can tailor your answers to impress potential employers.

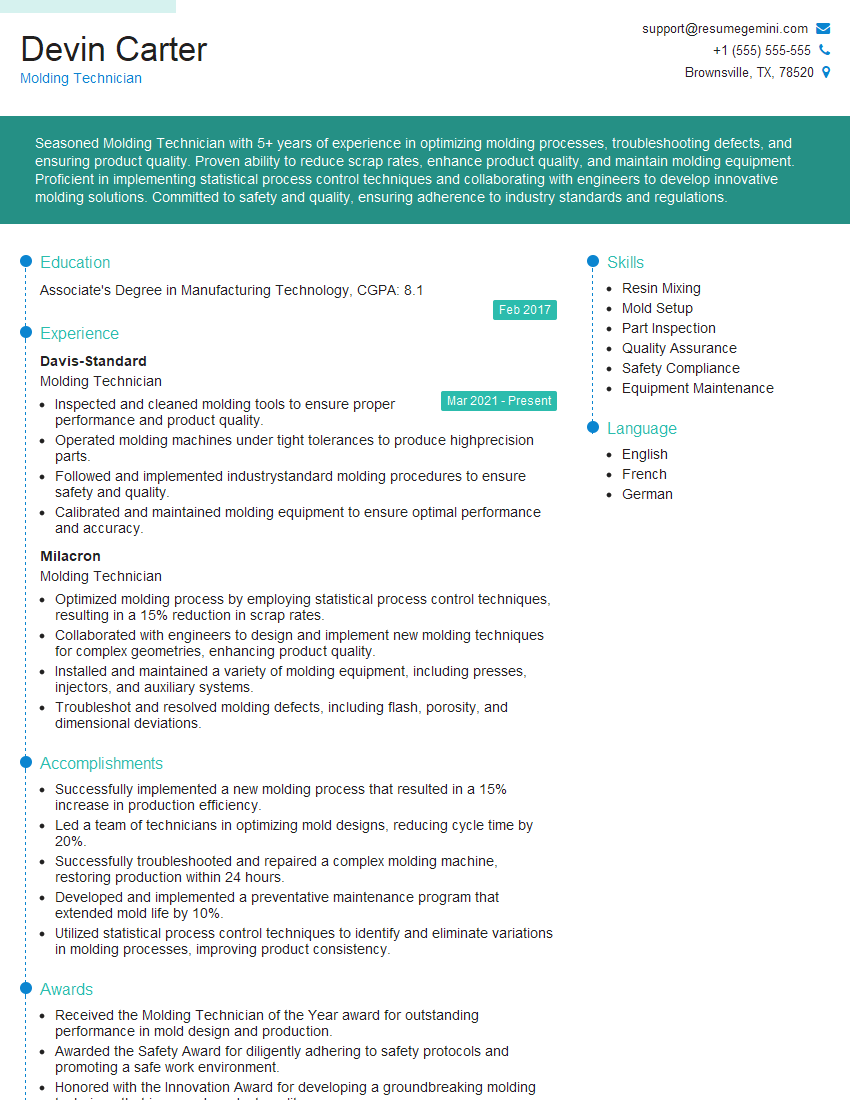

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molding Technician

1. Describe the steps involved in the molding process.

The molding process typically involves the following steps:

- Pattern making: Creating a physical or digital model of the desired part.

- Mold making: Creating a mold or cavity using the pattern.

- Material preparation: Mixing and preparing the molding material.

- Molding: Pouring or injecting the molding material into the mold.

- Curing: Allowing the molding material to set and harden.

- Demolding: Removing the finished part from the mold.

- Post-processing: Performing any necessary finishing operations, such as trimming, sanding, or painting.

2. Explain the different types of molding processes and their applications.

Injection molding

- High-volume production of complex parts with tight tolerances.

- Suitable for plastics, metals, and ceramics.

Compression molding

- High-pressure molding of thermosetting materials.

- Used for electrical components, automotive parts, and rubber products.

Transfer molding

- Combination of injection and compression molding.

- Produces high-precision parts with complex geometries.

3. How do you ensure the quality of molded parts?

Quality assurance measures for molded parts include:

- Visual inspection for defects, such as cracks, voids, or surface imperfections.

- Dimensional measurements to verify compliance with specifications.

- Testing for mechanical properties, such as strength, hardness, and impact resistance.

- Non-destructive testing, such as ultrasonic or X-ray inspection, to detect internal defects.

4. What are the common problems encountered in molding and how do you troubleshoot them?

Common molding problems include:

- Defects: Cracks, voids, surface imperfections.

