Are you gearing up for a career in Nail Mill Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Nail Mill Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

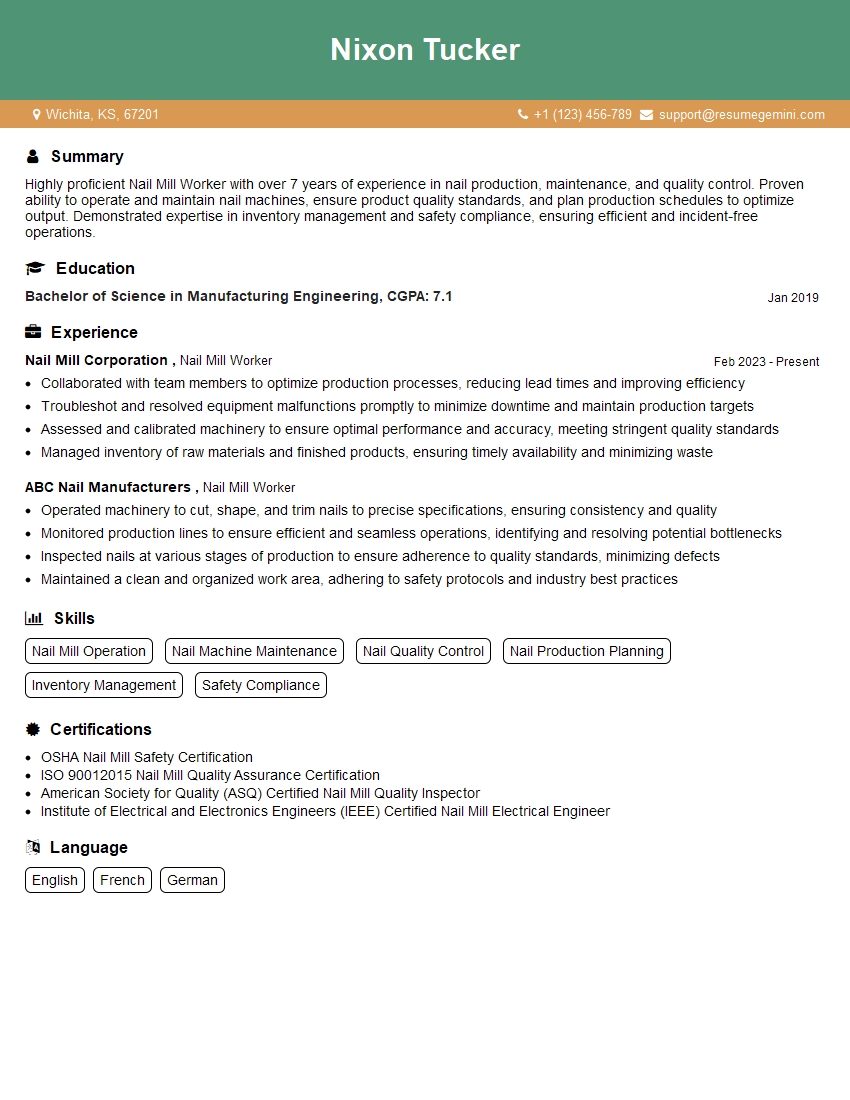

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nail Mill Worker

1. Describe the process of drawing a wire rod.

The process of drawing a wire rod starts with a hot rolled steel billet. The billet is heated to a high temperature and then passed through a series of dies that progressively reduce its diameter. As the wire rod is drawn, it is also cooled to prevent it from becoming too brittle. The final diameter of the wire rod can vary depending on the desired application.

2. What are the different types of nail heads?

There are several different types of nail heads, including:

- Flat head: This is the most common type of nail head. It is flat and has a slight countersink.

- Round head: This type of nail head is round and has a slight dome. It is often used for decorative purposes.

- Oval head: This type of nail head is oval and has a slight countersink. It is often used for finishing work.

- Countersunk head: This type of nail head is flat and has a deep countersink. It is often used for applications where the nail head needs to be hidden.

3. What are the safety precautions that must be taken when operating a nail mill?

There are several safety precautions that must be taken when operating a nail mill, including:

- Always wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Keep the work area clean and free of debris.

- Be aware of the location of all moving parts and avoid contact with them.

- Never operate the nail mill while intoxicated or under the influence of drugs.

- Follow all manufacturer’s instructions for the safe operation of the nail mill.

4. What are the different types of nails?

There are many different types of nails, each with its own specific purpose. Some of the most common types of nails include:

- Common nails: These are the most common type of nail and are used for a variety of applications, such as framing, sheathing, and siding.

- Finishing nails: These nails are smaller than common nails and are used for finishing work, such as trim, molding, and cabinetry.

