Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Multiple Coil Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

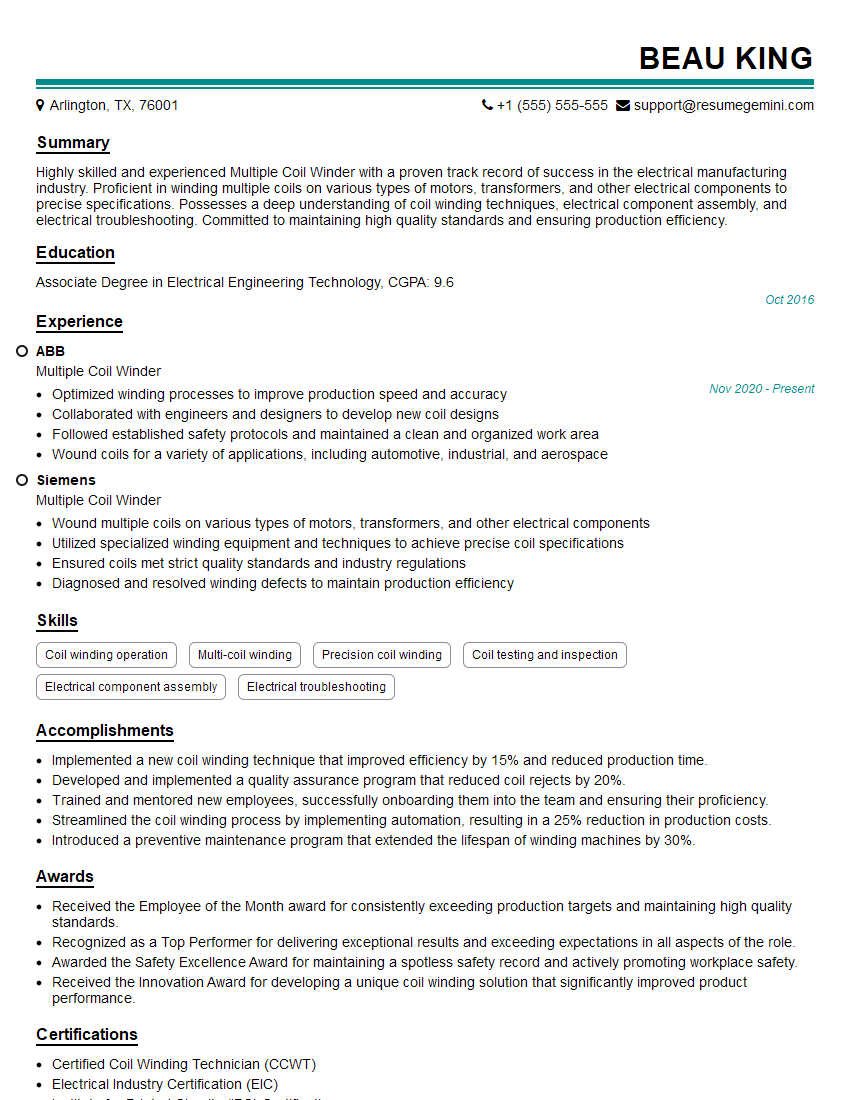

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Multiple Coil Winder

1. Explain the process of winding multiple coils on a stator?

The process of winding multiple coils on a stator involves the following steps:

- Prepare the stator core by cleaning and inspecting it for any defects.

- Insert the coil formers into the stator slots.

- Wind the coils onto the coil formers, ensuring that the turns are evenly distributed and the insulation is not damaged.

- Connect the coils in series or parallel, depending on the desired electrical characteristics.

- Insulate the coils with varnish or other materials to protect them from electrical shorts.

- Test the coils for continuity and insulation resistance to ensure they meet specifications.

2. What are the different types of coil winding machines?

Manual coil winding machines

- Require an operator to manually guide the wire onto the coil form.

- Suitable for small-scale production or prototype development.

Semi-automatic coil winding machines

- Combine manual operation with automated features, such as wire feeding and tension control.

- Increase productivity and improve consistency.

Fully automatic coil winding machines

- Perform the entire winding process without human intervention.

- Used for high-volume production and complex coil designs.

3. How do you ensure that the coils are evenly wound?

- Use a tension control device to maintain consistent wire tension.

- Employ a traverse mechanism to ensure even distribution of turns across the coil former.

- Check the coil diameter and pitch regularly using measuring tools.

- Utilize automated winding machines with precise control systems.

4. What types of insulation materials are used in coil winding?

- Enamel (polyurethane, polyester)

- Varnish (epoxy, acrylic)

- Paper (kraft, Nomex)

- Mylar (polyethylene terephthalate)

- Kapton (polyimide)

5. How do you test the quality of wound coils?

- Continuity test: Checks for any breaks or shorts in the coil windings.

- Insulation resistance test: Measures the resistance between the windings and the core or frame.

- Hi-pot test: Applies a high voltage to the coil to test for insulation breakdown.

- Inductance test: Measures the inductance of the coil to ensure it meets specifications.

6. What are the common defects that can occur during coil winding?

- Shorted turns: Turns that touch each other and cause a short circuit.

- Open turns: Turns that are broken or not connected.

- Skewed winding: Coils that are not evenly distributed across the coil former.

- Loose winding: Coils that are not tightly wound and can move.

- Damaged insulation: Insulation that is torn or punctured.

7. How do you troubleshoot and repair coil winding defects?

- Shorted turns: Identify the shorted turns and remove them or insulate them.

- Open turns: Locate the broken turns and reconnect them.

- Skewed winding: Rewind the coil evenly across the coil former.

- Loose winding: Tighten the windings and secure them with varnish or tape.

- Damaged insulation: Repair or replace the damaged insulation.

8. What are the safety precautions to follow when working with coil winding machines?

- Wear appropriate safety gear (gloves, safety glasses, hearing protection).

- Ensure the machine is properly grounded.

- Keep loose clothing and jewelry away from moving parts.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s instructions for safe operation and maintenance.

9. How do you maintain and calibrate coil winding machines?

- Regularly clean and lubricate moving parts.

- Check and adjust tension control devices.

- Calibrate the machine using standard test coils.

- Follow the manufacturer’s recommended maintenance schedule.

10. Describe your experience in winding coils for different applications.

I have experience in winding coils for a variety of applications, including:

- Electric motors

- Generators

- Transformers

- Inductors

- Solenoids

I am familiar with the different types of coil winding machines and the techniques required to produce high-quality coils that meet specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Multiple Coil Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Multiple Coil Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Multiple Coil Winders are responsible for operating and maintaining coil winding machines and producing coils for various applications. Their key responsibilities include:

1. Coil Winding

Wind coils precisely according to specifications and drawings

- Set up and operate coil winding machines, adjusting tension, speed, and wire feed

- Monitor winding process, checking for errors and making adjustments as needed

2. Machine Maintenance

Perform routine maintenance and calibrate coil winding machines

- Inspect machines for wear and tear, and replace or repair components

- Lubricate and clean machines to ensure smooth operation

3. Quality Control

Inspect and test coils to ensure they meet specifications

- Measure coil dimensions, resistance, and inductance

- Identify and correct any defects or inconsistencies

4. Production Management

Monitor production schedules and meet deadlines

- Plan and organize coil winding operations to maximize efficiency

- Work with team members to resolve production issues

Interview Tips

To ace an interview for a Multiple Coil Winder position, consider the following tips:

1. Research the Company and Position

Demonstrate your interest and knowledge of the company and the role.

- Review the company website, social media, and news articles to understand their industry, products, and culture.

- Thoroughly read the job description to identify the key skills and responsibilities required.

2. Prepare Relevant Skills and Experience

Highlight your technical skills and hands-on experience in coil winding.

- Emphasize your ability to operate and maintain coil winding machines, including specific models and types.

- Showcase your proficiency in coil winding techniques, such as manual, semi-automatic, or automatic winding.

- Provide examples of your experience in quality control, inspection, and troubleshooting.

3. Practice Common Interview Questions

Prepare for typical interview questions and tailor your answers to the job role.

- Explain your understanding of the coil winding process and the different types of coils you have worked with.

- Describe your experience in troubleshooting and resolving machine issues.

- Provide examples of your ability to meet production targets and work efficiently in a team environment.

4. Enthusiasm and Passion

Convey your enthusiasm for the field and passion for coil winding.

- Explain why you are interested in this position and what motivates you as a Multiple Coil Winder.

- Share any relevant projects, hobbies, or interests that demonstrate your passion for coil winding.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Multiple Coil Winder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.