Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Molten Iron Pourer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

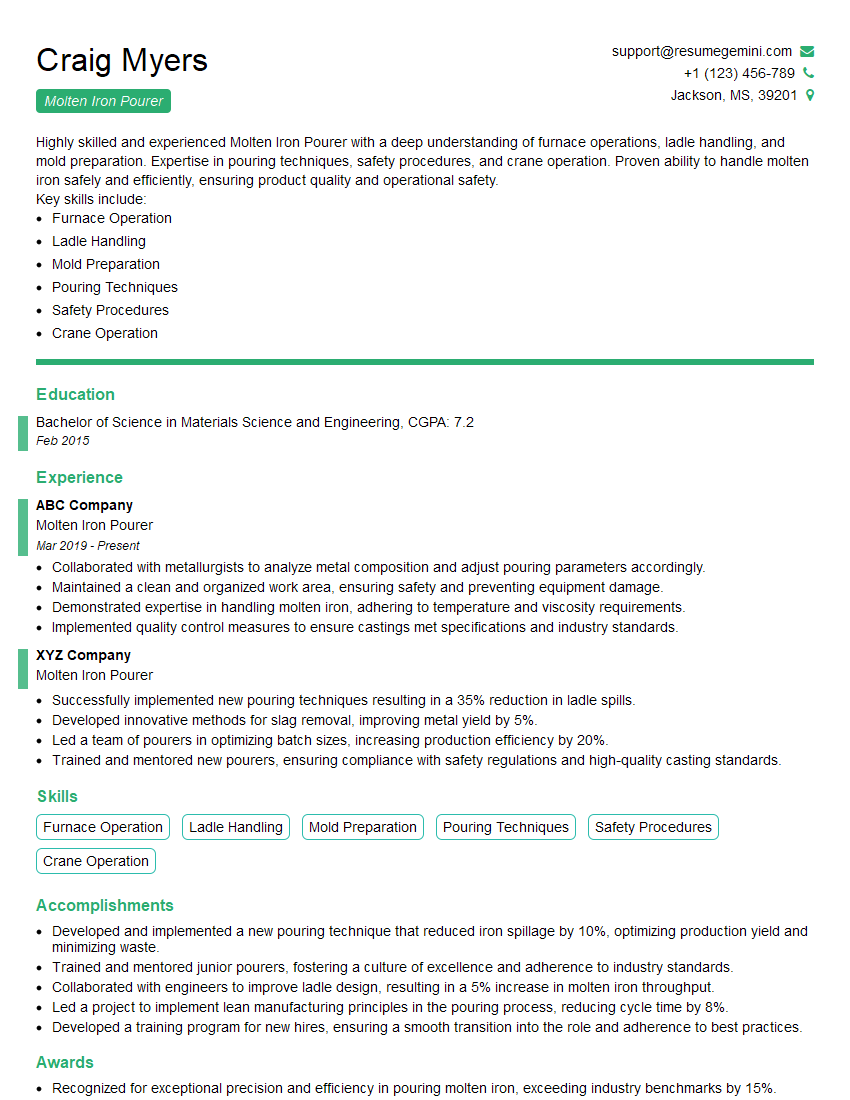

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Molten Iron Pourer

1. What are the key safety precautions that you follow while pouring molten iron?

answer:

- Wear appropriate personal protective equipment (PPE), including a fire-resistant suit, gloves, and face shield.

- Ensure that the pouring area is well-ventilated and free of any combustible materials.

- Check the integrity of the ladle, crucibles, and other equipment before use.

- Maintain a safe distance from the molten iron during pouring.

- Be aware of the potential for splashes and spills.

2. Describe the process of preparing a mold for pouring molten iron.

Steps involved:

- Clean and inspect the mold to ensure it is free of any defects.

- Apply a mold release agent to prevent the molten iron from sticking.

- Assemble the mold and secure it properly.

- Preheat the mold to the desired temperature.

Quality checks:

- Inspect the mold for any cracks or leaks.

- Check the temperature of the mold using a pyrometer.

- Ensure that all mold sections are properly aligned and secured.

3. What are the different types of pouring techniques used?

- Top pouring: Molten iron is poured directly from the ladle into the mold from above.

- Bottom pouring: Molten iron is poured from a ladle into a tundish or runner system that feeds the mold from below.

- Vacuum pouring: Molten iron is poured into a sealed mold chamber under vacuum conditions.

4. What factors affect the quality of the poured iron casting?

- Temperature of the molten iron: The temperature of the molten iron must be within a specific range to ensure proper fluidity and solidification.

- Pouring rate: The rate at which the molten iron is poured can affect the formation of defects such as porosity and shrinkage.

- Mold design: The design of the mold can influence the flow of molten iron and the resulting casting quality.

- Cooling rate: The cooling rate of the molten iron after pouring affects the grain structure and mechanical properties of the casting.

