Are you gearing up for an interview for a Multi Operation Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Multi Operation Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

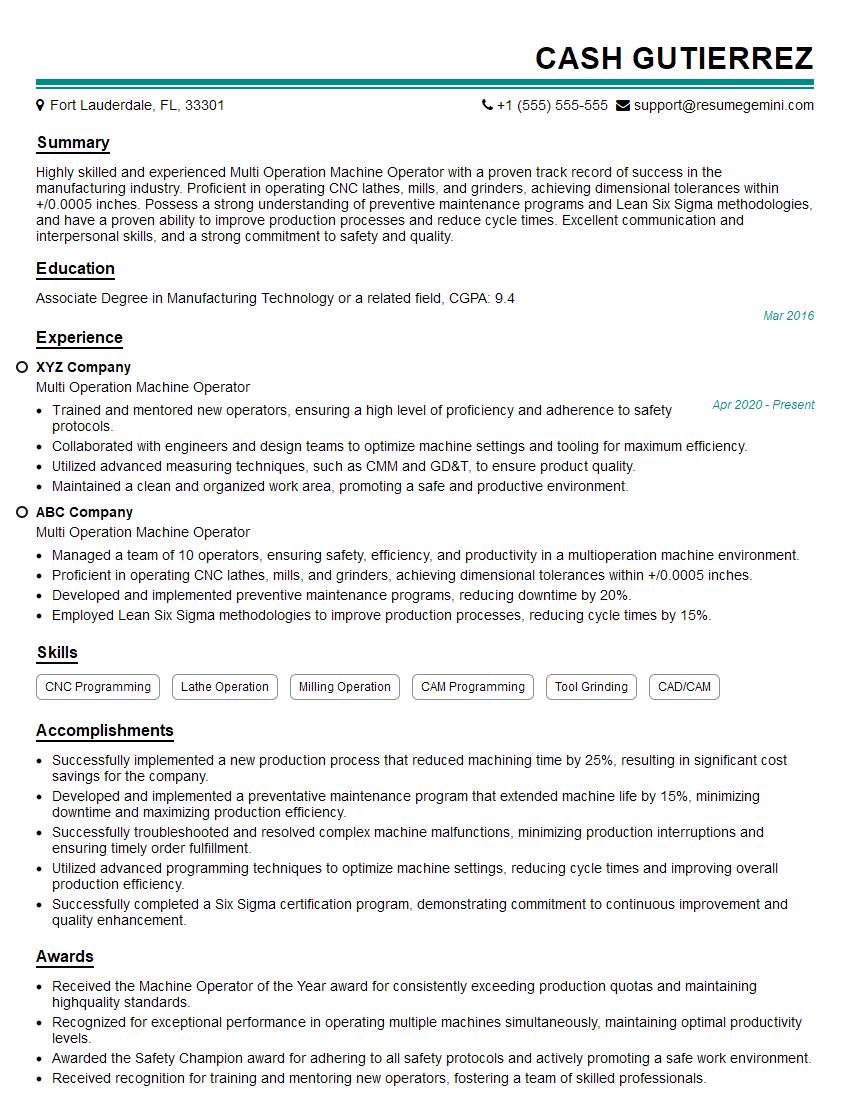

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multi Operation Machine Operator

1. What are the key responsibilities of a Multi Operation Machine Operator?

As a Multi Operation Machine Operator, I would be responsible for a wide range of duties, including:

- Setting up and operating multi-operation machines

- Monitoring machine performance and making adjustments

- Inspecting finished products for quality

- Maintaining machinery and making minor repairs

- Following safety procedures and regulations

2. What are the different types of multi-operation machines that you have experience with?

CNC Machines

- Computer Numerical Control (CNC) machines are advanced machines that use computer-aided design (CAD) software to control the movement of the machine.

- I have experience operating CNC lathes, mills, and grinders.

Manual Machines

- Manual machines are controlled by the operator’s hand movements.

- I have experience operating manual lathes, mills, and drill presses.

3. What is your experience with programming CNC machines?

I have experience programming CNC machines using G-code and M-code.

- G-code controls the movement of the machine

- M-code controls the auxiliary functions of the machine, such as spindle speed and coolant flow

I am proficient in using CAM software to generate G-code and M-code programs.

