Are you gearing up for an interview for a Naphtha Washing System Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Naphtha Washing System Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

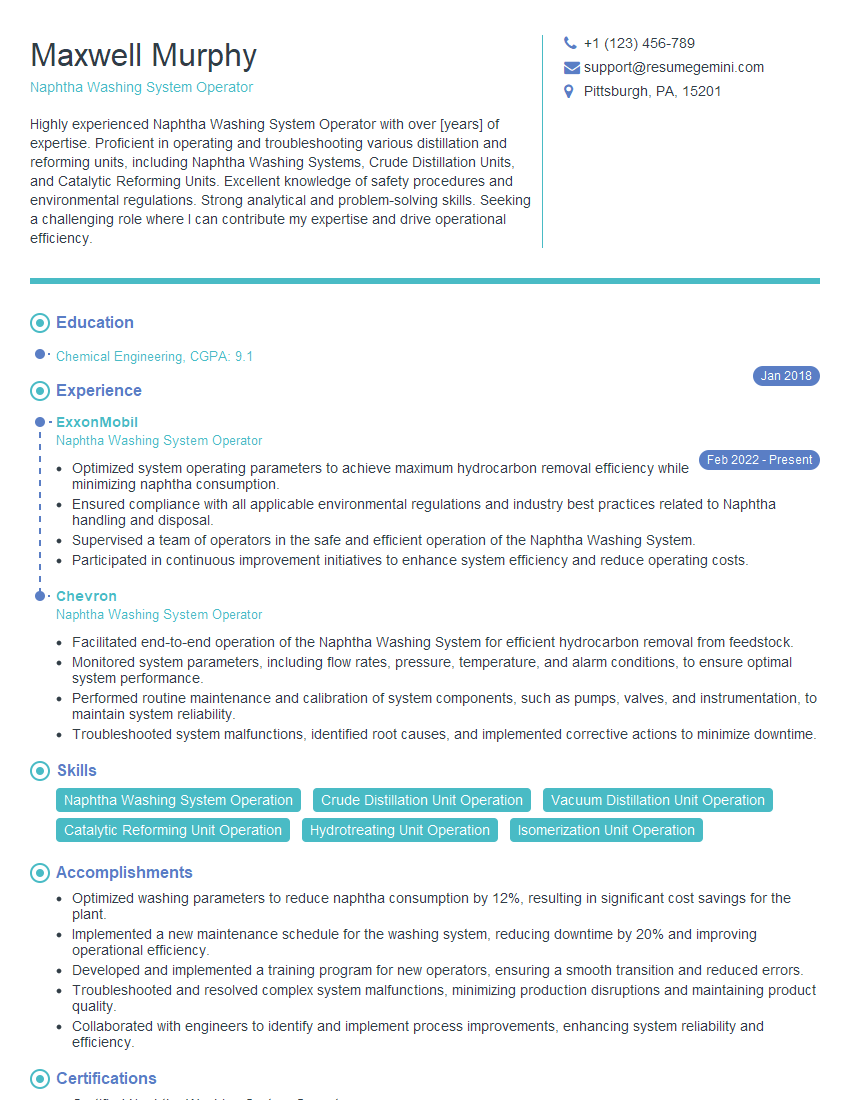

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Naphtha Washing System Operator

1. Explain the process of naphtha washing.

Naphtha washing is a process used to remove impurities from a feedstock. The process involves contacting the feedstock with naphtha, which is a light hydrocarbon. The naphtha absorbs the impurities, which are then removed from the feedstock.

2. What are the key operating parameters of a naphtha washing system?

Temperature

- The temperature of the naphtha washing system is important because it affects the solubility of the impurities in the naphtha.

- The higher the temperature, the more soluble the impurities will be in the naphtha.

Pressure

- The pressure of the naphtha washing system is also important because it affects the rate of mass transfer between the naphtha and the feedstock.

- The higher the pressure, the faster the rate of mass transfer will be.

Contact time

- The contact time between the naphtha and the feedstock is also important because it affects the amount of impurities that are removed from the feedstock.

- The longer the contact time, the more impurities that will be removed from the feedstock.

3. What are the common problems that can occur in a naphtha washing system?

- Plugging of the naphtha washing system

- Corrosion of the naphtha washing system

- Leaking of the naphtha washing system

4. What are the safety considerations that must be taken into account when operating a naphtha washing system?

- Naphtha is a flammable liquid, so it is important to take precautions to prevent fires.

