Are you gearing up for a career in Naphthalene Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Naphthalene Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

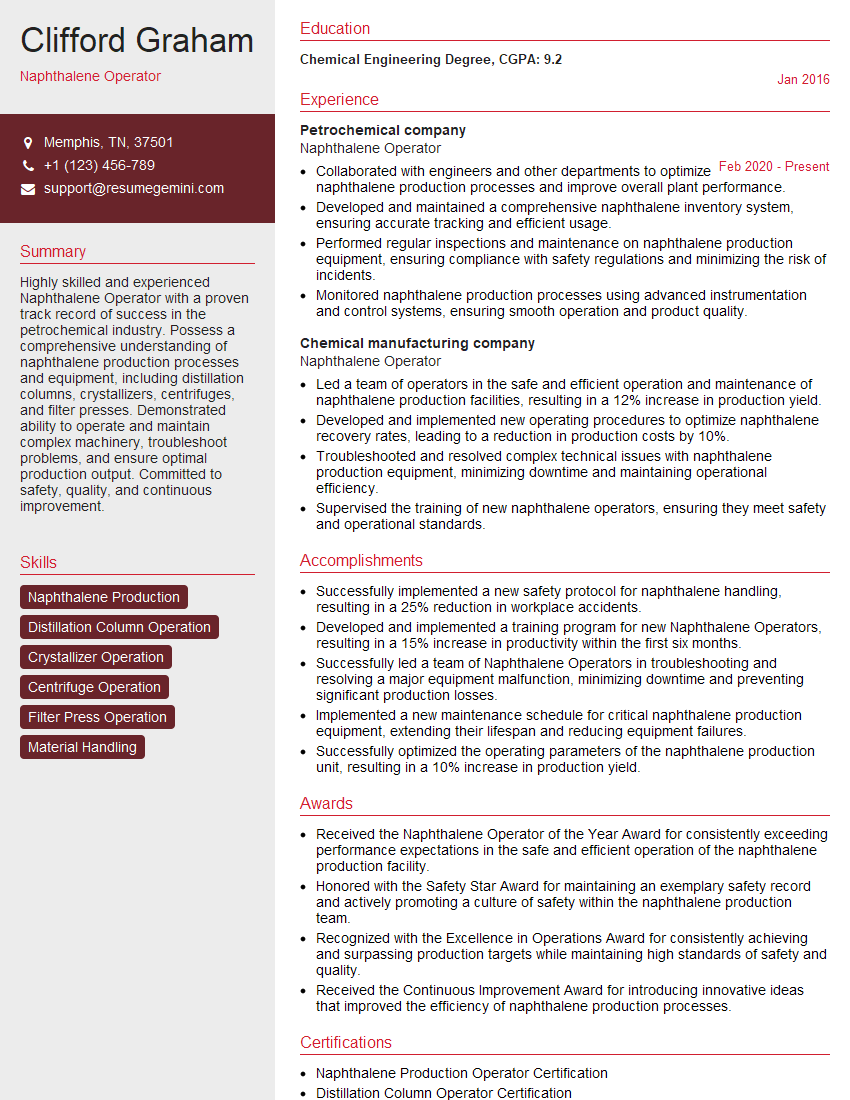

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Naphthalene Operator

1. Explain the process of Naphthalene production?

- Raw material preparation: Naphthalene is produced from coal tar or petroleum by fractional distillation.

- Purification: The distillate is further purified by crystallization, which removes impurities and improves the quality of the naphthalene.

- Sublimation: The purified naphthalene is sublimed, which involves heating it to a temperature where it vaporizes and then condenses to form crystals.

- Packaging: The naphthalene crystals are packaged in airtight containers to prevent sublimation and contamination.

2. What are the safety precautions and hazards associated with Naphthalene handling?

Physical hazards

- Naphthalene is a flammable solid and can ignite easily.

- It has a high sublimation point, meaning it can easily vaporize and form an explosive atmosphere.

Health hazards

- Naphthalene is toxic if ingested, inhaled, or absorbed through the skin.

- Long-term exposure can lead to eye irritation, skin irritation, and respiratory problems.

Environmental hazards

- Naphthalene is harmful to aquatic life and can accumulate in the environment.

3. Describe the types of equipment used in Naphthalene production?

- Distillation column: Used to separate naphthalene from other components in coal tar or petroleum.

- Crystallizer: Used to remove impurities from the distillate.

- Sublimator: Used to convert naphthalene into crystals.

- Packaging machine: Used to fill naphthalene crystals into containers.

4. Explain the quality control procedures for Naphthalene production?

- Raw material testing: The quality of the coal tar or petroleum is tested to ensure it meets the required specifications.

- Process monitoring: The production process is monitored to ensure that all parameters are within the desired range.

- Product testing: The final product is tested to ensure that it meets the required quality standards.