- Dimensional inaccuracies: Incorrect part size or shape.

- Material issues: Improper material mixing, contamination.

- Molding equipment malfunctions: Faulty temperature control, injection pressure issues.

Troubleshooting steps involve analyzing the problem, identifying the root cause, and implementing corrective actions.

5. Describe the importance of mold maintenance and how it affects the quality of molded parts.

Mold maintenance is crucial for:

- Preventing defects and ensuring part quality.

- Extending mold life and reducing downtime.

- Maintaining dimensional accuracy and surface finish.

Mold maintenance includes cleaning, lubrication, and repairs to prevent wear and damage.

6. How do you optimize molding parameters to improve part quality and efficiency?

Molding parameter optimization involves:

- Adjusting injection pressure, temperature, and cycle time.

- Optimizing material flow rates and gate locations.

- Using simulation software to predict and optimize molding conditions.

Optimization aims to reduce defects, improve part consistency, and increase production efficiency.

7. Explain the role of temperature and pressure control in the molding process.

Temperature control

- Ensures proper material flow and solidification.

- Affects part quality, strength, and dimensional stability.

Pressure control

- Controls the material flow and packing pressure.

- Affects part density, strength, and surface finish.

8. What are the different types of molding materials and their properties?

Plastics

- Thermoplastics: Meltable and moldable, can be reused.

- Thermosets: Irreversible chemical change after molding, stronger than thermoplastics.

Metals

- Excellent strength and durability.

- Require special molding techniques, such as die casting or investment casting.

Ceramics

- High temperature resistance and electrical insulation.

- Brittle and difficult to mold.

9. Explain the principles of mold design and how it affects the molding process.

Mold design considerations include:

- Part geometry and tolerances.

- Material properties and molding process.

- Gating and venting systems.

Proper mold design ensures optimal material flow, reduces defects, and facilitates mold maintenance.

10. How do you stay up-to-date on the latest advancements in molding technologies?

To stay current on molding advancements:

- Attend industry conferences and workshops.

- Read technical journals and books.

- Network with other molding professionals.

- Research new materials, processes, and equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molding Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molding Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Molding Technicians play a crucial role in the manufacturing industry, ensuring the smooth production of molded products. Their key responsibilities include:

1. Mold Setup and Operation

Molding Technicians set up and operate molding machines, ensuring optimal performance and product quality.

- Prepare molds and molding machines for production runs.

- Monitor machine settings and make adjustments as needed.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

2. Material Handling and Processing

They handle and process molding materials, ensuring proper mixing and handling.

- Weigh and mix raw materials according to specified formulations.

- Load molds with materials and monitor the molding process.

- Remove molded products from molds and inspect them for defects.

3. Quality Control and Inspection

Molding Technicians inspect molded products to ensure they meet quality standards.

- Check products for dimensional accuracy, surface finish, and other specifications.

- Identify and report defective products for rework or disposal.

- Participate in quality improvement programs to enhance production processes.

4. Equipment Maintenance and Troubleshooting

They perform basic maintenance and troubleshooting on molding equipment.

- Clean and lubricate molding machines and peripheral equipment.

- Identify and replace worn or damaged parts.

- Collaborate with maintenance personnel for major repairs.

Interview Tips

To ace an interview for a Molding Technician position, it is important to showcase your technical skills, problem-solving abilities, and attention to detail. Here are some tips to help you prepare:

1. Research the Company and Industry

Demonstrate your interest in the company and its products by researching their website, industry news, and recent developments. This shows that you have done your homework and are enthusiastic about the opportunity.

- Example: “I have been following your company’s progress in the automotive industry and am impressed with the innovative molding solutions you have developed.”

2. Highlight Relevant Experience and Skills

Emphasize your experience in mold setup and operation, material handling, and quality control. Quantify your achievements whenever possible to demonstrate your impact.

- Example: “In my previous role, I was responsible for setting up and operating a variety of molding machines, resulting in a 15% increase in production efficiency.”

3. Demonstrate Problem-Solving Abilities

Molding Technicians often encounter unexpected challenges. Provide examples of how you have successfully resolved technical issues or improved production processes.

- Example: “I once identified a recurring problem with mold wear. By analyzing the production data and working with the maintenance team, we developed a preventative maintenance schedule that reduced downtime by 20%.”

4. Emphasize Attention to Detail

Molding Technicians must be meticulous in their work. Highlight your ability to follow instructions precisely, inspect products thoroughly, and maintain a clean and organized work environment.

- Example: “I have a strong eye for detail and am committed to ensuring that all products meet the highest quality standards.”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Molding Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Molding Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.