Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mucking Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mucking Machine Operator so you can tailor your answers to impress potential employers.

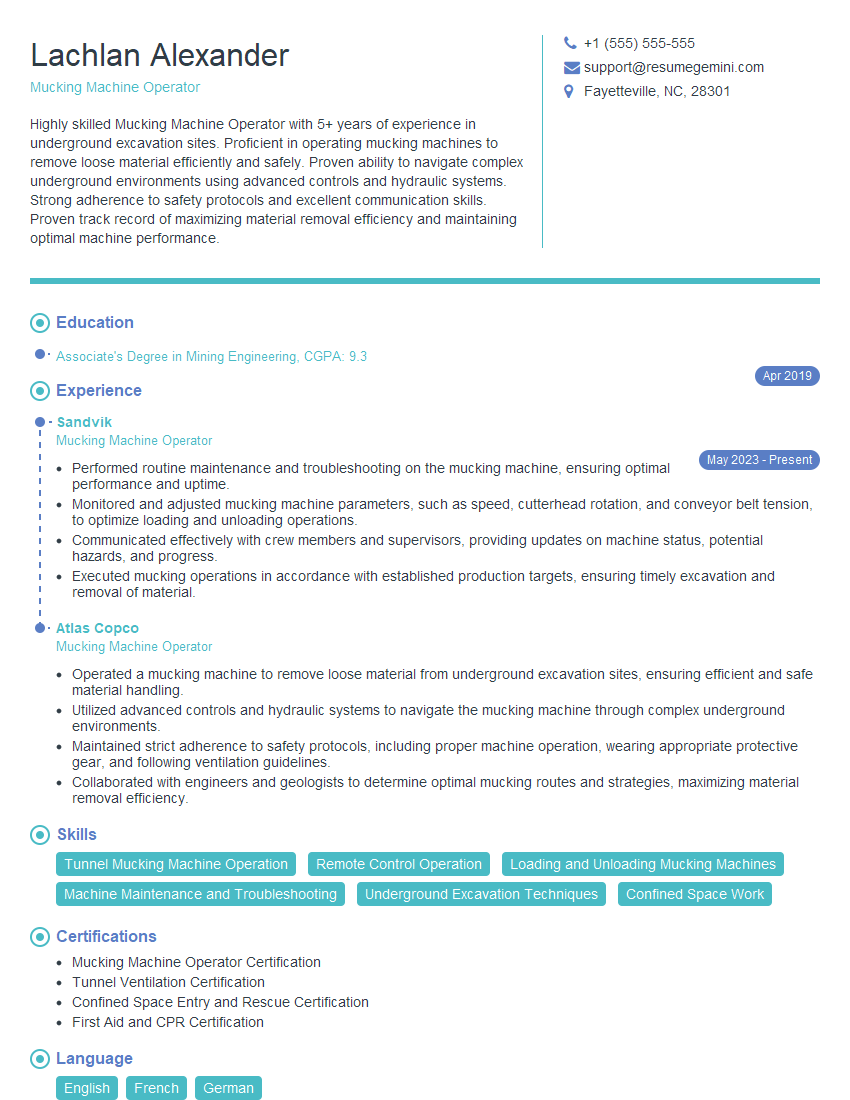

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mucking Machine Operator

1. Describe the key components of a mucking machine.

- Haulage system: Consists of a conveyor belt and drive mechanism to transport the excavated material.

- Cutting head: Rotates and breaks down the material into smaller pieces.

- Boom and arm: Allows for precise maneuvering and positioning of the cutting head.

- Hydraulic system: Provides power and control to the various components.

- Operator cabin: Houses the controls and provides a safe and ergonomic environment for the operator.

2. How do you ensure the safe and efficient operation of a mucking machine?

Conduct Pre-Operational Checks

- Inspect the machine for any damage or defects.

- Check fluid levels and lubricate moving parts.

- Verify the proper functioning of all safety devices.

During Operation

- Maintain a safe distance from unsupported areas and hazardous materials.

- Monitor the machine’s performance and adjust settings as necessary.

- Communicate effectively with other crew members.

3. Explain the different types of ground conditions that mucking machines can handle and how you adjust the machine accordingly.

- Loose and Unconsolidated: Use a low cutting head speed and high conveyor speed.

- Semi-Hard: Increase the cutting head speed and reduce the conveyor speed.

- Hard and Compacted: Use a high torque cutting head and adjust the boom and arm angles for optimal leverage.

- Wet or Slurry: Install a dewatering system and utilize a cutting head designed for wet conditions.

4. How do you troubleshoot common problems that arise while operating a mucking machine?

- Conveyor belt blockage: Inspect the belt for foreign objects or damage, and clear it accordingly.

- Hydraulic system failure: Check fluid levels, inspect for leaks, and bleed the system if necessary.

- Cutting head jammed: Stop the machine, remove the blockage, and restart with caution.

- Overheating: Allow the machine to cool down, check fluid levels, and clean any clogged filters.

5. How do you calculate the mucking rate and estimate the time required to complete a mucking job?

- Determine the machine’s capacity: Measure the volume of material the machine can transport per cycle.

- Estimate the volume of material: Calculate the area and depth of the excavation to determine the total volume.

- Divide the volume by the capacity: Calculate the number of cycles required to remove the material.

- Multiply by the cycle time: Determine the estimated time based on the machine’s average cycle time.

6. What is the importance of maintaining proper ventilation and dust control when operating a mucking machine?

- Prevents respiratory problems: Inhalation of dust and fumes can lead to lung damage and other health issues.

- Reduces fire hazard: Dust and debris can accumulate and create a fire hazard if not properly controlled.

- Improves visibility: Dust and fumes can obstruct visibility, making it difficult to operate the machine safely.

- Complies with safety regulations: Maintaining proper ventilation and dust control is often a legal requirement in many jurisdictions.

7. Explain the importance of maintaining a clean and well-maintained mucking machine.

- Ensures efficient operation: A clean machine experiences less friction and operates more smoothly.

- Extends equipment life: Regular maintenance prevents premature wear and tear, prolonging the lifespan of the machine.

- Reduces downtime: Timely maintenance identifies potential issues early on, preventing costly breakdowns.

- Promotes safety: A well-maintained machine is less likely to malfunction or cause accidents.

8. Describe the safety measures you implement when working in confined spaces such as tunnels or underground mines.

- Ventilation: Ensure adequate ventilation to prevent oxygen depletion and toxic gas accumulation.

- Gas monitoring: Utilize gas detectors to monitor for hazardous gases and evacuate if necessary.

- Barricades: Use barricades or warning tape to restrict access to hazardous areas.

- Communication: Maintain clear communication with the crew and surface personnel.

- Emergency preparedness: Have an emergency plan in place and be equipped with appropriate safety gear.

9. What are the challenges of operating a mucking machine in wet or muddy conditions?

- Reduced traction: Wet or muddy ground can reduce the machine’s ability to move effectively.

- Slippage: The conveyor belt can become slippery, making material transport difficult.

- Mud buildup: Mud can accumulate on the machine, hindering its performance.

- Corrosion: Wet conditions can accelerate corrosion of the machine’s components.

10. Explain how you coordinate with other crew members to ensure smooth and efficient operation of the mucking machine.

- Establish clear communication channels: Set up radio or hand signals to communicate effectively.

- Assign roles and responsibilities: Ensure each crew member understands their tasks and responsibilities.

- Coordinate timing: Plan the sequence of operations to avoid delays and bottlenecks.

- Provide feedback and support: Communicate any issues or observations to the crew for prompt resolution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mucking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mucking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mucking Machine Operators are pivotal in the underground mining industry, responsible for the operation of mucking machines. These specialized machines are employed to collect and load excavated material from mining faces and transport it to designated areas within the mine.

1. Efficient Mucking Machine Operation

Skilfully operate mucking machines to gather and load excavated materials, such as rocks, soil, and ore.

- Maintain optimal machine performance and ensure smooth operation.

- Monitor machine functions, including hydraulics, controls, and safety systems, to identify and resolve any issues promptly.

2. Safe and Precise Material Handling

Accurately position and maneuver the mucking machine to optimize material collection and minimize spills.

- Ensure safe and efficient transportation of materials to designated loading areas or conveyors.

- Adhere to established safety protocols and regulations to prevent accidents and maintain a safe working environment.

3. Mine Environment Maintenance

Contribute to maintaining a clean and organized mine environment by promptly removing accumulated materials.

- Clear work areas of debris and potential hazards to enhance safety and productivity.

- Assist in maintaining proper ventilation and dust control measures to ensure a healthy work environment.

4. Teamwork and Communication

Effectively collaborate with other mining personnel, including machine operators, supervisors, and engineers.

- Communicate clearly and concisely to coordinate activities and ensure smooth operations.

- Actively participate in safety meetings and training sessions to stay informed and enhance teamwork.

Interview Tips

Preparing for an interview can be daunting, but with the right tips and strategies, you can increase your chances of success. Here are some valuable interview preparation hacks to help you ace your Mucking Machine Operator interview:

1. Research the Company and Role

Take the time to thoroughly research the mining company and the specific role you are applying for. Familiarize yourself with their operations, industry reputation, and company culture. This shows the interviewer that you are genuinely interested in the position and have taken the initiative to learn more.

- Visit the company’s website and social media pages to gather information about their values, recent projects, and news.

- Read industry publications and articles to stay updated on the latest trends and technologies in mining.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice answering questions related to your mucking machine operation abilities, safety procedures, and teamwork experience.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Highlight Your Safety Commitment

Safety is paramount in the mining industry. Emphasize your commitment to following safety protocols and maintaining a safe work environment. Share examples of how you have proactively identified and mitigated potential hazards in previous roles.

- Mention any relevant safety certifications or training you have completed.

- Discuss your understanding of the company’s safety policies and procedures.

4. Showcase Your Technical Skills

Technical proficiency is crucial for Mucking Machine Operators. Clearly articulate your expertise in operating and maintaining mucking machines. Describe your experience in troubleshooting common issues and ensuring optimal machine performance.

- Highlight any specific types of mucking machines you have operated successfully.

- If possible, provide examples of how you have used your technical skills to solve problems or improve efficiency.

5. Prepare Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare questions that are specific to the company or the position. This shows that you have listened attentively and are eager to learn more.

- Inquire about the company’s future projects or growth plans.

- Ask about opportunities for professional development or training.

Next Step:

Now that you’re armed with the knowledge of Mucking Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mucking Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini