Are you gearing up for an interview for a Nailing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nailing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

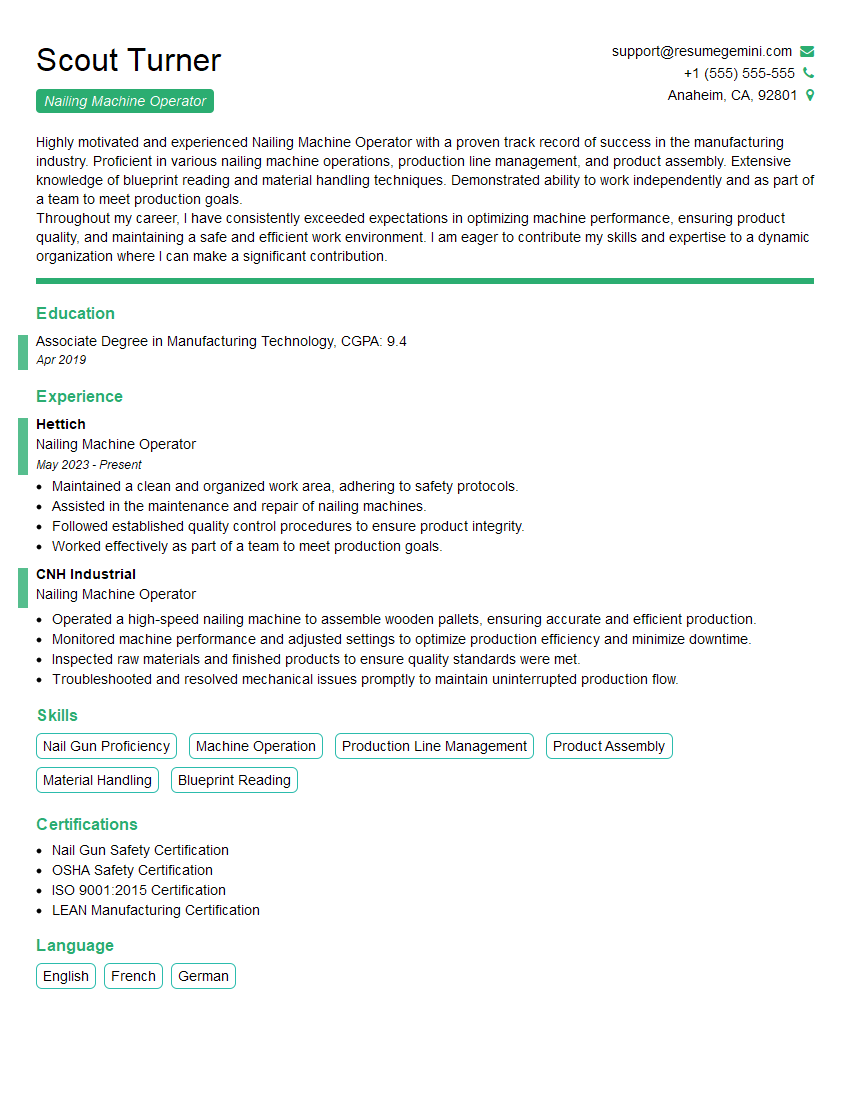

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nailing Machine Operator

1. What are the different types of nailing machines, and what are their applications?

There are several types of nailing machines, each with its own unique applications:

- Coil nailers: These nailers are used for high-volume nailing applications, such as framing and sheathing. They use a coil of nails that is fed into the machine automatically.

- Stick nailers: These nailers are used for smaller nailing jobs, such as finish carpentry and trim work. They use sticks of nails that are loaded into the magazine by hand.

- Brad nailers: These nailers are used for delicate nailing tasks, such as attaching molding and trim. They use small, thin nails called brads.

- Pin nailers: These nailers are used for very small nailing tasks, such as attaching upholstery and jewelry. They use tiny nails called pins.

2. What are the different types of nails that can be used in a nailing machine, and what are their different uses?

Common nails

- Used for general construction applications, such as framing and sheathing.

- Available in a variety of sizes and lengths.

Finishing nails

- Used for finish carpentry and trim work.

- Smaller and thinner than common nails.

Brad nails

- Used for delicate nailing tasks, such as attaching molding and trim.

- Very small and thin.

Pin nails

- Used for very small nailing tasks, such as attaching upholstery and jewelry.

- Tiny and thin.

3. What are the safety precautions that must be taken when operating a nailing machine?

There are several safety precautions that must be taken when operating a nailing machine to prevent injuries:

- Always wear safety glasses and gloves when operating a nailing machine.

- Never point the nailing machine at anyone.

- Keep your fingers away from the nailing point.

