Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Multilith Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

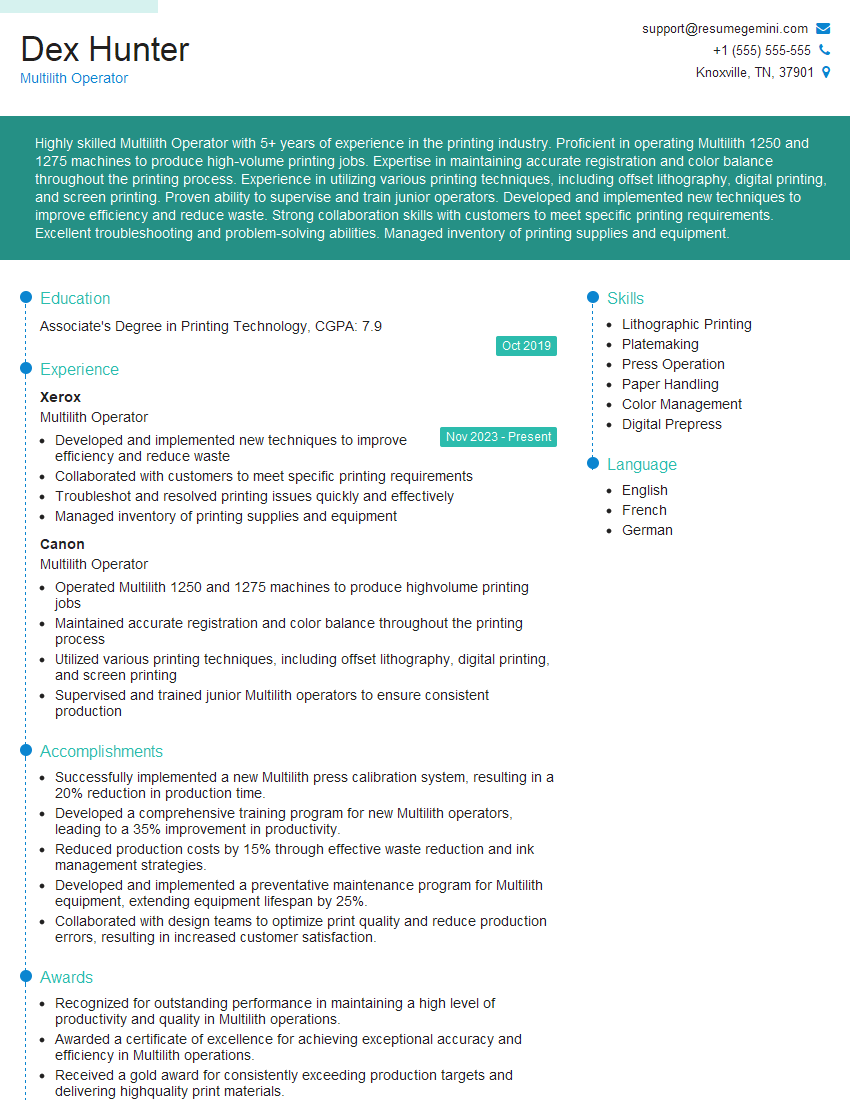

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multilith Operator

1. How do you ensure the accuracy of registration when operating a multilith machine?

To ensure accuracy in registration, I follow a systematic approach:

- Plate Preparation: I meticulously inspect the film for any defects and ensure it is correctly positioned on the plate.

- Machine Setup: I carefully align the plate cylinder and impression cylinder to the marks on the machine.

- Paper Loading: I adjust the paper guide to match the plate size and ensure the paper is fed squarely into the machine.

- Printing: I closely monitor the printed sheets during the initial run and make any necessary adjustments to the registration controls.

2. Describe the process of troubleshooting and resolving common Multilith machine errors.

Paper Feeding Issues

- Check if there is sufficient paper in the feed tray.

- Examine the paper path for any obstructions or misalignments.

Image Quality Issues

- Inspect the plate for scratches or damage.

- Adjust the ink levels and fountain settings.

- Clean the rollers and blankets to remove any debris.

Printing Problems

- Verify that the correct plate is loaded.

- Check the impression settings and adjust accordingly.

- Troubleshoot any electrical issues or mechanical malfunctions.

3. How do you maintain and clean a Multilith machine to ensure optimal performance?

To maintain and clean a Multilith machine, I follow a comprehensive routine:

- Daily Maintenance:

- Inspect and clean the rollers, blankets, and impression cylinder.

- Wipe away any ink or debris from the printing table.

- Weekly Maintenance:

- Thoroughly clean the ink fountain and ink lines.

- Inspect and replace any worn or damaged parts.

- Monthly Maintenance:

- Lubricate moving parts according to the manufacturer’s recommendations.

- Perform a comprehensive check of the machine’s electrical system.

4. Explain the different types of paper stocks used with a Multilith machine and their suitability for various printing applications.

There is a wide range of paper stocks compatible with a Multilith machine, each with its own characteristics and suitability for specific printing applications:

- Uncoated Papers: These papers have a natural surface and are suitable for general-purpose printing, such as letterheads and brochures.