- Naphtha is also a toxic substance, so it is important to take precautions to prevent exposure to the naphtha.

5. What are the maintenance procedures that must be performed on a naphtha washing system?

- The naphtha washing system should be inspected regularly for any signs of damage or wear.

- The naphtha washing system should be cleaned regularly to remove any build-up of impurities.

6. What are the troubleshooting procedures that can be used to resolve problems with a naphtha washing system?

- If the naphtha washing system is plugged, the plugging can be removed by using a chemical solvent.

- If the naphtha washing system is corroded, the corrosion can be repaired by using a corrosion-resistant coating.

- If the naphtha washing system is leaking, the leak can be repaired by using a sealant.

7. What are the environmental regulations that apply to naphtha washing systems?

- The environmental regulations that apply to naphtha washing systems vary from country to country.

- In the United States, the naphtha washing system must be operated in accordance with the Clean Air Act and the Clean Water Act.

8. What are the quality control procedures that must be performed on the output of a naphtha washing system?

- The output of the naphtha washing system should be tested to ensure that it meets the desired specifications.

- The output of the naphtha washing system should be monitored for any signs of contamination.

9. What are the training requirements for naphtha washing system operators?

- Naphtha washing system operators must be trained in the safe operation of the system.

- Naphtha washing system operators must be trained in the maintenance of the system.

- Naphtha washing system operators must be trained in the troubleshooting of the system.

10. What are the career advancement opportunities for naphtha washing system operators?

- Naphtha washing system operators can advance to positions such as supervisor, manager, or engineer.

- Naphtha washing system operators can also start their own businesses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Naphtha Washing System Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Naphtha Washing System Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Naphtha Washing System Operators are responsible for operating and maintaining the equipment used to remove impurities from crude naphtha, a petroleum derivative. Their key responsibilities include:

1. Equipment Operation

Ensuring the safe and efficient operation of all equipment within the naphtha washing system, including pumps, tanks, valves, and control systems.

- Monitoring and adjusting system parameters to optimize naphtha purity and yield.

- Implementing and maintaining preventive maintenance programs to ensure system reliability and uptime.

2. Process Monitoring

Continuously monitoring system performance and key process parameters, such as temperature, pressure, and flow rates, to ensure product quality and system efficiency.

- Identifying and troubleshooting deviations from normal operating conditions, implementing corrective actions to maintain system stability.

- Collecting and analyzing process data to identify areas for improvement and optimize system performance.

3. Naphtha Quality Control

Ensuring that the naphtha produced meets the required specifications for purity and contamination levels through various inspections and tests.

- Conducting sampling and testing of naphtha to monitor quality parameters and identify impurities.

- Implementing quality control measures and protocols to prevent contamination and ensure product quality.

4. Health, Safety, and Environmental Compliance

Adhering to all applicable health, safety, and environmental regulations related to the operation of the naphtha washing system.

- Utilizing personal protective equipment and following established safety protocols to minimize risks and protect personnel and the environment.

- Monitoring and managing emissions and waste streams to ensure compliance with environmental regulations.

Interview Tips

To ace the interview for a Naphtha Washing System Operator position, it’s important to thoroughly prepare and demonstrate your skills and knowledge. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s operations, products, and values. Research the specific role and its requirements to gain a clear understanding of the expectations.

- Visit the company’s website, LinkedIn page, and industry publications to gather information.

- Prepare questions to ask the interviewer about the company, team, and challenges faced in the role.

2. Highlight Your Technical Skills

Emphasize your expertise in operating and maintaining naphtha washing systems, including your knowledge of process parameters, equipment troubleshooting, and quality control.

- Provide specific examples of your experience in handling similar systems, resolving operational issues, and implementing improvements.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your contributions.

3. Show Your Problem-Solving Abilities

Interviewers are keen on assessing your problem-solving skills. Describe situations where you encountered unexpected challenges and how you applied your knowledge and creativity to find solutions.

- Use the STAR method (Situation, Task, Action, Result) to outline your experiences, highlighting your analytical thinking and decision-making process.

- Focus on the outcomes and the positive impact of your actions on system performance or product quality.

4. Emphasize Safety and Compliance

Underscore your commitment to safety and adherence to industry regulations. Highlight your experience in utilizing protective gear, following protocols, and managing environmental aspects of the naphtha washing process.

- Explain how you stay up-to-date with safety best practices and regulations specific to the industry.

- Provide examples of your proactive approach to risk management and environmental protection.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Naphtha Washing System Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!