Are you gearing up for a career in Monomer Recovery Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Monomer Recovery Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

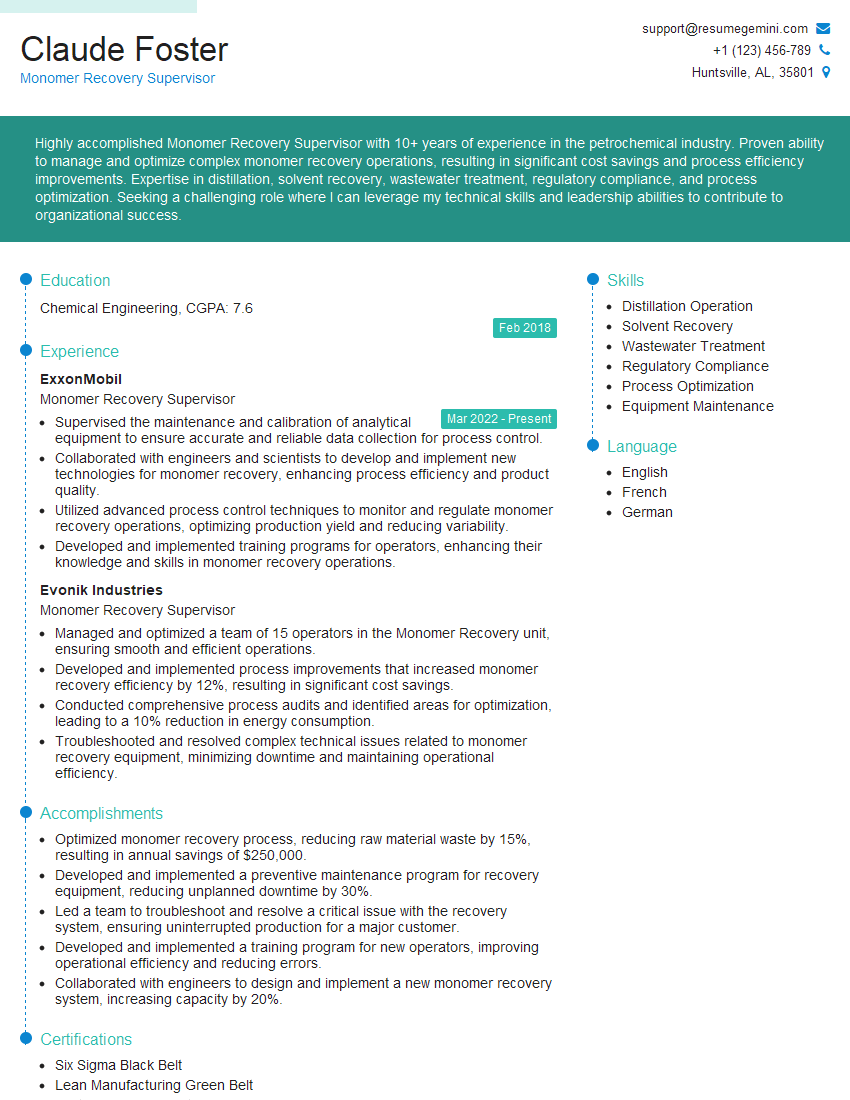

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Monomer Recovery Supervisor

1. Describe the key performance indicators (KPIs) you use to measure the effectiveness of a monomer recovery unit?

The KPIs that I use to measure the effectiveness of a monomer recovery unit include:

- Recovery efficiency: This measures the percentage of monomer that is recovered from the process gas.

- Product purity: This measures the purity of the recovered monomer, typically expressed as a percentage.

- Energy consumption: This measures the amount of energy required to operate the recovery unit, typically expressed in kWh/kg of monomer recovered.

- Maintenance costs: This measures the cost of maintaining the recovery unit, including labor, materials, and repairs.

- Downtime: This measures the amount of time that the recovery unit is not operating, typically expressed as a percentage of total operating time.

2. How do you ensure that the recovered monomer meets the required purity specifications?

Quality Control Procedures

- Establish and implement rigorous quality control procedures throughout the recovery process.

- Regularly monitor and test the purity of the recovered monomer using analytical techniques such as gas chromatography or mass spectrometry.

Process Optimization

- Optimize the recovery process parameters, such as temperature, pressure, and flow rates, to maximize purity.

- Employ advanced separation techniques, such as distillation or membrane separation, to remove impurities.

3. Explain the principles of distillation as applied to monomer recovery.

- Distillation is a separation process that utilizes the differences in volatility between components in a mixture.

- In monomer recovery, distillation is used to separate the monomer from other components in the process gas.

- The process involves heating the mixture to a temperature where the monomer vaporizes, and then condensing the vapor to collect the purified monomer.

4. Describe the different types of distillation columns used in monomer recovery and their advantages and disadvantages.

Different types of distillation columns used in monomer recovery include:

Packed Columns

- Advantages: High separation efficiency, low pressure drop.

- Disadvantages: High capital cost, prone to fouling.

Tray Columns

- Advantages: Simple design, low capital cost.

- Disadvantages: Lower separation efficiency, higher pressure drop.

Membrane Columns

- Advantages: Highly efficient, compact, low energy consumption.

- Disadvantages: Expensive, limited to certain applications.

5. Explain the importance of corrosion control in monomer recovery systems and discuss the methods used to mitigate corrosion.

