Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Monotype Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

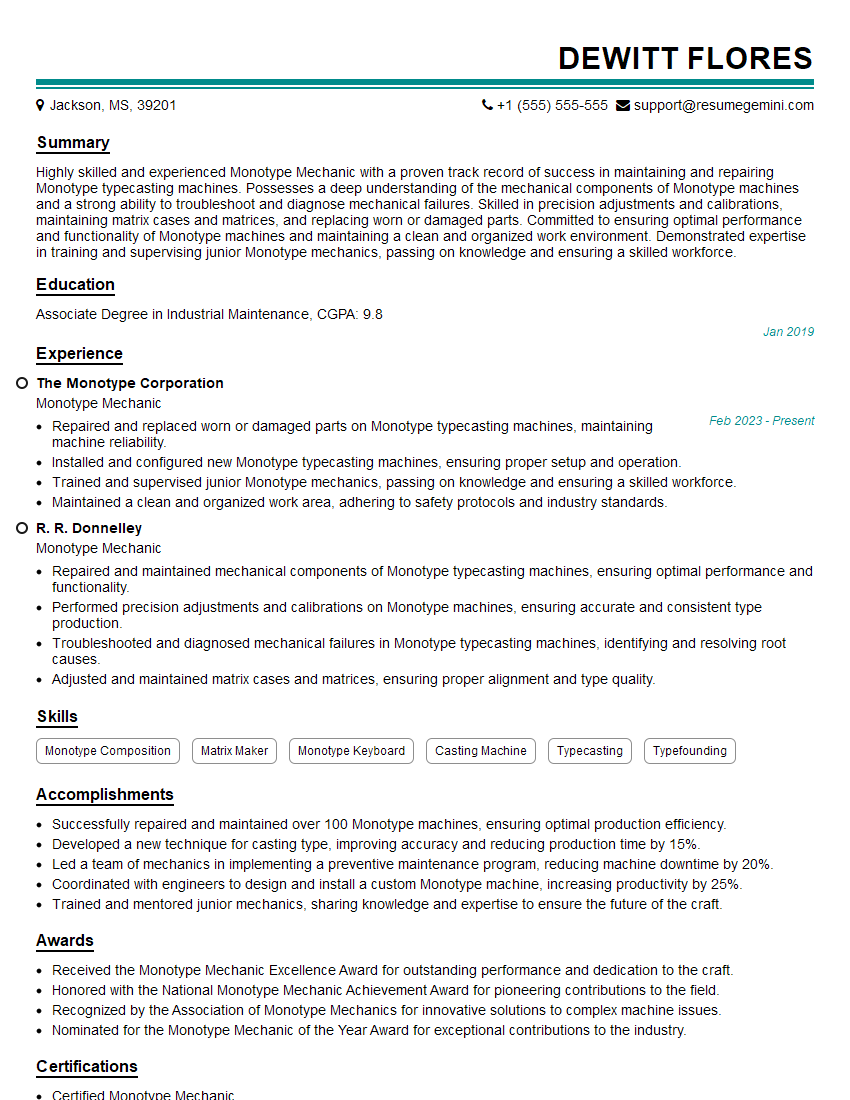

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Monotype Mechanic

1. What are the different types of monotype machines?

Monotype machines can be either a keyboard machine or a caster machine. The keyboard machine is used to create the paper tape that is used to control the caster machine. The caster machine is used to create the metal type that is used to print the text.

2. What are the main components of a monotype machine?

Keyboard Machine

- Keyboard

- Paper tape punch

- Mechanism for creating the paper tape

Caster Machine

- Metal type mold

- Molten metal pot

- Casting mechanism

3. How does a monotype machine work?

- The operator types the text on the keyboard of the keyboard machine.

- The keyboard machine punches the corresponding holes in the paper tape.

- The paper tape is then fed into the caster machine.

- The caster machine reads the holes in the paper tape and creates the metal type.

