Are you gearing up for a career in Mortising Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mortising Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

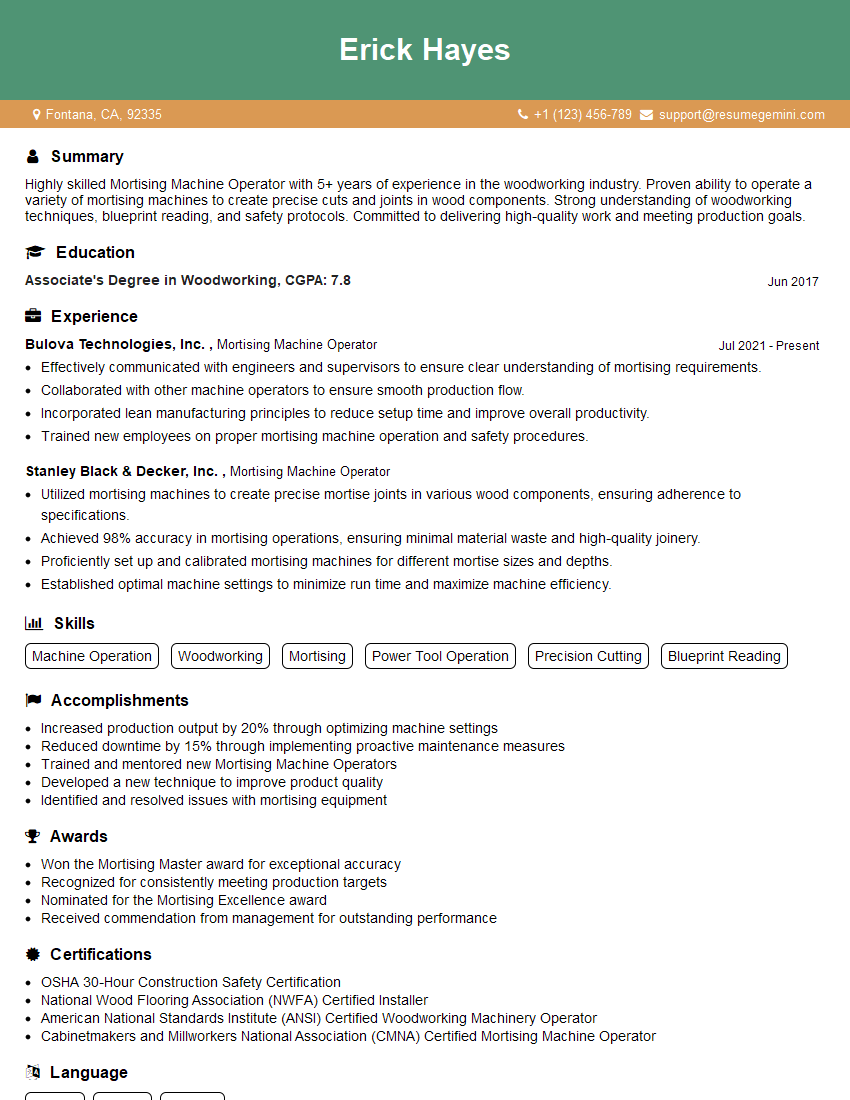

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mortising Machine Operator

1. Describe the different types of mortising machines and their applications.

There are two main types of mortising machines: horizontal and vertical. Horizontal mortising machines are used for mortising holes in the face of a workpiece, while vertical mortising machines are used for mortising holes in the edge of a workpiece. There are also specialized mortising machines, such as chain mortisers and hollow chisel mortisers, which are used for specific applications.

2. What are the key factors to consider when selecting a mortising machine?

Factors to Consider

- The size and type of workpieces that will be mortised.

- The precision and accuracy required for the mortises.

- The production volume and speed required.

- The available budget.

3. What are the different types of mortising bits and when should each type be used?

There are many different types of mortising bits, each with its own specific application. Some of the most common types of mortising bits include:

- Single-lip bits: These bits are used for general-purpose mortising.

- Double-lip bits: These bits are used for mortising where a clean finish is required.

- Hollow chisel bits: These bits are used for mortising large or deep holes.

- Chain bits: These bits are used for mortising curves or irregular shapes.

4. How do you set up and operate a mortising machine?

To set up and operate a mortising machine, follow these steps:

- Select the appropriate mortising bit and insert it into the machine.

- Adjust the table height and fence to the desired position.

- Set the depth of cut and feed rate.

- Secure the workpiece to the table.

- Start the machine and feed the workpiece into the bit.

5. How do you maintain and troubleshoot a mortising machine?

To maintain and troubleshoot a mortising machine, follow these steps:

- Clean the machine regularly and lubricate all moving parts.