5. What are the challenges and difficulties associated with Naphthalene production?

- Fire and explosion hazards: Naphthalene is a flammable solid and can easily ignite, posing a safety risk.

- Environmental concerns: Naphthalene is harmful to aquatic life and can accumulate in the environment, requiring proper waste management.

- Product purity: Removing impurities from naphthalene can be challenging, as it requires precise control of the production process.

6. How do you maintain and calibrate the equipment used in Naphthalene production?

- Regular inspections: Equipment should be inspected regularly for wear and tear, leaks, and other issues.

- Calibration: Equipment should be calibrated regularly to ensure accuracy and reliability.

- Preventive maintenance: Regular maintenance tasks, such as cleaning, lubrication, and adjustments, should be performed to extend equipment life and prevent breakdowns.

7. Describe your role and responsibilities as a Naphthalene Operator?

- Operate and monitor equipment: Operate and monitor distillation columns, crystallizers, sublimators, and packaging machines.

- Maintain equipment: Perform regular maintenance and calibration of equipment to ensure optimal performance.

- Ensure safety: Implement and adhere to safety protocols to prevent accidents and minimize risks.

- Collect and record data: Collect and record production data, equipment performance data, and quality control data.

8. How do you handle emergencies and unplanned events during Naphthalene production?

- Assess the situation: Quickly assess the situation and identify the potential risks and hazards.

- Act promptly: Take immediate action to mitigate the emergency, such as shutting down equipment or initiating safety protocols.

- Communicate effectively: Inform supervisors and relevant personnel about the emergency and provide regular updates.

- Investigate and learn: Conduct a thorough investigation to determine the root cause of the emergency and implement corrective actions to prevent recurrence.

9. What are the environmental regulations and safety standards that apply to Naphthalene production?

- Occupational Safety and Health Administration (OSHA) regulations: These regulations cover workplace safety, including handling hazardous materials such as naphthalene.

- Environmental Protection Agency (EPA) regulations: These regulations address air pollution, water pollution, and waste management related to naphthalene production.

- Local and state regulations: There may be additional regulations specific to the location of the production facility.

10. How do you stay up-to-date with advances in Naphthalene production technology and best practices?

- Attend industry conferences and workshops: Engage in professional development opportunities to learn about new technologies and best practices.

- Read industry publications: Stay informed about the latest research and advancements in naphthalene production.

- Network with other professionals: Collaborate with peers and experts in the field to share knowledge and experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Naphthalene Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Naphthalene Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Naphthalene Operator

The Naphthalene Operator is responsible for the safe, reliable, and efficient operation of the naphthalene plant. This includes the following key job responsibilities:

1. Plant Operations

Responsible for starting up, shutting down, and restarting plant processes to meet customer demand within the approved operating guidelines.

- Monitor and interpret the operating states of equipment and initiate corrective actions.

- Monitor control panels and rectify deviations outside of product specifications.

- Investigate process deviations and implement appropriate corrective actions to resolve in a timely manner.

2. Plant Maintenance

Conducts basic plant maintenance, mechanical, and field electrical repairs, and installs spare parts as required.

- Perform equipment inspections and lubrication and take appropriate actions.

- Troubleshoot minor electrical problems, replace electrical components, and maintain and repair electrical equipment.

- Calibrate and maintain control equipment, including controllers, transmitters, and analyzers.

3. Safety and Environmental Compliance

Ensures the safe and environmentally compliant operation of the plant.

- Identify and assess potential hazards, including chemical, physical, and biological.

- Follow company policies and procedures related to safety, environmental compliance, and security.

- Notify supervisor and emergency services promptly in case of any accident or incident.

4. Other Responsibilities

Perform other duties as required to support the safe and efficient operation of the plant.

- Participate in shift handovers and meetings.

- Assist with training new employees.

- Perform housekeeping and yard maintenance of the plant area.

Interview Preparation Tips for Naphthalene Operator Candidates

To help candidates ace the interview for a Naphthalene Operator position, here are some preparation tips and hacks:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and the key responsibilities of the position.

2. Practice Your Answers to Common Interview Questions

There are certain common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this role?” Practice answering these questions in a clear and concise manner.

3. Highlight Your Skills and Experience

When answering interview questions, be sure to highlight your skills and experience that are relevant to the Naphthalene Operator role. For example, emphasize your experience in operating and maintaining plant equipment, your knowledge of safety and environmental regulations, and your ability to work independently and as part of a team.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the role. Prepare some questions in advance that will help you learn more about the company, the role, and the team you would be working with.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for the interview. Also, be sure to arrive on time to show that you are respectful of the interviewer’s time.

6. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you are excited about the opportunity and that you would be a valuable asset to the team.

By following these tips, you will increase your chances of success in the interview for a Naphthalene Operator position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Naphthalene Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.