Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mud Mill Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mud Mill Tender so you can tailor your answers to impress potential employers.

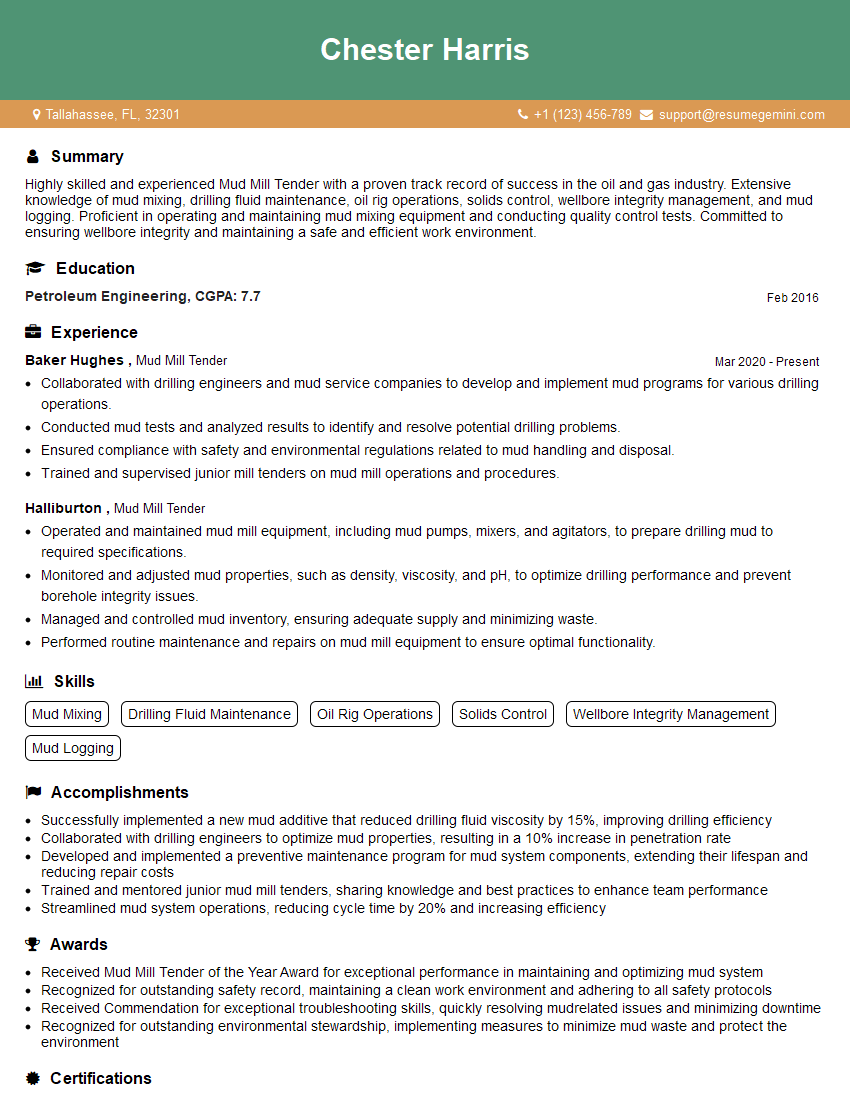

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mud Mill Tender

1. Describe the primary responsibilities of a Mud Mill Tender?

Operate mud mill to prepare the drilling fluid. Monitor and control drilling fluid properties, such as density, viscosity, and pH level. Add chemicals and polymers to adjust drilling fluid properties. Keep records of drilling fluid usage and maintenance. Ensure proper lubrication and maintenance of mud mill equipment.

2. Explain the importance of maintaining optimal drilling fluid properties?

Drilling Efficiency

- Reduced friction and torque on drill string, resulting in faster drilling rates.

- Improved hole cleaning, removing cuttings and preventing formation damage.

Wellbore Stability

- Prevent wellbore collapse or formation fracturing by maintaining appropriate hydrostatic pressure.

- Stabilize formation fluids and prevent fluid loss.

3. What are the common types of drilling fluids used in mud mills?

Water-based muds Oil-based muds Synthetic-based muds Pneumatic drilling fluids Aerated drilling fluids

4. Describe the process of preparing drilling fluid in a mud mill?

Pump base fluid (water, oil, or synthetic) into mud pit. Add and mix desired chemicals and polymers according to recipe. Circulate drilling fluid through mud mill to agitate and blend components. Monitor and adjust drilling fluid properties as needed.

5. How do you handle emergencies related to mud mill operations?

In case of a mud spill or leak, immediately contain the spill and notify supervisor. Wear appropriate protective gear to prevent contact with hazardous fluids. Identify the source of the leak and take steps to stop it. Clean up the affected area and dispose of contaminated materials safely.

6. Explain the role of drilling fluid in preventing wellbore kick?

Creates hydrostatic pressure to balance formation pressure and prevent formation fluids from entering the wellbore. Lubricates and cools the drill bit, reducing friction and preventing sticking.

7. How do you ensure the proper disposal of drilling fluid waste?

Follow company and regulatory guidelines for waste disposal. Transport and dispose of drilling fluid waste in licensed facilities. Minimize waste generation and promote sustainable practices.

8. Describe the safety precautions that must be taken when working with drilling fluids?

Wear appropriate personal protective equipment (PPE), including gloves, goggles, and protective suits. Handle chemicals carefully and follow MSDS guidelines. Maintain a clean and organized work environment. Be aware of potential hazards and take necessary precautions.

9. How do you stay updated on the latest advancements in mud mill operations and drilling fluid technology?

Attend industry conferences and workshops. Read technical journals and publications. Consult with experts and vendors. Participate in training and certification programs.

10. Describe a situation where you faced a technical challenge related to mud mill operations and how you resolved it?

Explain the problem encountered, the steps taken to troubleshoot, and the solution implemented. Highlight your problem-solving skills and technical knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mud Mill Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mud Mill Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Mud Mill Tender, your responsibilities will encompass a range of crucial tasks that contribute to the smooth and efficient operation of a mud mill.

1. Equipment Operation and Maintenance

Your primary task is to operate and maintain the mud mill equipment, ensuring its functionality and adherence to safety regulations.

- Operate mud mills to grind and mix drilling fluids, ensuring proper consistency and viscosity.

- Monitor equipment gauges and sensors to ensure optimal performance and troubleshoot any malfunctions promptly.

- Perform regular equipment maintenance, including lubrication, cleaning, and repairs, to extend equipment life.

2. Drilling Fluid Management

You are responsible for managing the drilling fluids used in the drilling process, ensuring they meet the required specifications.

- Maintain and monitor drilling fluid properties, such as density, viscosity, and pH, to optimize drilling performance.

- Control and adjust mud additives to achieve desired fluid properties, ensuring wellbore stability and efficient drilling.

- Monitor mud tanks and fluid circulation systems to maintain proper fluid levels and prevent contamination.

3. Safety and Compliance

Safety is paramount in your role. You are responsible for adhering to safety protocols and ensuring the well-being of yourself and others.

- Follow established safety guidelines and procedures, including wearing appropriate protective gear and operating equipment safely.

- Identify and assess potential hazards in the work area and take appropriate measures to mitigate risks.

- Report any accidents or near-misses promptly and assist in investigations to prevent recurrence.

4. Collaboration and Communication

Effective communication and collaboration are key. You will be part of a team and interact with various individuals.

- Communicate with drilling crews to relay drilling fluid parameters and provide timely updates on fluid conditions.

- Collaborate with engineers and geologists to optimize drilling fluid properties based on well conditions and drilling objectives.

- Maintain accurate records and documentation regarding mud mill operations and drilling fluid management.

Interview Tips

Preparing thoroughly for your interview is crucial. Here are some tips to help you ace it:

1. Research and Know the Company

Take the time to research the mud mill company you’re applying to. Understand their mission, values, and industry reputation.

- Visit their website, read their company profile, and check their social media presence.

- Identify key people in the company and learn about their experiences and expertise.

- Research the specific mud mill you’ll be operating and its capabilities.

2. Highlight Your Skills and Experience

Focus on showcasing your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible.

- Emphasize your proficiency in operating mud mills and handling drilling fluids.

- Provide examples of how you’ve maintained and repaired drilling equipment effectively.

- Highlight your understanding of drilling fluid properties and how you’ve optimized them for different well conditions.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Tell me about your experience operating a mud mill. Describe a challenging situation you faced and how you overcame it.

- How do you ensure the safety of yourself and others while working at a mud mill?

- Give me an example of when you successfully collaborated with a drilling crew to optimize drilling fluid performance.

4. Dress Professionally and Be Punctual

First impressions matter, so dress professionally and arrive for your interview on time. Be polite and respectful to everyone you meet.

- Wear clean, ironed clothes that are appropriate for an industrial setting.

- Arrive at the interview location a few minutes early to demonstrate punctuality and respect for the interviewer’s time.

- Maintain a positive and confident demeanor throughout the interview.

Next Step:

Now that you’re armed with the knowledge of Mud Mill Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mud Mill Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini