Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Multi-Operation Forming Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

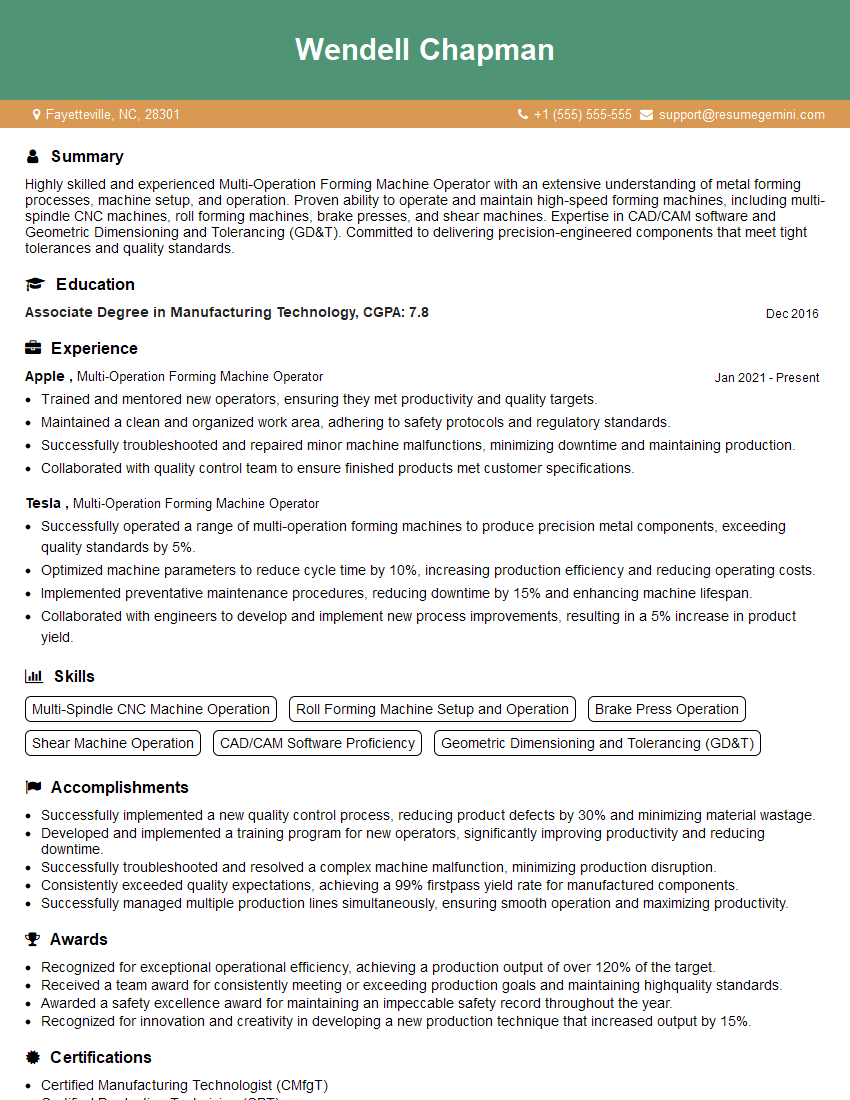

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multi-Operation Forming Machine Operator

1. How do you ensure the accuracy of the parts produced by the multi-operation forming machine?

- Regularly calibrate the machine according to the manufacturer’s specifications.

- Use precision measuring tools to inspect the parts for dimensional accuracy.

- Implement statistical process control techniques to monitor and maintain production quality.

2. Describe the process of setting up and operating a multi-operation forming machine.

- Select the appropriate material for the job.

- Cut the material to the desired length.

- Mount the correct tooling on the machine.

- Adjust the machine settings for the desired part shape and size.

- Load the material into the machine.

- Start the machine and monitor the forming process.

- Unload the finished part and inspect it for quality.

Material Preparation

Machine Setup

Operation

3. How do you troubleshoot common problems that may occur during the multi-operation forming process?

- Material jamming: Check for obstructions in the material path, adjust machine settings.

- Tool breakage: Inspect the tools for wear or damage, replace as necessary.

- Dimensional inaccuracies: Recalibrate the machine, verify tooling alignment, check material properties.