4. What are the different types of materials that you have experience with?

- Metals

- Plastics

- Wood

- Composites

I have experience machining a variety of metals, including steel, aluminum, and stainless steel.

I also have experience machining plastics, wood, and composites.

I am familiar with the different properties of each material and know how to machine them to achieve the desired results.

5. What are the different types of tolerances that you have experience with?

- Tight tolerances

- Medium tolerances

- Loose tolerances

I have experience working with tight tolerances, medium tolerances, and loose tolerances.

I understand the importance of maintaining tight tolerances for critical applications.

I also understand the importance of being able to work with medium and loose tolerances for less critical applications.

6. What is your experience with quality control?

I have experience with all aspects of quality control, including:

- Performing inspections

- Identifying and correcting defects

- Maintaining quality records

I am familiar with the different quality standards and specifications.

I am also familiar with the different quality control tools and techniques.

7. What is your experience with safety?

I am committed to safety and follow all safety procedures and regulations.

- I am familiar with the different hazards associated with operating multi-operation machines.

- I know how to properly use safety equipment.

- I am always aware of my surroundings and the people around me.

8. What is your experience with teamwork?

I am a team player and work well with others.

- I am always willing to help out my co-workers.

- I am good at communicating with others and resolving conflicts.

- I am always willing to learn new things.

9. What is your availability?

I am available to work full-time.

I am flexible and can work overtime if needed.

10. What are your salary expectations?

My salary expectations are negotiable.

I am confident that I can add value to your company and I am willing to work hard to earn a fair wage.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multi Operation Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multi Operation Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Multi Operation Machine Operator is responsible for operating and maintaining a variety of computerized numerical control (CNC) machines to manufacture precision parts and products. The key job responsibilities include:

1. Machine Operation

Setting up and operating CNC machines, such as lathes, mills, and grinders, to produce parts and products according to specifications.

- Interpret technical drawings and blueprints to determine machining parameters.

- Select and install appropriate cutting tools and fixtures.

2. Quality Control

Monitoring and inspecting parts and products during production to ensure compliance with quality standards.

- Using precision measuring instruments and gauges to verify dimensions and tolerances.

- Identifying and correcting any deviations from specifications.

3. Machine Maintenance

Performing routine maintenance and troubleshooting on CNC machines to ensure optimal performance.

- Lubricating moving parts, checking for leaks, and replacing worn components.

- Diagnosing and resolving machine issues, such as tool breakage or software errors.

4. Equipment and Tooling Management

Ensuring the availability and proper use of equipment and tooling required for production.

- Maintaining an organized and clean workspace.

- Ordering and managing inventory of cutting tools, fixtures, and other materials.

Interview Tips

Preparing for an interview for a Multi Operation Machine Operator position requires a combination of technical knowledge and communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and products/services. Review the job description thoroughly to understand the specific responsibilities and qualifications required.

- Visit the company’s website and LinkedIn page.

- Look for news articles or press releases about the company’s recent developments.

2. Highlight Your Technical Skills and Experience

Emphasize your proficiency in operating and maintaining CNC machines, including your knowledge of specific software and programming languages. Showcase your ability to read technical drawings and blueprints, and demonstrate your understanding of quality control procedures.

- Quantify your accomplishments by providing specific examples of your work.

- Mention any certifications or training you have in CNC machining or related fields.

3. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivations. Prepare concise and well-structured responses that highlight your strengths as a Multi Operation Machine Operator.

- Tell me about your experience in operating CNC machines.

- How do you ensure the quality of your work?

- What are some of the challenges you have faced as a Multi Operation Machine Operator?

4. Show Your Enthusiasm and Motivation

Convey your passion for manufacturing and your desire to contribute to the company’s success. Express your eagerness to learn and grow in the role, and demonstrate your commitment to delivering high-quality work.

- Share your knowledge of industry trends and advancements.

- Ask insightful questions about the company’s operations and growth plans.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare relevant questions about the company’s manufacturing processes, the team you would be working with, or the company’s commitment to employee development.

- What are the company’s quality standards for manufactured parts?

- What opportunities are there for career advancement within the company?

- How does the company support employee training and skill development?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Multi Operation Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!