5. How do you handle and troubleshoot common pouring defects?

- Cold shuts: Caused by insufficient molten iron filling the mold. Solutions include increasing the pouring temperature or rate.

- Misruns: Occur when molten iron fails to fill the entire mold. Solutions include modifying the mold design or adjusting the pouring technique.

- Porosity: Caused by the presence of gas bubbles in the molten iron. Solutions involve degassing the molten iron or modifying the pouring process.

- Shrinkage: Arises from the contraction of molten iron as it solidifies. Solutions include using risers or chills to compensate for shrinkage.

6. What are the maintenance and calibration procedures for the equipment used in molten iron pouring?

- Ladles: Regularly inspect for cracks, wear, and refractory damage. Repair or replace as needed.

- Crucibles: Check for cracks, erosion, and contamination. Clean and repair or replace as necessary.

- Pouring nozzles: Inspect for blockages, wear, and damage. Clean and replace as required.

- Temperature sensors: Calibrate regularly using certified standards.

- Safety equipment: Ensure that all PPE and safety devices are in good working order.

7. How do you work effectively as part of a team in a foundry environment?

- Communicate clearly and maintain open communication with team members.

- Assist other team members as needed and contribute to a positive work environment.

- Follow safety protocols and contribute to a safe work environment.

- Seek guidance and support from supervisors when required.

8. What are the potential hazards associated with molten iron pouring?

- Burns: Molten iron can cause severe burns on contact with skin.

- Eye injuries: Sparks and splashes can cause eye injuries.

- Respiratory hazards: Fumes and gases released during pouring can be harmful to inhale.

- Explosions: Contact between molten iron and water can cause explosions.

- Slips and falls: Wet or oily floors can increase the risk of slips and falls.

9. How do you assess the quality of the molten iron before pouring?

- Visual inspection: Observe the molten iron for any visible impurities or defects.

- Temperature measurement: Use a pyrometer to measure the temperature of the molten iron and ensure it is within the desired range.

- Chemical analysis: Analyze the molten iron using spectroscopy or other methods to determine its chemical composition.

- Mechanical testing: Conduct tests such as tensile or hardness tests on samples to evaluate the mechanical properties of the molten iron.

10. Describe the post-pouring process for molten iron castings.

- Cooling: Allow the castings to cool slowly and evenly to prevent cracking.

- Shakeout: Remove the castings from the mold.

- Cleaning: Remove any mold residues, gating systems, or excess material from the castings.

- Heat treatment: Perform heat treatment processes such as annealing or tempering to enhance the mechanical properties and reduce internal stresses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Molten Iron Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Molten Iron Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Molten Iron Pourer, you will work alongside a team of skilled professionals in a high-pressure environment. Your primary responsibility will be safely pouring molten iron into molds to produce various iron products. Your role is crucial in ensuring the smooth functioning of the foundry and maintaining high-quality standards.

1. Molten Iron Handling

Your day-to-day responsibilities will include:

- Operating cranes or other equipment to transport molten iron from the furnaces to the pouring stations.

- Using ladles to carefully pour molten iron into molds, ensuring accuracy and precision.

- Monitoring temperature and fluidity of the molten iron to ensure optimal casting conditions.

2. Mold Preparation and Maintenance

You will be responsible for:

- Inspecting molds for any defects or damage before pouring molten iron.

- Preparing and maintaining mold coatings and release agents to facilitate smooth casting.

- Ensuring that the molds are correctly aligned and secured to prevent spilling or accidents.

3. Safety and Quality Assurance

Safety is paramount in this role. You will be required to:

- Adhere strictly to all safety protocols and procedures to minimize risks.

- Maintain a clean and organized work area to prevent accidents.

- Report any potential hazards or malfunctions promptly to ensure a safe working environment.

4. Communication and Teamwork

Collaboration is key in this role. You will be expected to:

- Communicate effectively with other team members, supervisors, and quality control personnel.

- Coordinate actions to ensure smooth pouring operations and timely delivery of products.

- Participate in training and development programs to enhance your skills and knowledge.

Interview Tips

Preparing thoroughly for your interview is crucial for success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to learn about the company’s history, products, and values. Research the specific Molten Iron Pourer role to understand the responsibilities and expectations.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses that highlight your skills and experience. Practice answering questions aloud to build confidence.

3. Emphasize Safety

Safety is of utmost importance in this role. Showcase your commitment to following safety protocols and maintaining a safe work environment.

4. Demonstrate Teamwork Skills

Provide examples of how you have worked effectively in a team environment and contributed to successful outcomes.

5. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows your interest and engagement. Prepare a few questions to ask the interviewer about the company, the role, or the industry.

6. Dress Professionally

First impressions matter. Dress professionally and arrive on time for your interview.

7. Be Enthusiastic and Confident

Show your passion for the role and convey your confidence in your abilities. Maintain a positive attitude throughout the interview.

8. Follow Up

After the interview, send a thank-you note to the interviewer expressing your appreciation for their time and reiterating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Molten Iron Pourer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!