- Brad nails: These nails are very small and are used for light-duty applications, such as attaching fabric to wood.

- Roofing nails: These nails are designed for use in roofing applications and have a large head that helps to keep the roofing material in place.

- Drywall nails: These nails are used for attaching drywall to wood or metal studs.

5. What are the different types of nail guns?

There are three main types of nail guns: pneumatic, electric, and cordless.

- Pneumatic nail guns are powered by compressed air and are the most powerful type of nail gun. They are often used for heavy-duty applications, such as framing and sheathing.

- Electric nail guns are powered by electricity and are less powerful than pneumatic nail guns. They are often used for lighter-duty applications, such as finishing work and trim.

- Cordless nail guns are powered by batteries and are the most portable type of nail gun. They are often used for applications where it is difficult or impossible to use a pneumatic or electric nail gun, such as working in tight spaces or on ladders.

6. How do you troubleshoot a nail mill?

If a nail mill is not operating properly, there are a few things that you can do to troubleshoot the problem:

- Check the power supply to the nail mill and make sure that it is turned on.

- Check the air pressure to the nail mill if it is a pneumatic model. Make sure that the air pressure is high enough to operate the nail mill.

- Check the nail magazine to make sure that it is loaded with nails.

- Check the nail driver to make sure that it is not jammed.

- Check the safety features on the nail mill to make sure that they are working properly.

7. What are the different types of nail mill tooling?

There are a variety of different types of nail mill tooling, including:

- Nail dies: These dies are used to shape the nails as they are drawn from the wire rod.

- Nail headers: These dies are used to form the heads of the nails.

- Nail cutters: These dies are used to cut the nails to the desired length.

- Nail polishers: These dies are used to smooth the surface of the nails and remove any burrs.

8. How do you maintain a nail mill?

To maintain a nail mill, it is important to:

- Keep the nail mill clean and free of debris.

- Lubricate the moving parts of the nail mill regularly.

- Inspect the nail mill regularly for any signs of wear or damage.

- Repair or replace any worn or damaged parts as needed.

9. What are the different types of nail mill defects?

There are a variety of different types of nail mill defects, including:

- Missed heads: This defect occurs when the nail head is not properly formed.

- Undersized heads: This defect occurs when the nail head is too small.

- Oversized heads: This defect occurs when the nail head is too large.

- Split shanks: This defect occurs when the nail shank splits.

- Bent shanks: This defect occurs when the nail shank is bent.

10. How do you control the quality of nails produced by a nail mill?

To control the quality of nails produced by a nail mill, it is important to:

- Use high-quality wire rod.

- Use the correct nail dies, nail headers, and nail cutters.

- Set the nail mill to the correct operating parameters.

- Inspect the nails regularly for any defects.

- Make adjustments to the nail mill as needed to maintain the desired quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nail Mill Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nail Mill Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nail Mill Workers are responsible for operating nail-making machines to produce nails of various sizes. Key responsibilities include:

1. Operating Machinery

• Loading raw materials, such as wire rods, into the machine’s hopper

• Monitoring the machine’s operation and making adjustments as needed

• Inspecting finished nails for quality and removing any defective products

2. Maintaining Equipment

• Regularly cleaning and lubricating machinery

• Identifying and addressing minor maintenance issues

• Reporting any major maintenance needs to supervisors

3. Maintaining Workplace Safety

• Following all safety protocols and procedures

• Wearing appropriate safety gear, such as gloves and eye protection

• Keeping the work area clean and organized

4. Other Duties

• Assisting in loading and unloading materials

• Keeping records of production and machine maintenance

• Performing other duties as assigned

Interview Tips

To ace your Nail Mill Worker interview, consider the following tips:

1. Research the Company and Position

• Familiarize yourself with the company’s products and services

• Understand the specific requirements of the Nail Mill Worker role

2. Practice Answering Common Interview Questions

• Prepare answers to questions about your experience, skills, and qualifications

• Use the STAR method (Situation, Task, Action, Result) to structure your responses

• Example: “Tell me about a time you solved a problem on a production line.”

• Answer: “In a previous role, a machine malfunctioned, causing production delays. I quickly identified the problem and implemented a solution, minimizing downtime and maintaining production targets.”

3. Emphasize Relevant Skills

• Highlight your experience and skills in operating nail-making machinery

• Demonstrate your understanding of machine maintenance, safety protocols, and quality control

4. Show Enthusiasm and Passion

• Express your interest in the Nail Mill Worker position and the manufacturing industry

• Share any personal experiences or interests that align with the role

5. Dress Appropriately and Arrive on Time

• Wear appropriate attire for the interview, such as business casual or a company uniform

• Punctuality demonstrates your professionalism and respect for the interviewer’s time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nail Mill Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!