- Never use a nailing machine that is damaged or malfunctioning.

- Always follow the manufacturer’s instructions for operating the nailing machine.

4. What are the different maintenance tasks that need to be performed on a nailing machine?

To keep a nailing machine in good working condition, several maintenance tasks need to be performed regularly:

- Cleaning the machine regularly to remove dust and debris.

- Oiling the moving parts to reduce friction and wear.

- Inspecting the nails regularly to ensure they are not damaged or bent.

- Checking the air pressure regularly to ensure it is within the recommended range.

- Having the machine serviced by a qualified technician on a regular basis.

5. What are the troubleshooting steps that can be taken if a nailing machine is not working properly?

If a nailing machine is not working properly, several troubleshooting steps can be taken to identify and resolve the issue:

- Check the air pressure to ensure it is within the recommended range.

- Inspect the nails to ensure they are not damaged or bent.

- Clean the machine to remove any dust or debris that may be causing the problem.

- Oil the moving parts to reduce friction and wear.

- If the problem persists, consult the manufacturer’s instructions or contact a qualified technician for assistance.

6. What are the different types of nailing patterns that can be used in a nailing machine?

There are several different types of nailing patterns that can be used in a nailing machine, depending on the application:

- Straight nailing: This pattern is used for general construction applications, such as framing and sheathing.

- Staggered nailing: This pattern is used for applications where strength is required, such as in roof trusses and floor joists.

- Ring nailing: This pattern is used for applications where a decorative look is desired, such as in furniture and cabinetry.

- Toe nailing: This pattern is used to attach two pieces of wood at a right angle, such as in a door frame or window frame.

7. What are the factors that affect the quality of a nailed joint?

The quality of a nailed joint is affected by several factors:

- The type of nail used

- The size and length of the nail

- The nailing pattern

- The condition of the wood

- The skill of the operator

8. What are the different types of nailing machines that can be used for automated nailing?

There are several different types of nailing machines that can be used for automated nailing:

- Coil nailers: These nailers are used for high-volume nailing applications, such as framing and sheathing.

- Stick nailers: These nailers are used for smaller nailing jobs, such as finish carpentry and trim work.

- Brad nailers: These nailers are used for delicate nailing tasks, such as attaching molding and trim.

- Pin nailers: These nailers are used for very small nailing tasks, such as attaching upholstery and jewelry.

9. What are the advantages of using automated nailing machines?

Using automated nailing machines offers several advantages:

- Increased productivity

- Improved accuracy

- Reduced operator fatigue

- Enhanced safety

10. What are the factors to consider when selecting a nailing machine?

When selecting a nailing machine, several factors should be considered:

- The type of nailing application

- The volume of nailing

- The desired level of automation

- The budget

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nailing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nailing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nailing Machine Operators are responsible for the safe and efficient operation of nailing machines, which are used to join pieces of wood together. They must be able to set up the machine, load the wood, and operate the machine safely. They must also inspect the finished product to ensure that it meets quality standards.

1. Set up the nailing machine

The Nailing Machine Operator must be able to set up the machine according to the specifications for the job. This includes setting the machine speed, the nail size, and the nail spacing. They must also be able to load the wood into the machine and secure it in place.

2. Operate the machine safely

The Nailing Machine Operator must be able to operate the machine safely. This includes following all safety procedures and wearing the appropriate safety gear. They must also be able to identify and correct any problems with the machine.

3. Inspect the finished product

The Nailing Machine Operator must be able to inspect the finished product to ensure that it meets quality standards. This includes checking the nail size, the nail spacing, and the overall appearance of the product. They must also be able to identify and correct any defects.

4. Maintain the machine

The Nailing Machine Operator must be able to maintain the machine according to the manufacturer’s specifications. This includes cleaning the machine, lubricating the moving parts, and replacing any worn or damaged parts.

Interview Tips

Preparing for an interview for a Nailing Machine Operator position can be daunting, but it is important to remember that the interviewer is looking for someone who is qualified and experienced, but also someone who is a good fit for the company. Here are a few tips to help you ace your interview:

1. Research the company

Before you go to your interview, take some time to research the company. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can research the company’s website and LinkedIn page, and you can also read industry news articles to learn more about the company’s recent developments.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and polished shoes. You should also make sure that your hair is neat and tidy.

4. Be on time

Punctuality is important for any job interview, but it is especially important for a Nailing Machine Operator position. This is because the interviewer will want to see that you are reliable and that you can manage your time effectively.

5. Be yourself

The most important thing is to be yourself and to let the interviewer see who you are. Don’t try to be someone you’re not, because the interviewer will be able to tell. Just relax, be confident, and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Nailing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.