- Coated Papers: These papers have a smooth, glossy surface and provide better image reproduction, making them ideal for high-quality prints, such as catalogs and magazines.

- Specialty Papers: These papers come in various textures, colors, and finishes and are used for specialized printing applications, such as invitations or greeting cards.

5. How do you calculate the ink coverage for a given print job and determine the appropriate ink/water balance?

To calculate ink coverage, I use the following formula:

Ink Coverage (%) = (Ink Area / Total Print Area) x 100

Based on the calculated ink coverage, I adjust the ink/water balance to achieve the desired print quality. Too much ink can lead to smudging or overinking, while too much water can result in faint or blurry prints.

6. Describe the safety precautions you observe while operating a Multilith machine.

Safety is paramount when operating a Multilith machine. I adhere to the following precautions:

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure the machine is properly grounded and has adequate ventilation.

- Never reach into the machine while it is running.

- Keep flammable materials away from the machine.

- Follow proper waste disposal procedures for ink and solvents.

7. How do you handle and store plates for a Multilith machine to ensure their longevity?

To ensure the longevity of plates for a Multilith machine, I follow these guidelines:

- Store plates in a cool, dry place, away from direct sunlight.

- Avoid touching the plate surface directly; use gloves or clean tweezers.

- Clean plates thoroughly after use with a mild solvent and a soft cloth.

- Do not stack plates on top of each other without proper spacers.

- Inspect plates regularly for scratches or damage and repair or replace them as needed.

8. Explain the purpose and function of the dampening system in a Multilith machine.

The dampening system in a Multilith machine plays a crucial role in the printing process:

- Controls Moisture: It provides a controlled amount of water to the printing plate, which prevents the ink from sticking to the non-image areas.

- Maintains Ink Balance: The dampening system ensures that the right amount of water is present on the plate to balance the ink and achieve optimal printing quality.

- Prevents Plate Oxidation: The water film protects the plate from oxidation, extending its lifespan.

9. How do you adjust the impression pressure on a Multilith machine to achieve the desired print quality?

Adjusting the impression pressure on a Multilith machine is essential for achieving the desired print quality:

- Too little pressure can result in light or faded prints.

- Too much pressure can cause ink squash or embossing.

I follow these steps to adjust the impression pressure:

- Run a test print.

- Examine the print for any signs of under or over impression.

- Adjust the impression screws accordingly.

- Repeat the process until the desired print quality is achieved.

10. What troubleshooting steps would you take if you encounter ghosting or double printing on a Multilith print job?

Ghosting or double printing on a Multilith print job can be caused by various factors. To troubleshoot, I would:

- Check Plate Alignment: Ensure the plate is correctly positioned and aligned on the machine.

- Inspect Impression Cylinder: Examine the impression cylinder for any damage or debris that could cause double impressions.

- Adjust Dampening System: Improper dampening can lead to ghosting. Check the water fountain and adjust the water flow accordingly.

- Clean the Rollers: Dirty rollers can transfer residual ink to the paper, causing double printing.

- Reset Machine Settings: Sometimes, a simple machine reset can resolve ghosting issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multilith Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multilith Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Multilith Operator is responsible for operating and maintaining a Multilith printing press. The primary duties include:

1. Machine Operation

Preparing and setting up the Multilith press

- Loading paper and adjusting the press settings

- Checking the press for proper operation and making necessary adjustments

2. Printing Process

Printing the desired images or documents

- Feeding the paper through the press

- Monitoring the print quality and making adjustments as needed

3. Maintenance and Troubleshooting

Maintaining the proper functioning of the Multilith press

- Cleaning the press and replacing worn parts

- Troubleshooting and resolving any operational issues

4. Quality Control

Ensuring the quality of the printed materials

- Inspecting the printed output for errors and defects

- Making adjustments to the printing process to ensure optimal quality

Interview Tips

To prepare for an interview for a Multilith Operator position, it is essential to:

1. Research the Company and Position

Review the company website and social media profiles to gain insights into their culture, products, and services. Understand the specific requirements and responsibilities of the Multilith Operator role.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating Multilith printing presses. Showcase your knowledge of printing techniques and quality control procedures. Highlight any previous experience in a similar role or your ability to perform tasks related to machine operation, maintenance, and quality control.

3. Practice Common Interview Questions

Anticipate common interview questions related to your skills, experience, and motivation. Prepare thoughtful responses that demonstrate your abilities and enthusiasm for the role. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Be Prepared to Discuss Troubleshooting Experience

Interviewers may ask about your experience in troubleshooting and resolving printing issues. Provide specific examples of how you identified and resolved problems efficiently.

5. Demonstrate Attention to Detail and Accuracy

Multilith Operators have a keen eye for detail and a commitment to accuracy. During the interview, emphasize your attention to quality and your ability to produce high-quality printed materials consistently.

Next Step:

Now that you’re armed with the knowledge of Multilith Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Multilith Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini