Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the MVA Reactor Operator (Monovinylacetylene Reactor Operator) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a MVA Reactor Operator (Monovinylacetylene Reactor Operator) so you can tailor your answers to impress potential employers.

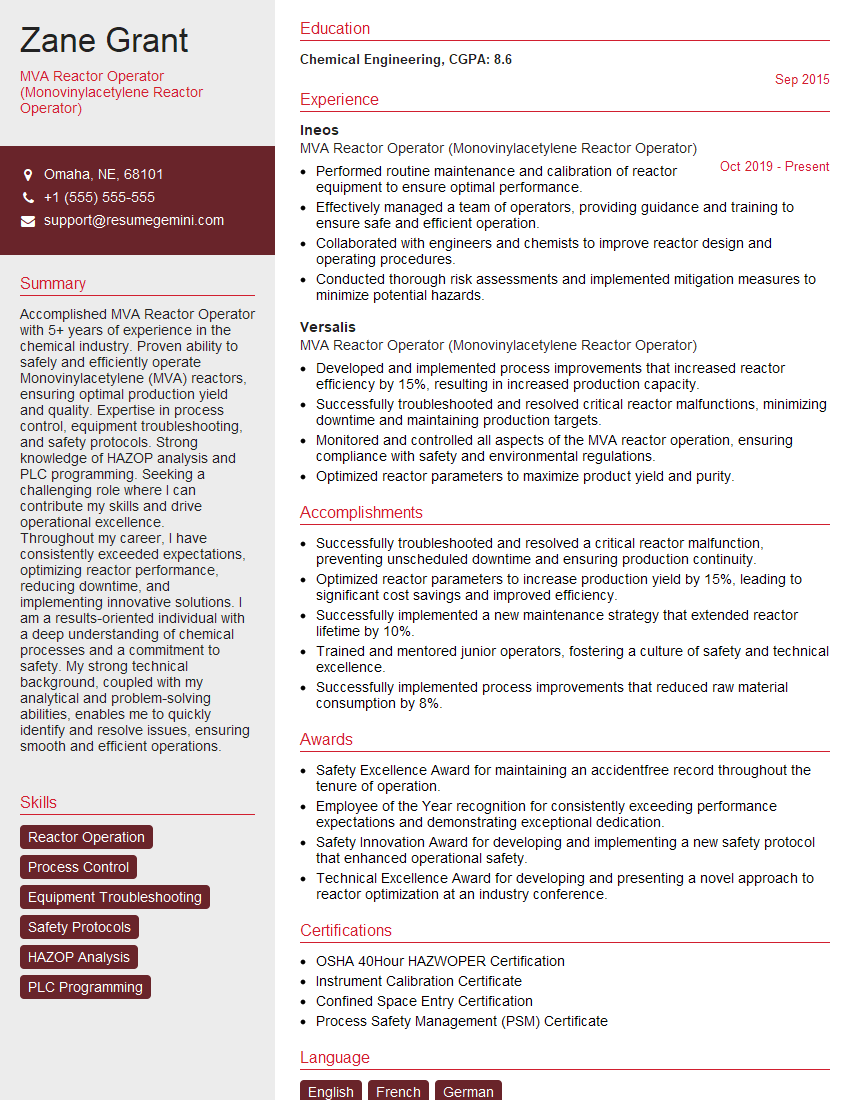

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For MVA Reactor Operator (Monovinylacetylene Reactor Operator)

1. What are the key responsibilities of an MVA Reactor Operator?

As an MVA Reactor Operator, I would be responsible for the safe and efficient operation of the monovinylacetylene (MVA) reactor unit. My primary duties would include:

- Monitoring and controlling reactor parameters such as temperature, pressure, flow rates, and catalyst activity

- Performing routine inspections and maintenance of the reactor and associated equipment

- Responding to process upsets and taking corrective actions to ensure stable operation

- Maintaining accurate records and documentation of reactor operations

- Complying with all safety regulations and procedures

2. How do you ensure the quality of the MVA product?

Process Monitoring and Control

- Continuously monitor key process parameters to identify any deviations from specifications

- Adjust process conditions as needed to optimize product quality and yield

Regular Inspections and Maintenance

- Conduct regular inspections of the reactor and equipment to identify potential issues

- Perform preventive maintenance to minimize the risk of breakdowns and ensure consistent product quality

Analysis and Corrective Actions

- Analyze product samples to ensure they meet specifications

- Implement corrective actions promptly to address any quality deviations

Quality Assurance

- Adhere to established quality assurance procedures and protocols

- Maintain accurate records of all quality-related activities

3. Describe the safety precautions you would take when operating the MVA reactor.

Safety is paramount in MVA reactor operations. I would strictly adhere to the following precautions:

- Wear appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, and safety glasses

- Follow established operating procedures and safety protocols

- Monitor critical process parameters continuously to identify potential hazards

- Be aware of potential risks and take appropriate measures to mitigate them

- Maintain a clean and organized work area

- Communicate effectively with colleagues and supervisors to ensure coordination and awareness

- Receive regular safety training and participate in emergency drills

4. What are the environmental considerations associated with MVA reactor operations?

MVA reactor operations have certain environmental implications which I am aware of:

- Emission of volatile organic compounds (VOCs): MVA production can result in the release of VOCs, which can contribute to air pollution and ozone formation

- Wastewater generation: The reactor process generates wastewater that requires proper treatment to remove contaminants and meet environmental regulations

- Solid waste disposal: Catalyst and other materials used in the process may generate solid waste that needs to be disposed of responsibly

Environmental Mitigation Strategies

- Comply with all applicable environmental regulations

- Implement pollution control measures, such as scrubbers and incinerators

- Monitor emissions and wastewater discharge regularly

- Optimize process conditions to minimize waste generation

5. What troubleshooting steps would you take if the MVA reactor is experiencing a drop in product yield?

If the MVA reactor is experiencing a drop in product yield, I would take the following troubleshooting steps:

- Check process parameters (temperature, pressure, flow rates) to identify any deviations

- Examine the catalyst activity and replace it if necessary

- Inspect reactor components for any leaks or blockages

- Review feedstock quality and make adjustments if needed

- Consult with colleagues and supervisors to discuss possible causes and solutions

6. How do you handle process upsets and emergency situations?

In the event of a process upset or emergency situation, I would follow these steps:

- Remain calm and assess the situation quickly

- Identify the root cause of the issue and take immediate action to stabilize the process

- Communicate with colleagues, supervisors, and emergency responders as necessary

- Implement emergency procedures and follow safety protocols

- Document the incident and take appropriate corrective measures to prevent recurrence

7. What are the latest advancements in MVA reactor technology that you are aware of?

I am actively aware of the latest advancements in MVA reactor technology, including:

- Development of new catalysts with higher activity and selectivity

- Implementation of advanced process control systems for improved efficiency and yield

- Research on sustainable and environmentally friendly MVA production methods

- Exploration of alternative feedstocks for MVA synthesis

8. How do you stay updated on the latest industry best practices and technological developments?

To stay updated on the latest industry best practices and technological developments, I engage in continuous learning and development activities:

- Attend industry conferences, workshops, and seminars

- Read technical journals and publications

- Participate in online forums and discussion groups

- Consult with experts and colleagues in the field

- Take advantage of training opportunities provided by my organization and professional associations

9. What is your understanding of the role of an MVA reactor in the production of downstream products?

MVA reactor plays a crucial role in the production of downstream products, particularly in the manufacturing of polymers and plastics:

- MVA is a key intermediate in the production of polyvinyl acetate (PVAc), an essential component in paints, adhesives, and textiles

- It is also used as a raw material for the synthesis of polyvinyl alcohol (PVA), which finds applications in films, fibers, and packaging

- Furthermore, MVA is a precursor for the production of polyvinyl chloride (PVC), a widely used plastic material in construction, automotive, and consumer products

10. How do you prioritize your responsibilities and manage your time effectively when operating the MVA reactor?

Prioritizing responsibilities and managing time effectively is essential for successful MVA reactor operations. I follow these strategies:

- Establish clear priorities based on criticality and urgency

- Create a structured work schedule and stick to it as much as possible

- Delegate tasks to colleagues when appropriate to optimize efficiency

- Utilize technology tools for task management and communication

- Take regular breaks to maintain focus and productivity

- Communicate any potential delays or challenges to supervisors in a timely manner

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for MVA Reactor Operator (Monovinylacetylene Reactor Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the MVA Reactor Operator (Monovinylacetylene Reactor Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The MVA Reactor Operator is responsible for the safe and efficient operation of the MVA reactor, which produces monovinylacetylene, a key component in the production of polyvinyl chloride (PVC).

1. Reactor Operation

Monitors and controls the MVA reactor, ensuring that operating parameters are maintained within specified limits.

- Adjusts process variables such as temperature, pressure, and flow rates.

- Monitors the reactor feedstock, ensuring that the correct composition and quality are maintained.

2. Maintenance and Troubleshooting

Inspects and maintains reactor equipment, including pumps, valves, and instrumentation.

- Troubleshoots and resolves equipment malfunctions, ensuring minimal downtime.

- Conducts regular maintenance and repairs to prevent equipment failures.

3. Safety and Compliance

Adheres to all safety protocols and procedures as outlined by the company and industry regulations.

- Monitors and maintains a safe work environment.

- Reports any potential hazards or safety concerns to supervisors immediately.

4. Data Analysis and Reporting

Tracks and documents reactor data, including process parameters, feedstock consumption, and product quality.

- Analyzes data to identify potential areas for improvement in efficiency or safety.

- Prepares and submits reports on reactor performance and product quality to supervisors.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some key tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and current projects. Additionally, research the specific MVA Reactor Operator role and its responsibilities.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on relevant trends.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful and concise answers that highlight your relevant skills and experience.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Quantify your accomplishments with specific metrics whenever possible.

3. Be Confident and Enthusiastic

Confidence and enthusiasm are contagious and can make a lasting impression on interviewers. Demonstrate your passion for the field and your eagerness to contribute to the team.

- Maintain eye contact and speak clearly and assertively.

- Smile and show your genuine interest in the opportunity.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any uncertainties.

- Prepare questions about the company’s culture, growth opportunities, and specific challenges related to the role.

- Avoid asking questions about salary or benefits at this stage.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the MVA Reactor Operator (Monovinylacetylene Reactor Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!