4. Explain the importance of preventive maintenance for a multi-operation forming machine.

- Reduces downtime due to unexpected breakdowns.

- Extends the machine’s lifespan and improves operating efficiency.

- Ensures consistent product quality and reduces scrap rates.

5. How do you stay updated on the latest advancements in multi-operation forming technology?

- Attend industry conferences and exhibitions.

- Read technical journals and publications.

- Consult with machine manufacturers and industry experts.

6. Describe how you prioritize tasks and manage your time effectively in a fast-paced production environment.

- Use a to-do list or project management software.

- Break down large tasks into smaller, manageable ones.

- Delegate tasks to other team members when appropriate.

7. Explain how you ensure safety when operating a multi-operation forming machine.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols and procedures.

- Inspect the machine and work area for hazards before starting operation.

8. How do you handle situations where the machine produces non-conforming parts?

- Stop the machine immediately.

- Identify the cause of the non-conformance.

- Take corrective action to prevent further production of non-conforming parts.

- Document the incident and report it to the supervisor.

9. Describe your experience with different types of metalworking fluids and lubricants.

- Properties and applications of cutting fluids, coolants, and lubricants.

- Methods for selecting and applying fluids based on material and machine.

- Importance of proper fluid maintenance and disposal.

10. Explain how you measure and maintain the sharpness of cutting tools used in the multi-operation forming process.

- Use a tool microscope or other measuring device to assess sharpness.

- Follow manufacturer’s recommendations for tool maintenance.

- Monitor tool wear during operation and replace when necessary.

- Use proper tool handling and storage techniques to prevent damage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multi-Operation Forming Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multi-Operation Forming Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Multi-Operation Forming Machine Operators are responsible for operating and maintaining multi-operation forming machines to manufacture metal or plastic parts. Their key responsibilities include:

1. Machine Operation:

Operating multi-operation forming machines to shape and form metal or plastic materials into desired parts.

- Setting up and adjusting machines according to specifications and blueprints.

- Monitoring and controlling machine operation to ensure accurate production and minimize waste.

2. Tooling and Maintenance:

Installing, maintaining, and adjusting tooling and fixtures used in the forming process.

- Inspecting and replacing worn or damaged tooling to ensure optimal performance.

- Performing routine maintenance and troubleshooting to minimize downtime and increase productivity.

3. Quality Control:

Monitoring and inspecting parts produced by the forming machines to ensure they meet specifications.

- Using measuring instruments and gauges to verify dimensions and tolerances.

- Identifying and correcting any deviations from quality standards.

4. Material Handling:

Loading and unloading raw materials and finished parts from the forming machines.

- Ensuring proper material flow to maximize efficiency and minimize waste.

- Maintaining a clean and organized work area to facilitate safe and efficient operations.

Interview Tips

Preparing for an interview for a Multi-Operation Forming Machine Operator position requires thorough research and understanding of the job responsibilities. Here are some tips to help candidates ace the interview:

1. Research the Company and Position:

Gather information about the company’s products, services, and industry. Learn about the specific requirements of the Multi-Operation Forming Machine Operator role, including the technologies and equipment used.

- Visit the company website and social media pages.

- Read industry news and articles about forming machines and techniques.

2. Highlight Relevant Skills and Experience:

Emphasize your experience in operating and maintaining multi-operation forming machines. Showcase your understanding of tooling, quality control, and material handling processes.

- Quantify your accomplishments using specific examples and metrics.

- Be prepared to discuss your ability to work with different materials and adhere to quality standards.

3. Demonstrate Problem-Solving Abilities:

Interviewers will evaluate your ability to troubleshoot and solve problems that may arise during the forming process. Provide examples of situations where you identified and resolved issues independently.

- Describe how you diagnose and fix common problems with forming machines.

- Explain your approach to minimizing downtime and maintaining productivity.

4. Emphasize Safety and Attention to Detail:

Multi-Operation Forming Machine Operators must adhere to strict safety protocols. Highlight your commitment to safety and your ability to work meticulously.

- Discuss your knowledge of machine safety procedures and regulations.

- Explain how you ensure accuracy and consistency in the forming process.

Next Step:

Now that you’re armed with the knowledge of Multi-Operation Forming Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Multi-Operation Forming Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini