Are you gearing up for a career in Mulling Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mulling Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

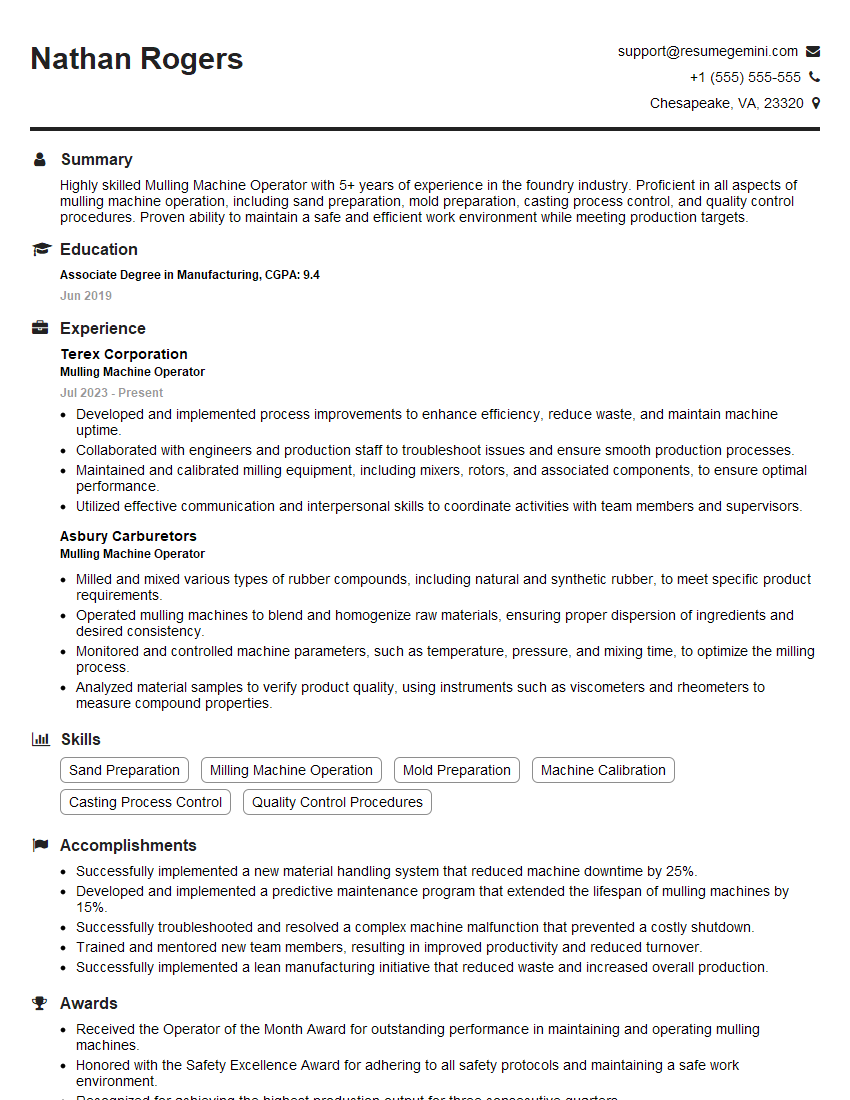

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mulling Machine Operator

1. What are the key steps involved in operating a mulling machine?

The key steps involved in operating a mulling machine include:

- Loading the materials into the mixing chamber

- Setting the mulling temperature and time

- Starting the machine and monitoring the process

- Unloading the mixed materials

- Cleaning and maintaining the machine

2. How do you ensure that the mulling process is carried out correctly?

Quality control measures

- Checking the raw materials for quality

- Calibrating the machine regularly

- Monitoring the process parameters closely

- Inspecting the mixed materials for defects

Preventive maintenance

- Cleaning the machine regularly

- Lubricating the moving parts

- Checking the belts and pulleys for wear and tear

- Inspecting the electrical components for damage

3. What are the potential hazards associated with operating a mulling machine?

The potential hazards associated with operating a mulling machine include:

- Exposure to hazardous chemicals

- Risk of burns from the hot materials

- Risk of injuries from moving parts

- Risk of electrical shock

- Risk of fire or explosion

4. How do you handle a situation where the mulling machine is not functioning properly?

If the mulling machine is not functioning properly, I would first try to identify the problem by checking the following:

- The power supply

- The electrical connections

- The mechanical components

- The process parameters

Once I have identified the problem, I would then take steps to correct it. If I am unable to fix the problem myself, I would contact a qualified technician for assistance.

5. What are the different types of materials that can be mixed in a mulling machine?

The different types of materials that can be mixed in a mulling machine include:

- Rubber

- Plastics

- Metals

- Ceramics

- Foodstuffs

6. What are the advantages of using a mulling machine over other mixing methods?

The advantages of using a mulling machine over other mixing methods include:

- More efficient mixing

- More uniform mixing

- Less chance of contamination

- Ability to mix a wider variety of materials

- Lower energy consumption

7. How do you maintain the mulling machine to ensure its optimal performance?

To maintain the mulling machine and ensure its optimal performance, I would perform the following tasks:

- Clean the machine regularly

- Lubricate the moving parts

- Check the belts and pulleys for wear and tear

- Inspect the electrical components for damage

- Calibrate the machine regularly

- Follow the manufacturer’s instructions for maintenance

8. What are the safety precautions that should be taken when operating a mulling machine?

The safety precautions that should be taken when operating a mulling machine include:

- Wearing appropriate personal protective equipment (PPE)

- Keeping the work area clean and free of obstructions

- Following the manufacturer’s instructions for operating the machine

- Never operating the machine if it is not functioning properly

- Being aware of the potential hazards associated with the machine

9. How do you troubleshoot common problems that may occur with a mulling machine?

Some common problems that may occur with a mulling machine include:

- The machine is not starting

- The machine is not mixing properly

- The machine is overheating

- The machine is leaking

- The machine is making strange noises

To troubleshoot these problems, I would first try to identify the cause of the problem by checking the following:

- The power supply

- The electrical connections

- The mechanical components

- The process parameters

Once I have identified the cause of the problem, I would then take steps to correct it. If I am unable to fix the problem myself, I would contact a qualified technician for assistance.

10. What are the latest trends in mulling machine technology?

The latest trends in mulling machine technology include:

- The use of automation to improve efficiency and safety

- The development of new materials that can be mixed in a mulling machine

- The use of new technologies to improve the quality of the mixing process

- The development of new mulling machines that are more energy-efficient and environmentally friendly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mulling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mulling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mulling Machine Operator is responsible for the proper functioning of the mulling machine, a critical piece of equipment in the foundry industry. Their primary tasks involve:

1. Machine Operation

The operator is responsible for:

- Loading raw materials (sand, clay, binders, and additives) into the mulling machine

- Setting machine parameters and initiating the mixing process

- Monitoring the mixing process and making adjustments as needed to ensure proper material properties

2. Quality Control

The operator is responsible for:

- Sampling and testing the mixed material

- Performing quality checks to ensure the material meets the specified requirements

- Maintaining detailed records of the mixing process for future reference

3. Machine Maintenance

The operator is responsible for:

- Daily cleaning and maintenance of the mulling machine

- Identifying and resolving minor machine issues

- Reporting major machine problems to the supervisor or maintenance team

4. Safety

The operator is responsible for maintaining a safe working environment by:

- Following all safety protocols and procedures

- Wearing appropriate personal protective equipment (PPE)

- Keeping the work area clean and free from hazards

Interview Tips

To ace an interview for a Mulling Machine Operator position, candidates should consider the following tips:

1. Research the Company and the Role

Candidates should thoroughly research the company they are applying to, including their industry, products, and values. They should also thoroughly review the job description to understand the specific responsibilities and requirements of the role.

2. Highlight Relevant Skills and Experience

Candidates should highlight their skills and experience that are directly relevant to the job. For example, they should emphasize their knowledge of mulling machine operation, quality control procedures, and safety protocols. If they have previous experience working with similar machinery or in the foundry industry, they should be sure to mention it.

3. Demonstrate Problem-Solving Abilities

Interviewers will want to know that candidates can identify and resolve problems that may arise during the mulling process. Candidates should provide examples of times when they have successfully solved problems related to machines or production processes.

4. Emphasize Teamwork and Communication Skills

Mulling Machine Operators often work as part of a team, so candidates should demonstrate their teamwork and communication skills. They should highlight their ability to work effectively with others, communicate clearly, and resolve conflicts amicably.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that candidates are engaged and interested in the position. Candidates should prepare questions that demonstrate their knowledge of the company, the role, or the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mulling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mulling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.