Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Movable Bulkhead Installer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

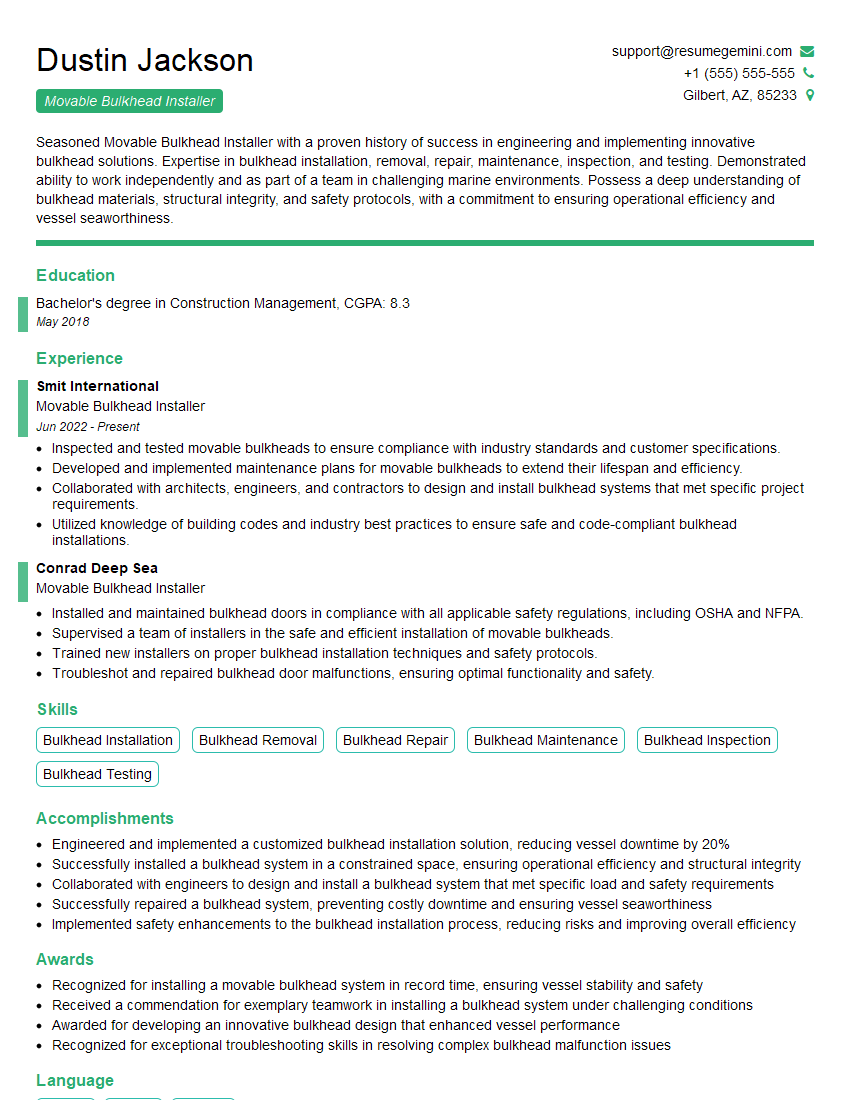

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Movable Bulkhead Installer

1. Explain the process of installing a movable bulkhead on a ship?

The process of installing a movable bulkhead on a ship involves several key steps:

- Preparation: Gather necessary tools, materials, and safety gear. Inspect the area where the bulkhead will be installed to ensure it is clear and safe.

- Assembly: Assemble the bulkhead components according to the manufacturer’s instructions.

- Positioning: Position the bulkhead in the designated location on the ship. Use lifting equipment if necessary.

- Alignment: Align the bulkhead with the ship’s structure using precision instruments and measurements.

- Securing: Secure the bulkhead to the ship’s structure using bolts, gaskets, and other fastening materials.

- Testing: Conduct tests to ensure the bulkhead is watertight and operates smoothly.

2. What are the different types of movable bulkheads used on ships?

Types of Movable Bulkheads:

- Rolling Bulkheads: Horizontally retractable bulkheads that roll into a storage space when not in use.

- Sliding Bulkheads: Vertically movable bulkheads that slide up and down to adjust compartment sizes.

- Folding Bulkheads: Hinged bulkheads that can be folded away when not needed.

- Watertight Doors: Watertight bulkheads with a single or double door for personnel passage.

- Gas-Tight Bulkheads: Bulkheads designed to prevent the passage of gas or smoke.

Selection Factors:

- Ship type

- Compartment layout

- Watertight and gas-tight requirements

- Space availability

3. Describe the maintenance procedures for movable bulkheads?

Maintenance procedures for movable bulkheads include:

- Regular Inspection: Visually inspect bulkheads for any damage, wear, or leaks.

- Lubrication: Grease moving parts, such as hinges and bearings, to ensure smooth operation.

- Testing: Conduct periodic watertight tests to verify the integrity of the bulkhead.

- Repairs: Repair any damage or leaks promptly to maintain watertightness.

- Documentation: Keep detailed records of all maintenance activities.

4. How do you ensure the watertight integrity of a movable bulkhead?

Ensuring watertight integrity involves several key measures:

- Proper Installation: Install the bulkhead according to manufacturer’s specifications.

- Gaskets and Seals: Use high-quality gaskets and seals to prevent water ingress.

- Tightening and Bolting: Ensure all bolts and fasteners are tightened to the specified torque.

- Inspection and Testing: Regularly inspect bulkheads for any leaks or damage. Conduct watertight tests to verify integrity.

- Maintenance: Perform regular maintenance to keep bulkheads in optimal condition.

5. What are the safety precautions to consider when working with movable bulkheads?

Safety precautions when working with movable bulkheads include:

- Personal Protective Equipment: Wear appropriate safety gear, including safety glasses, gloves, and hard hat.

- Lifting Equipment: Use proper lifting equipment when handling heavy bulkhead components.

- Electrical Hazards: Ensure electrical connections are made by qualified personnel.

- Confined Spaces: Follow safety protocols when working in confined spaces, such as inside bulkheads.

- Training: Receive proper training on bulkhead operation and maintenance procedures.

6. How do you interpret technical drawings and specifications for movable bulkheads?

Interpreting technical drawings and specifications for movable bulkheads involves:

- Understanding Symbols: Familiarize yourself with industry-standard symbols and notations used in drawings.

- Dimensioning: Pay attention to dimensions and tolerances specified in the drawings.

- Cross-Referencing: Refer to related drawings and specifications for additional information.

- Material Specifications: Understand the material requirements and specifications for bulkhead components.

- Installation Instructions: Follow the step-by-step installation instructions provided in the drawings.

7. Describe the role of movable bulkheads in ship stability and damage control?

Movable bulkheads play a crucial role in ship stability and damage control:

- Compartmentation: Bulkheads divide the ship into smaller compartments, limiting the extent of flooding in case of damage.

- Stability: Movable bulkheads can be adjusted to optimize the ship’s stability by altering the distribution of weights.

- Damage Control: Bulkheads can be used to isolate damaged compartments, preventing further ingress of water and ensuring crew safety.

- Temporary Repairs: Movable bulkheads can be used to temporarily seal off damaged areas, allowing for emergency repairs.

8. How do you maintain communication and coordination with other team members during bulkhead installation or maintenance?

Effective communication and coordination are essential:

- Clear Instructions: Provide clear and concise instructions to team members.

- Regular Updates: Keep team members updated on progress and any issues encountered.

- Team Briefings: Hold briefings to discuss the task, safety procedures, and responsibilities.

- Visual Cues: Use visual cues, such as hand signals, to communicate during noisy or hazardous environments.

- Emergency Protocols: Establish clear emergency protocols and ensure all team members are aware of them.

9. What is the importance of following safety regulations and standards when working with movable bulkheads?

Following safety regulations and standards is crucial for several reasons:

- Worker Safety: Ensures the safety of personnel involved in bulkhead installation and maintenance.

- Prevent Damage: Adherence to standards helps prevent damage to equipment and the ship itself.

- Regulatory Compliance: Meeting regulations ensures compliance with industry standards and legal requirements.

- Insurance Coverage: Following safety protocols can impact insurance coverage in case of accidents or incidents.

- Quality Assurance: Standards provide guidelines for proper installation and maintenance, ensuring quality and reliability.

10. How do you stay updated on the latest technologies and best practices in movable bulkhead installation and maintenance?

To stay updated on the latest technologies and best practices, I employ the following methods:

- Industry Publications: Subscribe to industry magazines and journals to access technical articles and updates.

- Conferences and Webinars: Attend industry conferences and webinars to learn from experts and network with peers.

- Manufacturer Training: Seek training and certification from bulkhead manufacturers to enhance my knowledge and skills.

- Online Resources: Explore reputable websites and online databases for technical information and research.

- Collaboration: Share knowledge and exchange ideas with colleagues and industry professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Movable Bulkhead Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Movable Bulkhead Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Movable Bulkhead Installers play a crucial role in ensuring the safe and efficient operation of specialized vessels, such as Ro-Ro ships, by installing and maintaining movable bulkheads that divide the ship’s cargo hold into separate compartments.

1. Installation and Maintenance

Install, repair, and maintain movable bulkheads according to specifications and safety regulations.

- Assemble and install bulkhead components, including panels, tracks, and locking mechanisms.

- Inspect, adjust, and maintain bulkheads to ensure proper operation and adherence to safety standards.

2. Operational Procedures

Operate movable bulkheads efficiently and safely during loading, unloading, and transit.

- Maneuver bulkheads to divide and reconfigure the cargo hold as needed.

- Monitor bulkhead movement and ensure smooth and secure operation during cargo operations.

3. Safety and Compliance

Adhere to safety protocols and regulations related to bulkhead systems.

- Conduct safety inspections and maintain records to ensure compliance with safety standards.

- Participate in training and drills to enhance safety awareness and response capabilities.

4. Teamwork and Communication

Collaborate effectively with other crew members and supervisors.

- Communicate clearly and effectively with colleagues and superiors regarding bulkhead operations and maintenance.

- Work as part of a team to ensure the smooth and efficient functioning of the vessel’s cargo operations.

Interview Tips

To prepare effectively for an interview as a Movable Bulkhead Installer, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s operations, target industry, and specific requirements for the installer position.

- Review the job description thoroughly to understand the key responsibilities and expectations.

- Research the company’s website and industry news to gain insights into their culture and operations.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in bulkhead installation and maintenance, as well as your understanding of safety protocols.

- Provide specific examples of your experience in assembling, adjusting, and troubleshooting bulkhead systems.

- Showcase your knowledge of safety regulations and your commitment to adhering to them.

3. Demonstrate Teamwork and Communication Skills

Interviewers are likely to assess your ability to work collaboratively and communicate effectively.

- Share examples of how you have successfully collaborated with colleagues to achieve project goals.

- Describe your approach to communication, highlighting your ability to convey technical information clearly and concisely.

4. Prepare for Technical Questions

Anticipate questions related to movable bulkhead systems, including their operation, maintenance, and safety features.

- Study the principles of bulkhead design and engineering.

- Review common troubleshooting procedures and safety protocols associated with bulkhead systems.

5. Be Enthusiastic and Professional

Convey your passion for the role and your commitment to contributing to the team’s success.

- Express your interest in the company and the industry.

- Maintain a professional demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Movable Bulkhead Installer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!