Corrosion is a major concern in monomer recovery systems due to the presence of highly corrosive chemicals.

Methods to Mitigate Corrosion

- Material Selection: Using corrosion-resistant materials such as stainless steel or titanium.

- Protective Coatings: Applying protective coatings or linings to metal surfaces.

- Corrosion Inhibitors: Adding corrosion inhibitors to the process streams.

- pH Control: Maintaining the pH of the process streams within acceptable limits.

- Regular Inspection and Maintenance: Regularly inspecting and maintaining equipment to identify and address potential corrosion issues.

6. How do you handle and store recovered monomer to maintain its quality and prevent contamination?

- Store the monomer in appropriate containers that are compatible with the material.

- Maintain proper storage conditions, such as temperature, humidity, and light exposure, to preserve its quality.

- Implement measures to prevent contamination, such as using clean equipment and handling procedures.

- Regularly monitor the quality of the stored monomer to ensure it meets specifications.

7. Describe the safety protocols and emergency procedures that are in place for a monomer recovery unit.

- Establish clear safety protocols for all operations, including handling, storage, and equipment maintenance.

- Provide comprehensive training to all personnel on safety procedures and emergency protocols.

- Implement proper ventilation and containment systems to minimize exposure to hazardous chemicals.

- Have emergency response plans in place and conduct regular drills to ensure preparedness.

- Maintain and regularly inspect safety equipment, such as fire extinguishers and personal protective gear.

8. How do you troubleshoot and resolve common operational issues in a monomer recovery unit?

- Identify the root cause of the issue through systematic troubleshooting procedures.

- Analyze data from sensors and instrumentation to monitor process parameters and identify deviations.

- Implement corrective actions based on the analysis, such as adjusting process conditions or performing maintenance.

- Continuously monitor the recovery unit’s performance and make necessary adjustments to optimize efficiency and prevent future issues.

9. Explain the importance of energy efficiency in monomer recovery and describe measures to improve it.

- Energy efficiency reduces operating costs and environmental impact.

- Optimize process parameters, such as temperature and pressure, to minimize energy consumption.

- Utilize energy-efficient equipment and technologies, such as high-efficiency pumps and heat exchangers.

- Implement heat recovery systems to capture and reuse waste heat.

- Regularly monitor energy consumption and identify areas for improvement.

Measures to Improve Energy Efficiency

10. Describe the role of automation and digital technologies in modern monomer recovery units.

- Automation improves efficiency, reliability, and safety.

- Automated control systems monitor and adjust process parameters in real-time.

- Remote monitoring and diagnostics allow for proactive maintenance and troubleshooting.

- Digital technologies, such as data analytics and machine learning, provide insights and predictive capabilities.

- Data analytics helps identify trends and optimize process performance.

- Machine learning algorithms can predict equipment failures and improve maintenance strategies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Monomer Recovery Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Monomer Recovery Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Monomer Recovery Supervisor is responsible for managing and supervising all aspects of the monomer recovery process, including planning, execution, and control. They ensure the efficient and safe operation of the monomer recovery unit, while meeting production targets and quality standards.

1. Planning and Management

Develop and implement plans for monomer recovery operations, including production schedules, resource allocation, and quality control procedures.

- Coordinate with production, maintenance, and other departments to ensure a smooth and efficient production process.

- Monitor production data and identify areas for improvement, implementing corrective actions as necessary.

2. Process Operations

Supervise and monitor the monomer recovery process, including distillation, extraction, and purification.

- Ensure adherence to safety protocols and quality standards throughout the process.

- Troubleshoot process deviations and implement solutions to maintain optimal performance.

3. Equipment Maintenance

Oversee the maintenance and upkeep of monomer recovery equipment, including pumps, vessels, and instrumentation.

- Schedule and coordinate preventive maintenance activities to minimize downtime.

- Collaborate with maintenance technicians to diagnose and repair equipment failures.

4. Quality Assurance

Monitor the quality of recovered monomer, ensuring it meets specifications and regulatory requirements.

- Conduct regular inspections and testing to maintain product quality.

- Implement quality control procedures to prevent contamination and ensure product safety.

Interview Tips

To ace an interview for a Monomer Recovery Supervisor position, consider the following tips and preparation strategies:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and products. Research the specific role you are applying for to understand the key responsibilities and expectations.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and news articles to stay abreast of current trends and developments in monomer recovery.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers out loud. This will help you articulate your skills and experience effectively.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Focus on highlighting your technical abilities, leadership qualities, and problem-solving skills.

3. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare a few insightful questions related to the role, the team, or the industry.

- Examples: “What are the key challenges facing the monomer recovery industry in the next 5 years?” or “How does the company prioritize safety in its monomer recovery operations?”

4. Showcase Your Safety Awareness

Monomer recovery involves handling hazardous chemicals, so emphasize your knowledge of safety protocols and your commitment to maintaining a safe work environment.

- Provide examples of your experience in implementing safety measures and ensuring compliance with regulatory standards.

- Discuss your understanding of the Material Safety Data Sheets (MSDSs) for the chemicals used in the process.

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Dress professionally, arrive on time, and conduct yourself in a respectful manner.

- Convey your passion for the industry and your eagerness to contribute to the success of the company.

- Remember that the interview is a two-way street, allowing you to assess whether the position and company are a good fit for you.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Monomer Recovery Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Monomer Recovery Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.