- Inspect the mortising bits for damage and replace them if necessary.

- Check the table and fence for alignment and adjust them if necessary.

- If the machine is not operating properly, consult the manufacturer’s manual for troubleshooting tips.

6. What safety precautions should be taken when operating a mortising machine?

When operating a mortising machine, always follow these safety precautions:

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Keep your hands away from the cutting bit.

- Secure the workpiece firmly to the table.

- Never leave the machine running unattended.

- Follow all manufacturer’s instructions for safe operation.

7. What are the common problems that can occur when operating a mortising machine and how can they be resolved?

Some common problems that can occur when operating a mortising machine include:

- The mortise is not the correct size or shape.

- The mortise is not located in the correct position.

- The mortise is not clean or smooth.

- The machine is making excessive noise or vibration.

These problems can be resolved by:

- Checking the mortising bit for damage and replacing it if necessary.

- Adjusting the table height and fence to the correct position.

- Setting the correct depth of cut and feed rate.

- Inspecting the machine for any loose parts or damage and repairing or replacing them as necessary.

8. What are the advantages and disadvantages of using a mortising machine?

Advantages

- Mortising machines can produce precise and accurate mortises.

- Mortising machines can be used to mortise a variety of materials, including wood, metal, and plastic.

- Mortising machines can be used to produce mortises of different sizes and shapes.

Disadvantages

- Mortising machines can be expensive to purchase and maintain.

- Mortising machines can be dangerous to operate if proper safety precautions are not followed.

- Mortising machines can be time-consuming to set up and operate.

9. What are some tips for getting the most out of a mortising machine?

To get the most out of a mortising machine, follow these tips:

- Use sharp mortising bits.

- Set the correct depth of cut and feed rate.

- Secure the workpiece firmly to the table.

- Follow all manufacturer’s instructions for safe operation.

- Practice on scrap wood before mortising your actual workpiece.

10. What are the future trends in mortising machine technology?

Some of the future trends in mortising machine technology include:

- The development of more compact and portable mortising machines.

- The development of mortising machines with more advanced features, such as automatic depth control and bit sharpening.

- The development of mortising machines that can be integrated with other woodworking machines, such as CNC routers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mortising Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mortising Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mortising Machine Operator is responsible for operating and maintaining mortising machines. These machines are used to create mortises, which are holes or recesses in wood, typically for the purpose of joining two pieces of wood together.

1. Set up and operate mortising machine

The operator must be able to set up and operate the mortising machine according to the specifications of the job. This includes setting the speed, depth, and angle of the mortise and ensuring that the machine is properly lubricated and maintained.

- Adjusts and maintains mortising machines to ensure proper operation.

- Inspects and cleans mortising machines to ensure optimal performance.

2. Cut mortises according to specifications

The operator must be able to cut mortises according to the specifications of the job. This includes making sure that the mortises are the correct size, shape, and location. The operator must also be able to make adjustments to the machine as needed to ensure that the mortises are cut accurately.

- Positions and secures wood pieces in mortising machine.

- Operates machine to cut mortises of specified dimensions.

3. Inspect mortises and make adjustments

The operator must be able to inspect mortises and make adjustments as needed. This includes checking the size, shape, and location of the mortises. The operator must also be able to make adjustments to the machine as needed to ensure that the mortises are cut accurately.

- Inspects mortises for quality and accuracy.

- Makes adjustments to machine settings to ensure mortises meet specifications.

4. Maintain work area

The operator must be able to maintain the work area clean and organized. This includes keeping the machine clean and free of debris and ensuring that the work area is well-lit and ventilated.

- Cleans and maintains work area and equipment.

- Follows safety procedures and wears appropriate personal protective equipment (PPE).

Interview Tips

To ace the interview for a Mortising Machine Operator position, you need to be well-prepared. Here are a few tips to help you:

1. Research the company and the position

Take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website to learn more about their business, products, and services.

- Read online reviews of the company to get a sense of what it’s like to work there.

- Talk to your network to see if anyone you know has worked for the company or in a similar role.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Prepare an elevator pitch that highlights your skills and experience and why you’re a good fit for the position.

- Think about specific examples from your past experience that demonstrate your skills and abilities.

- Be prepared to talk about your strengths and weaknesses and how you can use your strengths to overcome your weaknesses.

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, as being late can reflect poorly on you.

- Wear clean, pressed clothes and make sure your shoes are polished.

- Arrive at the interview location at least 10 minutes early.

- Be polite and respectful to everyone you meet, including the receptionist and the interviewer.

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Let the interviewer know why you’re interested in the position and why you think you’re the best person for the job.

- Smile and make eye contact with the interviewer.

- Be confident in your abilities and your worth as a candidate.

- Thank the interviewer for their time and consideration.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mortising Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.