4. What are the advantages and disadvantages of using a monotype machine?

Advantages

- High quality of print

- Versatile and can be used to print a wide range of materials

- Durable and can last for many years

Disadvantages

- Slow and time-consuming to use

- Requires a skilled operator

- Can be expensive to purchase and maintain

5. What are the safety precautions that should be taken when operating a monotype machine?

- Wear appropriate safety gear, such as safety glasses and gloves.

- Be aware of the moving parts of the machine and keep your hands away from them.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

- Follow all of the manufacturer’s instructions for operating the machine.

6. What are the different types of maintenance that a monotype machine requires?

- Regular cleaning and lubrication

- Periodic adjustments and repairs

- Major overhauls as needed

7. What are the troubleshooting procedures for a monotype machine?

- Check the power supply.

- Check the paper tape for any tears or holes.

- Check the metal type mold for any damage.

- Check the molten metal pot for any leaks.

- Check the casting mechanism for any problems.

8. What are the different types of training that a monotype mechanic needs?

- Formal training from a manufacturer or technical school

- On-the-job training from an experienced monotype mechanic

- Self-study through books, manuals, and online resources

9. What are the different certifications that a monotype mechanic can earn?

- Certified Monotype Mechanic (CMM) from the International Monotype Composition Association (IMCA)

- Monotype Service Technician (MST) from Heidelberg USA

- Monotype Certified Technician (MCT) from Monotype Imaging

10. What are the career opportunities for a monotype mechanic?

- Monotype mechanic

- Printing press operator

- Bindery worker

- Quality control inspector

- Sales representative

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Monotype Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Monotype Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Monotype Mechanics are responsible for maintaining and repairing monotype machines, used in printing processes. They ensure that the machines are in good working condition and perform at optimal efficiency.

1. Maintenance and Inspection

Conduct regular inspections of monotype machines to identify potential issues and prevent breakdowns.

- Inspect mechanical components, such as gears, shafts, and bearings, for wear and damage.

- Check electrical systems, including wiring, switches, and motors, for proper functionality.

2. Repairs and Troubleshooting

Diagnose and repair malfunctions in monotype machines using specialized tools and techniques.

- Identify the cause of breakdowns through observation, testing, and analysis.

- Replace or repair faulty components, such as gears, belts, or electrical circuits.

3. Calibration and Adjustment

Calibrate and adjust monotype machines to ensure accurate and consistent printing results.

- Adjust ink flow, pressure, and alignment settings to optimize print quality.

- Perform preventive maintenance tasks to minimize downtime and extend machine lifespan.

4. Machine Operation and Training

Operate monotype machines to produce high-quality prints and train others on their use.

- Set up and operate monotype machines according to manufacturer’s specifications.

- Provide training and support to users on machine operation and maintenance procedures.

Interview Preparation Tips

Preparing thoroughly for your Monotype Mechanic interview is crucial to showcase your skills and knowledge. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company, its products or services, and the specific industry it operates in. This demonstrates your interest and enthusiasm for the role.

2. Practice Common Interview Questions

Prepare answers to commonly asked interview questions, such as “Tell me about yourself” or “Why are you interested in this position?” Tailor your responses to the specific requirements of the Monotype Mechanic role.

3. Highlight Your Technical Skills

Emphasize your knowledge and experience in monotype machine maintenance and repair. Provide examples of successful troubleshooting and repair scenarios you have encountered.

4. Demonstrate Problem-Solving Abilities

Share examples of how you have effectively solved technical problems in previous roles. Explain your analytical approach and the steps you took to identify and resolve issues.

5. Showcase Your Attention to Detail

Highlight your meticulous nature and attention to detail. Explain how you prioritize accuracy and precision in your work, ensuring the proper functioning of monotype machines.

6. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your engagement and interest in the role. Prepare questions about the company’s operations, the specific responsibilities of the position, or any opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Monotype Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.